Descaling and blockage-removing fluid for clearing blockage in drilling and completion process and preparation method of descaling and blockage-removing fluid

A technology for drilling, completion and plugging removal, which is applied in the direction of drilling compositions, chemical instruments and methods, cleaning tools, etc. It can solve problems such as easy to block reservoirs, difficult flowback, and corroded production casings, etc., to achieve plugging removal good effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0031] The preparation method of the high temperature resistant anti-swelling agent used is: dissolving 20g of trimethylamine in 100mL of ethanol, adding 60g of 37.5% hydrochloric acid, stirring at normal temperature for 1h to obtain the mixed solution I of trimethylamine hydrochloride; Add 10g of fatty acid ester (16C-18C) to the mixture, continue to stir until the solution is uniform, and obtain mixed solution II; then add 40g of epichlorohydrin dropwise to the mixed solution II, after the addition is completed, add 0.09g, (NH 4 ) 2 S 2 o 8 -NaHSO 3 Stir continuously and heat up to 60°C, stop the reaction after reflux for 5h, and obtain a mixed solution III containing a quaternary ammonium organic cationic polymer; finally add potassium chloride of 60% of the total mass of the mixed solution III to the mixed solution III and mix well , evaporate the solvent to get the anti-high temperature anti-expansion agent for fracturing

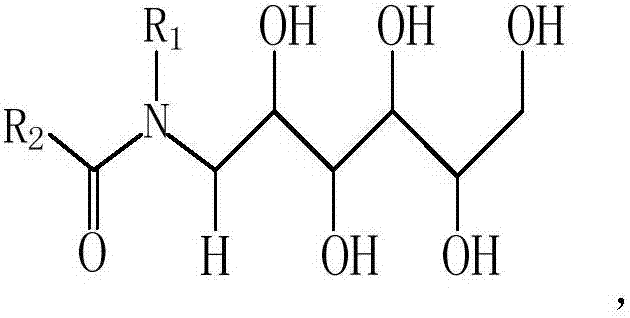

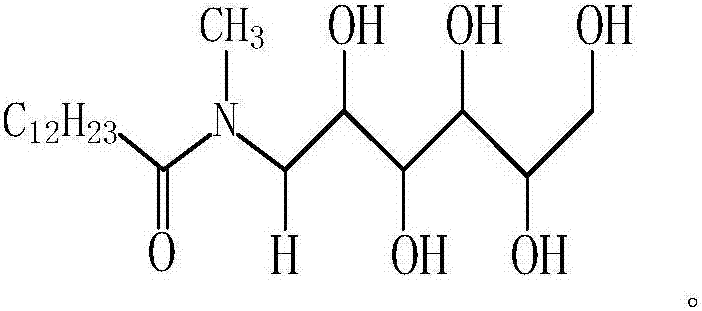

[0032] The alkylglucamide used specifically ...

Embodiment 1

[0035] Weigh 55.5 parts of water, 20 parts of DTPA-5Na and 2 parts of KOH into the reactor and mix and stir to form a uniform mixed solution; then add 2 parts of high temperature resistant anti-swelling agent, 3 parts of sodium thiosulfate, 4 parts of Sodium gluconate, 4.5 parts of alkyl glucamide and 4 parts of phosphate surfactant, stir for 1 to 2 hours until each component is completely dissolved; finally add 5 parts of proteolytic enzyme, stir for 30 minutes until evenly mixed, and then get the descaling Blockage solution A.

[0036] After testing, the density of the descaling and plugging solution A is 1.06g / cm 3 , the pH is 10, the surface tension is less than 30mN / m, and the anti-swelling rate of clay is more than 90%.

[0037] The scale removal effect test and the blockage removal effect test were carried out on the descaling and plugging removal solution A prepared in Example 1. specifically,

[0038]The method of descaling effect test is: take by weighing 10g oil ...

Embodiment 2

[0042] Weigh 41 parts of water, 38 parts of DTPA-5Na and 3.5 parts of KOH into the reactor and mix and stir to form a uniform mixed solution; then add 1 part of high temperature resistant anti-swelling agent, 3.5 parts of sodium thiosulfate, 2 parts of Lactic acid, 3 parts of alkylglucamide and 4 parts of phosphoric acid ester surfactant, stir for 1 to 2 hours until all components are completely dissolved; finally add 4 parts of glutamic acid transferase, stir for 30 minutes until the mixture is uniform, and the descaling Blockage solution B.

[0043] After testing, the density of the descaling and plugging solution B is 1.08g / cm 3 , pH 12, surface tension <30mN / m, clay anti-swelling rate ≥ 85%.

[0044] The scale removal effect test and the blockage removal effect test were carried out on the descaling and plugging removal solution B prepared in Example 2. Concrete test method is identical with the method that embodiment 1 adopts.

[0045] Descaling effect test: the test t...

PUM

| Property | Measurement | Unit |

|---|---|---|

| density | aaaaa | aaaaa |

| surface tension | aaaaa | aaaaa |

| density | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com