Corrosion inhibitor for cooling water of marine diesel engine and preparation method thereof

A technology for diesel engines and corrosion inhibitors, applied in chemical instruments and methods, organic chemistry, descaling and water softening, etc., can solve the problems affecting heat transfer efficiency and equipment life, inorganic salt scaling, aluminum and aluminum alloy protection Weakness and other problems, to achieve the effect of inhibiting the surface dirt inside the condensate pipe, good scale inhibition performance, and continuous and effective heat transfer efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

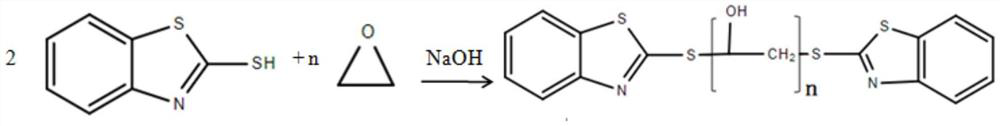

[0030] A method for preparing a corrosion inhibitor for marine diesel engine cooling water, which comprises the following steps:

[0031] Step (1) pre-reaction treatment process: thoroughly clean the three-necked flask, stirring paddle, etc., check the tightness of the system, ensure that the sealing is good, and the stirring and other operations are normal;

[0032] Add 334.0g of 2-mercaptobenzothiazole (MBT) and 0.4g of sodium hydroxide to the three-necked flask, add an appropriate amount of 100g of water to dissolve the sodium hydroxide to ensure that the pH of the reaction system is greater than or equal to 9, and then seal the inside of the three-necked flask to evacuated to Below -0.09mPa, make the inside of the three-necked flask under the condition of negative pressure, and then suck 4.6g of ethanol into the three-necked flask under negative pressure and stir until the 2-mercaptobenzothiazole is completely dissolved;

[0033] Step (2) Reaction process: the three-necked...

Embodiment 2

[0036] A method for preparing a corrosion inhibitor for marine diesel engine cooling water, which comprises the following steps:

[0037] Step (1) pre-reaction treatment process: thoroughly clean the three-necked flask, stirring paddle, etc., check the tightness of the system, ensure that the sealing is good, and the stirring and other operations are normal;

[0038] Add 534.4g of 2-mercaptobenzothiazole (MBT) and 0.4g of sodium hydroxide to the three-necked flask, add an appropriate amount of 100g of water to dissolve the sodium hydroxide to ensure that the pH of the reaction system is greater than or equal to 9, and then seal the three-necked flask and vacuumize the interior to Below -0.09mPa, make the inside of the three-necked flask under the condition of negative pressure, and then suck 4.6g of ethanol into the three-necked flask under negative pressure and stir until the 2-mercaptobenzothiazole is completely dissolved;

[0039] Step (2) Reaction process: the three-necked...

Embodiment 3

[0042] A method for preparing a corrosion inhibitor for marine diesel engine cooling water, which comprises the following steps:

[0043]Step (1) pre-reaction treatment process: thoroughly clean the three-necked flask, stirring paddle, etc., check the tightness of the system, ensure that the sealing is good, and the stirring and other operations are normal;

[0044] Add 417.5g of 2-mercaptobenzothiazole (MBT) and 0.4g of sodium hydroxide to the three-necked flask, add an appropriate amount of 100g of water to dissolve the sodium hydroxide to ensure that the pH of the reaction system is greater than or equal to 9, and then seal the three-necked flask and vacuumize the interior to Below -0.09mPa, make the inside of the three-necked flask under the condition of negative pressure, and then suck 4.6g of ethanol into the three-necked flask under negative pressure and stir until the 2-mercaptobenzothiazole is completely dissolved;

[0045] Step (2) reaction process: the three-necked ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com