Solid corrosion and scale inhibitor and preparation method thereof

A corrosion and scale inhibitor, solid technology, applied in chemical instruments and methods, earthwork drilling, wellbore/well components, etc., can solve the problem of high one-time investment, high maintenance cost, high power consumption, and oil wells that cannot be automated Dosing and other problems to achieve the effect of reducing workload, avoiding maintenance costs, and excellent corrosion and scale inhibition effects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

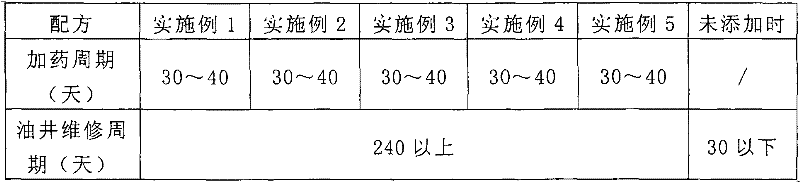

Examples

Embodiment 1

[0027] Each component of solid corrosion and scale inhibitor in the present embodiment is as follows:

[0028] Sodium hydroxyethylidene diphosphonate 5kg

[0029] Trisodium Phosphate 25kg

[0030] Zinc Chloride 20kg

[0031] Octadecyl primary amine 5 kg

[0032] Starch 5 kg

[0033] Sodium citrate 8 kg.

[0034] The steps of the preparation method are:

[0035] (1) Add the above materials into the mixer and mix thoroughly;

[0036] (2) The mixed material is dried at 50°C, and the dried material is placed in a dry place for subsequent use;

[0037] (3) Add the dried material to the granulator, and carry out granulation under normal temperature conditions;

[0038] (4) The material after the granulation is completed is sent to the tablet press immediately, and is compressed at normal temperature and under a pressure of 4 tons;

[0039] (5) The tablet after tablet compression is directly packaged to obtain the finished solid corrosion and scale inhibitor.

Embodiment 2

[0041] Each component of solid corrosion and scale inhibitor in the present embodiment is as follows:

[0042] Sodium Amino Trimethylene Phosphonate 15kg

[0043] Sodium tripolyphosphate 40 kg

[0044] Zinc Chloride 30kg

[0045] Tallow diamine 10 kg

[0046] Starch 10 kg

[0047] Sodium citrate 12 kg.

[0048] The steps of the preparation method are:

[0049] (1) Add the above materials into the mixer and mix thoroughly;

[0050] (2) The mixed material is dried at 80°C, and the dried material is placed in a dry place for subsequent use;

[0051] (3) Add the dried material to the granulator, and carry out granulation under normal temperature conditions;

[0052] (4) The material after the granulation is completed is sent to the tablet press immediately, and is pressed at normal temperature and under a pressure of 12 tons;

[0053] (5) The tablet after tablet compression is directly packaged to obtain the finished solid corrosion and scale inhibitor.

Embodiment 3

[0055] Each component of solid corrosion and scale inhibitor in the present embodiment is as follows:

[0056] Sodium hydroxyethylidene diphosphonate 10 kg

[0057] Sodium hexametaphosphate 30kg

[0058] Zinc Chloride 25kg

[0059] Tallow diamine 8 kg

[0060] Starch 8 kg

[0061] Sodium citrate 10 kg.

[0062] The steps of the preparation method are:

[0063] (1) Add the above materials into the mixer and mix thoroughly;

[0064] (2) The mixed material is dried at 60°C, and the dried material is placed in a dry place for subsequent use;

[0065] (3) Add the dried material to the granulator, and carry out granulation under normal temperature conditions;

[0066] (4) The material after the granulation is completed is sent to the tablet press immediately, and is compressed at normal temperature and under a pressure of 8 tons;

[0067] (5) The tablet after tablet compression is directly packaged to obtain the finished solid corrosion and scale inhibitor.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com