Corrosion and scale inhibitor specially used for circulating water system in oxygen production plant and preparation method thereof

A corrosion and scale inhibitor, circulating water system technology, applied in chemical instruments and methods, descaling and water softening, water/sludge/sewage treatment, etc., can solve the problems affecting the normal production and production safety of the oxygen generation system The problem of increased pressure difference between the inlet and outlet of the tower, molecular sieve water inflow, etc., achieves the effect of obvious synergistic effect of scale inhibition, good adsorption performance, and good degradability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

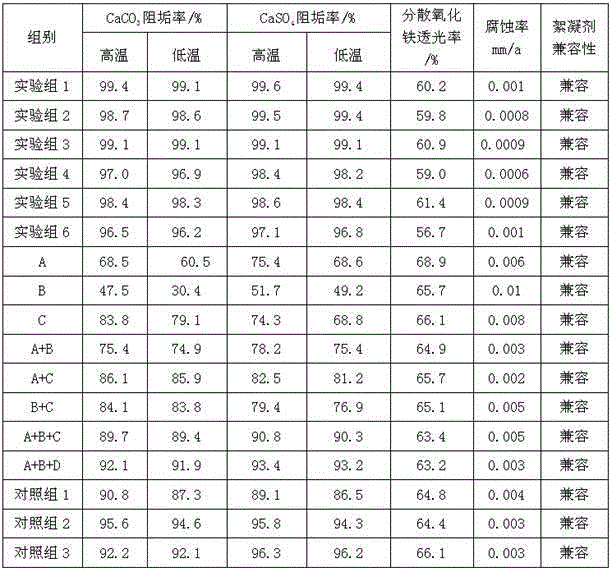

Examples

Embodiment 1

[0046] The corrosion and scale inhibitor for the circulating water system of the oxygen plant in this embodiment includes the following components in mass percentage:

[0047] Methylsulfonate polyepoxysuccinic acid 30%,

[0048] Acrylic acid-methyl acrylate-acrylamide-AMPS copolymer 22%,

[0049] Maleic-Acrylic Copolymer 16%,

[0050] Graphene oxide aqueous dispersion 4%,

[0051] Fatty alcohol polyoxyethylene ether 5%,

[0052] BTA aqueous solution 23%,

[0053] The mass fraction of the BTA aqueous solution is 12%.

[0054] The preparation method of the corrosion and scale inhibitor for the circulating water system of the oxygen plant in this embodiment is as follows:

[0055] Weigh sulfonate methylamino polyepoxysuccinic acid, acrylic acid-methyl acrylate-acrylamide-AMPS copolymer, maleic acid-acrylic acid copolymer and graphene oxide aqueous dispersion in proportion, add them to the container in turn, mix , heated to 90°C, added BTA a...

Embodiment 2

[0057] The corrosion and scale inhibitor for the circulating water system of the oxygen plant in this embodiment includes the following components in mass percentage:

[0058] Sulfonated methylamino polyepoxysuccinic acid 25%,

[0059] Acrylic acid-methyl acrylate-acrylamide-AMPS copolymer 20%,

[0060] Maleic-acrylic acid copolymer 12%,

[0061] Graphene oxide aqueous dispersion 3%,

[0062] Fatty alcohol polyoxyethylene ether 3%,

[0063] BTA aqueous solution 37%,

[0064] The mass fraction of the BTA aqueous solution is 12%.

[0065] The preparation method of the corrosion and scale inhibitor for the circulating water system of the oxygen plant in this embodiment is as follows:

[0066] Weigh sulfonate methylamino polyepoxysuccinic acid, acrylic acid-methyl acrylate-acrylamide-AMPS copolymer, maleic acid-acrylic acid copolymer and graphene oxide aqueous dispersion in proportion, add them to the container in turn, mix , heated to...

Embodiment 3

[0068] The corrosion and scale inhibitor for the circulating water system of the oxygen plant in this embodiment includes the following components in mass percentage:

[0069] Methylsulfonate polyepoxysuccinic acid 40%,

[0070] Acrylic acid-methyl acrylate-acrylamide-AMPS copolymer 22%,

[0071] Maleic-acrylic acid copolymer 15%,

[0072] Graphene oxide aqueous dispersion 4%,

[0073] Fatty alcohol ethoxylates 4%,

[0074] BTA aqueous solution 15%.

[0075] The mass fraction of the BTA aqueous solution is 12%.

[0076] The preparation method of the corrosion and scale inhibitor for the circulating water system of the oxygen plant in this embodiment is as follows:

[0077] Weigh sulfonate methylamino polyepoxysuccinic acid, acrylic acid-methyl acrylate-acrylamide-AMPS copolymer, maleic acid-acrylic acid copolymer and graphene oxide aqueous dispersion in proportion, add them to the container in turn, mix , heated to 65°C, added BTA ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| concentration | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

| hardness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com