Corrosion and scale inhibitor composition, application thereof, and oil field water injection wellbore corrosion and scale prevention method

The technology of a corrosion and scale inhibitor and a composition is applied in the field of corrosion and scale inhibition of oilfield water injection wellbore, which can solve the problems of aggravated corrosion, complex composition of corrosion inhibitor, microbial corrosion, etc., and achieves simple composition and excellent corrosion and scale inhibition effect. , the effect of reducing difficulty

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0093] The 2-methyl-5-polyoxyethylene-quinoline used in this example was prepared by the following method.

[0094] 19.2g 2-methyl-5-hydroxyquinoline (chemical reagent, TCI (Shanghai) Chemical Industry Development Co., Ltd.), catalyst (sodium hydroxide, 0.1 gram) joins in the reaction kettle, closes the reaction kettle, replaces with nitrogen Air in the kettle, stirred, and the temperature was raised to 120° C., and about 44 grams of ethylene oxide was slowly pressed in, and then the reaction was continued for two hours. After cooling down, the solvent was removed, and the obtained solid matter was 13 Analysis by C-NMR showed that the peak with a chemical shift of 67-72 was the formed ether bond, and it was confirmed that the obtained solid substance was 2-methyl-5-polyoxyethylene-quinoline.

[0095] The corrosion and scale inhibitor composition used and the addition amount of each component are:

[0096] 2-methyl-5-polyoxyethylene-quinoline 30mg / L,

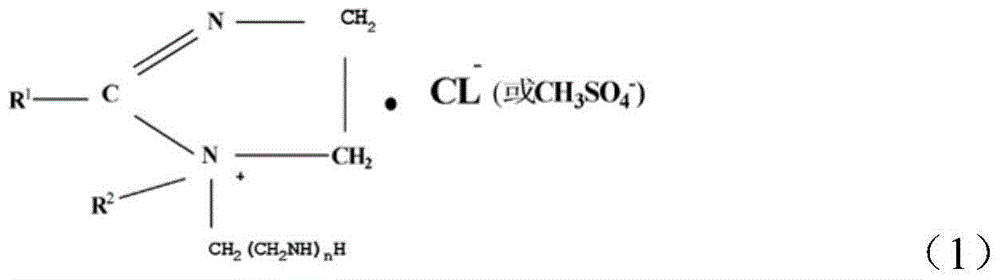

[0097] Heptadecenyl im...

Embodiment 2

[0126] The 3-methyl-6-polyoxyethylene-quinoline used in this example was prepared by the following method.

[0127] 19.2g 3-methyl-6-hydroxyquinoline (chemical reagent, TCI (Shanghai) Chemical Industry Development Co., Ltd.), catalyst (sodium hydroxide, 0.1 gram) joins in the reactor, closes the reactor, replaces with nitrogen Air in the kettle, stirring, heating up to 120°C, slowly press in about 27 grams of ethylene oxide, and then continue the reaction for two hours. Cool down to get the product. NMR 13 The analysis results of C showed that the peaks with chemical shifts of 67-72 were the formed ether bonds.

[0128] The corrosion and scale inhibitor composition used and the addition amount of each component are:

[0129] 3-methyl-6-polyoxyethylene-quinoline 40mg / L

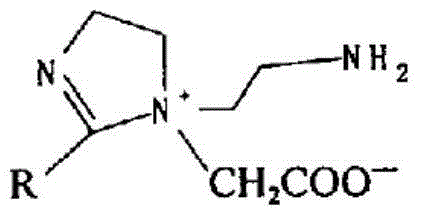

[0130] 1-aminoethyl-2-heptadecenyl imidazoline quaternary ammonium salt 10mg / L

[0131] Acrylic acid copolymer 3mg / L

[0132] 1-aminoethyl-2-heptadecenyl imidazoline quaternary ammonium salt has the follo...

Embodiment 3

[0138] The 4-methyl-7-polyoxyethylene-quinoline used in this example was prepared by the following method.

[0139] 19.2g 4-methyl-7-hydroxyquinoline (chemical reagent, TCI (Shanghai) Chemical Industry Development Co., Ltd.), catalyst (sodium hydroxide, 0.1 gram) joins in the reactor, closes the reactor, replaces with nitrogen Air in the kettle, stirring, heating up to 120°C, slowly press in about 88 grams of ethylene oxide, and then continue the reaction for two hours. Cool down to get the product. NMR 13 The analysis results of C showed that the peaks with chemical shifts of 67-72 were the formed ether bonds.

[0140] The corrosion and scale inhibitor composition used and the addition amount of each component are:

[0141] 4-methyl-7-polyoxyethylene-quinoline 35mg / L

[0142] Bisimidazoline 4mg / L

[0143] Acrylic acid copolymer 5mg / L

[0144] Bisimidazoline was purchased from Qinhuangdao Shengli Chemical Factory, the brand name is DLPM.

[0145] The acrylic acid copolyme...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com