High-hardness, wear-resistant and corrosion-resistant alloy of amorphous/nanocrystal matrix and preparation method of high-hardness, wear-resistant and corrosion-resistant alloy

A corrosion-resistant alloy and nanocrystalline technology, applied in the preparation of wear-resistant and corrosion-resistant cast iron alloys and their components, and the manufacture of mechanical wear-resistant parts, can solve the problems of low alloy toughness, limited application scope, and difficulty in application, and achieve casting. Simple process requirements, good fluidity and low melting point

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

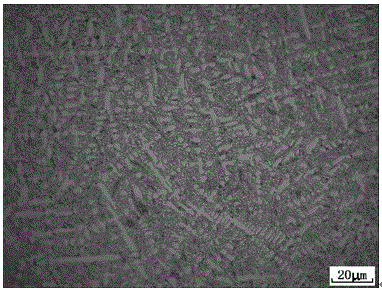

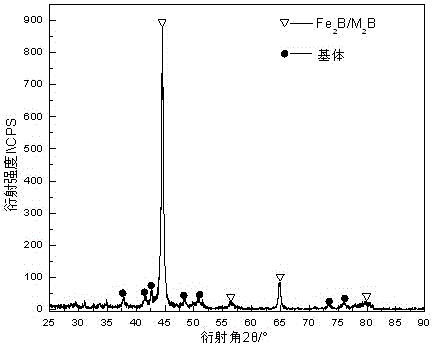

[0031] Embodiment 1. Select high-carbon ferrochrome, microcarbon ferrochrome, ferroboron, ferro-niobium, ferro-vanadium and industrial pure iron as raw materials, and the composition range is as follows: Cr: 10.0wt.%; B: 2.9wt.%; C: 0.7wt.%; Nb: 0.4wt.%; V: 0.2wt.%; See Table 2 for the control of impurity elements. Induction melting and iron mold casting are adopted, the melting temperature is 1500°C, and the casting temperature is about 1400°C. When the temperature of the ingot is about 800°C, the iron mold is opened and air-cooled. The ingot weighs 40kg and the thickness is 30mm.

Embodiment 2

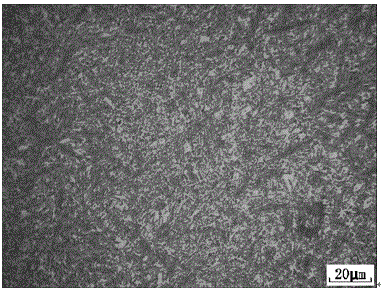

[0032] Embodiment 2. Select high-carbon ferrochrome, metal chromium, ferroboron, ferroniobium and industrial pure iron as raw materials, and the composition range is as follows: Cr: 10.0wt.%; B: 2.7wt.%; C: 0.7wt.%; Nb: 0.5wt.%; see Table 2 for the control of impurity elements. Induction melting and sand casting are used to cast the master alloy into strips, the melting temperature is 1450°C, and the casting temperature is about 1400°C. Remelt the master alloy cast strips with a resistance furnace, the melting temperature is about 1300°C, and use a die-casting machine to die-cast them into precision parts. The weight of a single part is 300g, and the minimum thickness is 2mm.

Embodiment 3

[0033] Embodiment 3. select high-carbon ferrochrome, micro-carbon ferrochrome, ferroboron, ferro-niobium and industrial pure iron as raw materials, the composition range is as follows: Cr: 10.0wt.%; B: 2.7wt.%; C: 0.8wt.% %; Nb: 0.6wt.%; See Table 2 for the control of impurity elements. Induction melting and centrifugal iron mold casting are adopted, the melting temperature is 1500°C, and the casting temperature is about 1400°C. When the temperature of the ingot is about 800°C, the iron mold is opened and air-cooled. The ingot weighs 120kg and the thickness is 30mm.

PUM

| Property | Measurement | Unit |

|---|---|---|

| hardness | aaaaa | aaaaa |

| hardness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com