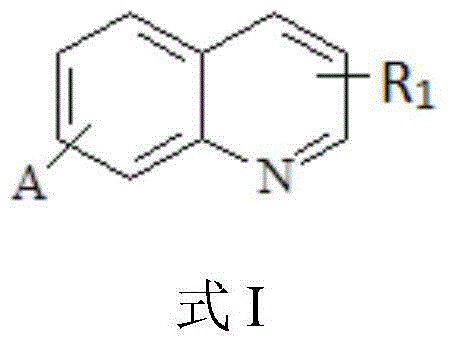

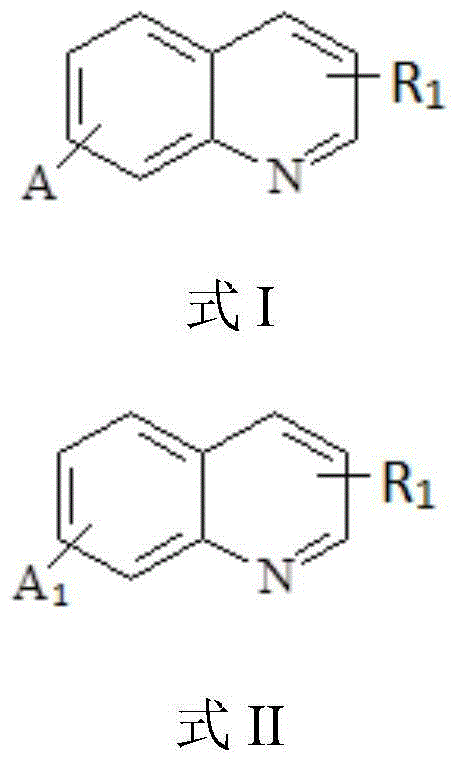

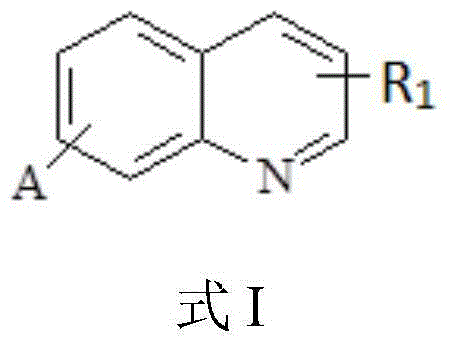

Quinoline deviate and preparation method and application thereof and corrosion and scale inhibitor composition

A technology of corrosion and scale inhibitors and derivatives, applied in drilling compositions, chemical instruments and methods, earthwork drilling and production, etc., can solve problems such as water injection wellbore protection research, achieve excellent corrosion and scale inhibition performance, excellent Corrosion and scale inhibition, easy to degrade effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0046] This example was used to prepare 2-methyl-5-polyoxyethylene-quinoline.

[0047] Add 19.2g of 2-methyl-5-hydroxyquinoline (chemical reagent, TCI (Shanghai) Chemical Industry Development Co., Ltd.), catalyst (sodium hydroxide, 0.1 g) into the reactor, close the reactor, and replace with nitrogen Air in the kettle, stirring, heating up to 120° C., slowly press in about 44 grams of ethylene oxide, and then continue the reaction for two hours. Cool down to get the product. NMR 13 The analysis results of C showed that the peaks with chemical shifts of 67-72 were the formed ether bonds.

Embodiment 2

[0049] This example was used to prepare 3-methyl-6-polyoxyethylene-quinoline.

[0050] Add 19.2g of 3-methyl-6-hydroxyquinoline (chemical reagent, TCI (Shanghai) Chemical Industry Development Co., Ltd.), catalyst (sodium hydroxide, 0.1 g) into the reactor, close the reactor, and replace with nitrogen Air in the kettle, stirring, heating up to 120°C, slowly press in about 27 grams of ethylene oxide, and then continue the reaction for two hours. Cool down to get the product. NMR 13 The analysis results of C showed that the peaks with chemical shifts of 67-72 were the formed ether bonds.

Embodiment 3

[0052] This example was used to prepare 4-methyl-7-polyoxyethylene-quinoline.

[0053] Add 19.2g of 4-methyl-7-hydroxyquinoline (chemical reagent, TCI (Shanghai) Chemical Industry Development Co., Ltd.), catalyst (sodium hydroxide, 0.1 g) into the reactor, close the reactor, and replace with nitrogen Air in the kettle, stirring, heating up to 120°C, slowly press in about 88 grams of ethylene oxide, and then continue the reaction for two hours. Cool down to get the product. NMR 13 The analysis results of C showed that the peaks with chemical shifts of 67-72 were the formed ether bonds.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com