Preparation method of walnut shell-doped sludge activated carbon

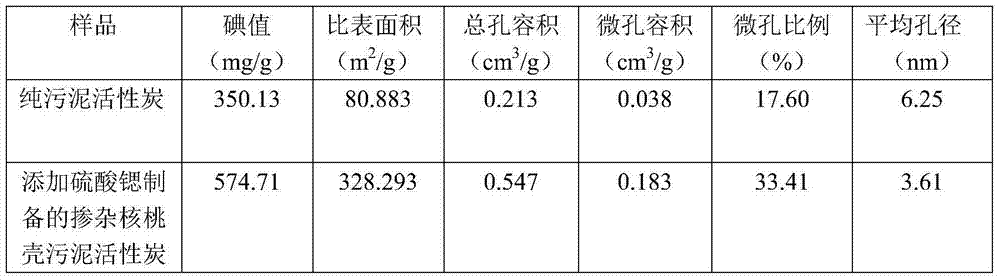

A sludge activated carbon and walnut shell technology, which is applied in the field of one-step carbonization and activation to prepare sludge activated carbon, to achieve the effect of increasing micropore volume, stabilization and developed pores

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0015] (1) Dry the excess sludge with a moisture content of 80.6% to a moisture content of 8% to obtain dry sludge; crush and sieve the dry sludge and walnut shells respectively to obtain sludge and walnuts with a particle size of 0.3 to 0.8mm For shell particles, take 9.00g of sludge particles and 1.00g of walnut shell particles, and mix them evenly.

[0016] (2) Add 0.02g of strontium sulfate powder to the sludge raw material doped with walnut shells obtained in step 1, and mix evenly.

[0017] (3) Add the raw material mixture obtained in step 2 into the zinc chloride solution and stir evenly, impregnate it at room temperature for 24 hours, and dry it for 24 hours at 80°C. The concentration of the zinc chloride solution used for impregnation is 2.0mol / L, and the impregnation mass ratio is 1:2.5.

[0018] (4) Put the intermediate product obtained in step 3 into a box-type resistance furnace, raise the temperature to 400° C. at a heating rate of 5° C. / min, and keep the temper...

Embodiment 2

[0022] (1) Dry the excess sludge with a moisture content of 80.6% to a moisture content of 10% to obtain dry sludge; crush and sieve the dry sludge and walnut shells respectively to obtain sludge and walnuts with a particle size of 0.3 to 0.8 mm For shell particles, take 8.00g of sludge particles and 2.00g of walnut shell particles, and mix them evenly.

[0023] (2) Add 0.04g of strontium sulfate powder to the sludge raw material doped with walnut shells obtained in step 1, and mix evenly.

[0024] (3) Add the raw material mixture obtained in step 2 into the zinc chloride solution and stir evenly to impregnate it for 24 hours at room temperature, and then dry it for 24 hours at 80°C. 1:2.5.

[0025] (4) Put the intermediate product obtained in step 3 into a box-type resistance furnace, raise the temperature to 500° C. at a heating rate of 10° C. / min, and keep the temperature constant for 60 minutes.

[0026] (5) After cooling the activated carbide obtained in step 4 to room ...

Embodiment 3

[0029] (1) Dry the excess sludge with a moisture content of 80.6% to a moisture content of 8% to obtain dry sludge; crush and sieve the dry sludge and walnut shells respectively to obtain sludge and walnuts with a particle size of 0.3 to 0.8mm For shell particles, take 7.00g of sludge particles and 3.00g of walnut shell particles, and mix the two evenly.

[0030] (2) Add 0.06g of strontium sulfate powder to the sludge raw material doped with walnut shells obtained in step 1, and mix evenly.

[0031] (3) Add the raw material mixture obtained in step 2 into the zinc chloride solution and stir evenly, impregnate it at room temperature for 24 hours, and dry it for 24 hours at 80°C. The concentration of the zinc chloride solution used for the impregnation is 3.0mol / L, and the impregnation mass ratio is 1:2.5.

[0032] (4) Put the intermediate product obtained in step 3 into a box-type resistance furnace, raise the temperature to 450° C. at a heating rate of 10° C. / min, and keep th...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com