Composite corrosion and scale inhibitor and application thereof

A technology of corrosion and scale inhibitors and corrosion inhibitors, applied in the fields of scale removal and water softening, water/sludge/sewage treatment, chemical instruments and methods, etc., can solve the problems of limited use of high phosphorus-containing chemical formulations, etc. Achieve the best corrosion and scale inhibition effect, environmental friendliness and excellent performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

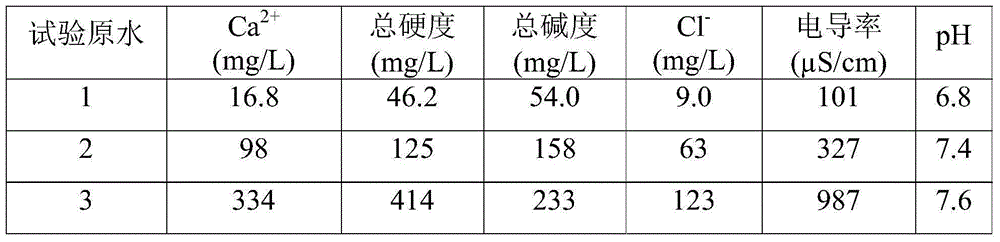

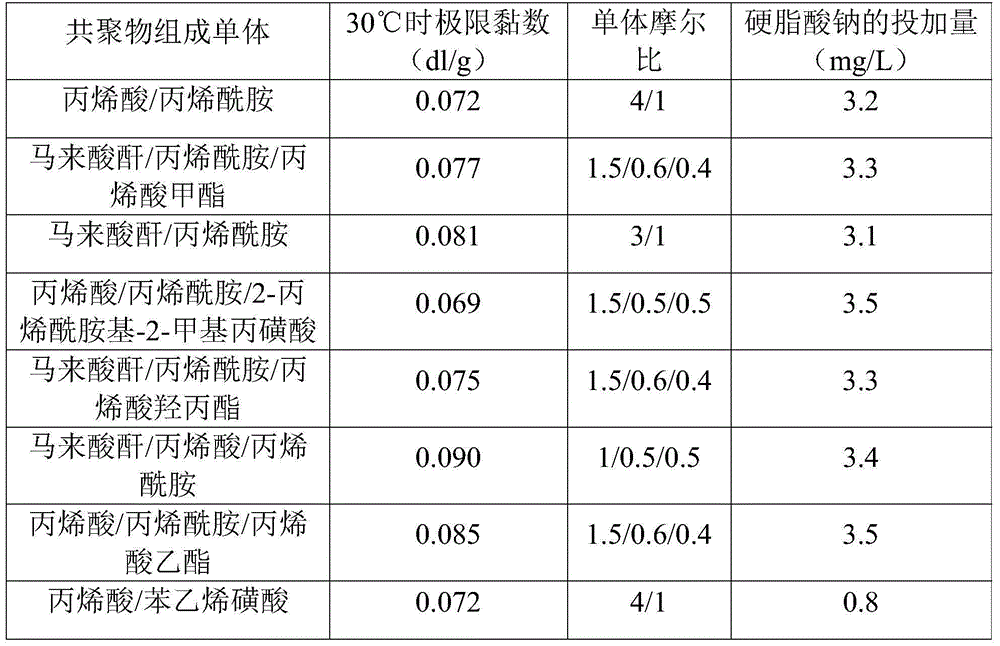

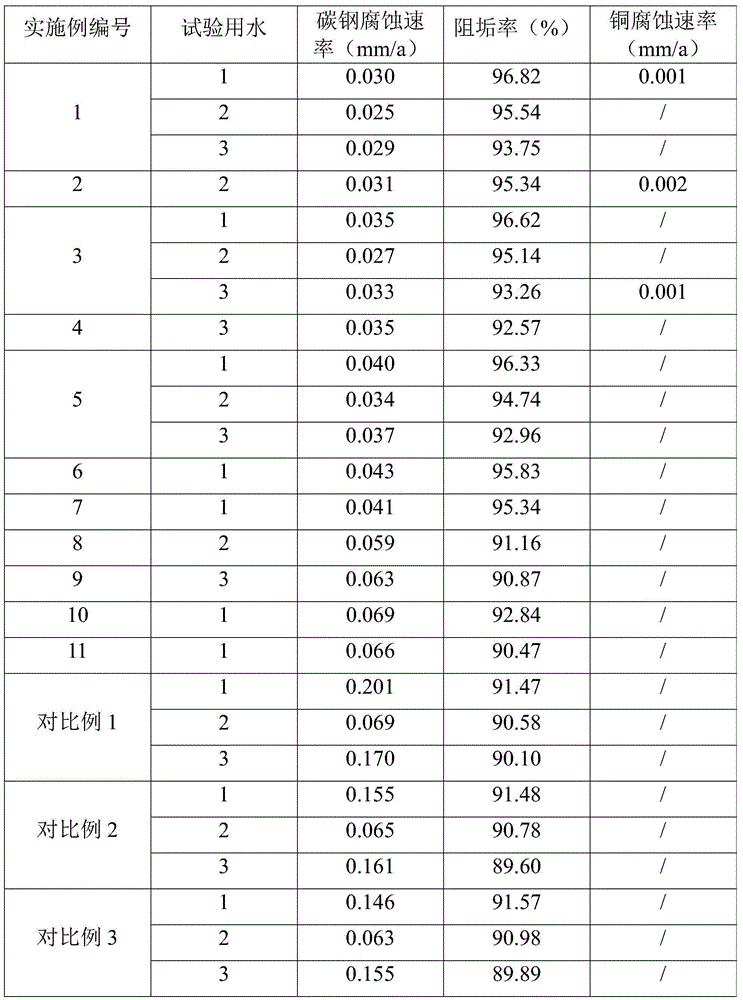

Embodiment 1

[0046] Weigh 2.6g of stearic acid, 66.7g of acrylic acid and acrylamide copolymer with an active substance content of 30% by weight (at 30°C, the limiting viscosity is 0.072dl / g, the molar ratio of acrylic acid to acrylamide=4 / 1), 35g of polyaspartic acid with an active substance content of 40% by weight and 1.7g of zinc sulfate monohydrate were dissolved in 94.1g of water to prepare a corrosion and scale inhibitor. Add the prepared medicament to the test water 1 so that the concentration of the corrosion and scale inhibitor is 100mg / L test water. And add benzotriazole to the test water 1 so that the effective concentration is 1 mg / L test water.

[0047] Weigh 2.6g of stearic acid, 66.7g of acrylic acid and acrylamide copolymer with an active substance content of 30% by weight (at 30°C, the limiting viscosity is 0.072dl / g, the molar ratio of acrylic acid to acrylamide=4 / 1), 35g of polyaspartic acid with an active substance content of 40% by weight was dissolved in 95.7g of wa...

Embodiment 2

[0049] Take by weighing 2.2g sodium stearate, 81.5g active substance content be the maleic anhydride and acrylamide and methyl acrylate copolymer (30 ℃ limit viscosity number is 0.077dl / g, maleic anhydride and acrylamide Molar ratio with methyl acrylate=1.5 / 0.6 / 0.4), 33.3g of polyepoxysuccinic acid with an active substance content of 40% by weight was dissolved in 83g of water to prepare a corrosion and scale inhibitor.

[0050] Add the prepared medicament to the test water 2, so that the concentration of the corrosion and scale inhibitor is 90 mg / L test water. And add mercaptobenzothiazole to the test water 2 so that the effective concentration is 2.0mg / L test water.

Embodiment 3

[0052] Take by weighing 2.7g potassium stearate, 54.6g active substance content be the maleic anhydride and acrylamide copolymer (30 ℃ limit viscosity number is 0.081dl / g, the mol ratio of maleic anhydride and acrylamide = 3 / 1), 48.5g of polyacrylic acid with an active substance content of 30% by weight, and 1.1g of zinc chloride were dissolved in 93.1g of water to prepare a corrosion and scale inhibitor. Add the prepared medicament to the test water 1 so that the concentration of the corrosion and scale inhibitor is 110mg / L test water.

[0053] Take by weighing 2.7g potassium stearate, 54.6g active substance content be the maleic anhydride and acrylamide copolymer (30 ℃ limit viscosity number is 0.081dl / g, the mol ratio of maleic anhydride and acrylamide = 3 / 1), 48.5g of polyacrylic acid with an active substance content of 30% by weight was dissolved in 94.2g of water to prepare a corrosion and scale inhibitor. Add the prepared chemicals to test water 2 and 3 respectively, s...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Limit viscosity | aaaaa | aaaaa |

| Limit viscosity | aaaaa | aaaaa |

| Limit viscosity | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com