Plating solution for continuous hot dipping of steel strips and dipping method thereof

A technology of hot-dip plating and plating solution, applied in hot-dip plating process, coating, metal material coating process, etc., can solve the problems of poor mechanical properties, poor wettability, and prone to missing plating, etc., and achieve improved corrosion resistance Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0017] In the present invention, unless otherwise specified, the percentages used are all percentages by mass. It should be noted that operations that are not described in detail in the present invention are all prior art in the art, and will not be repeated here.

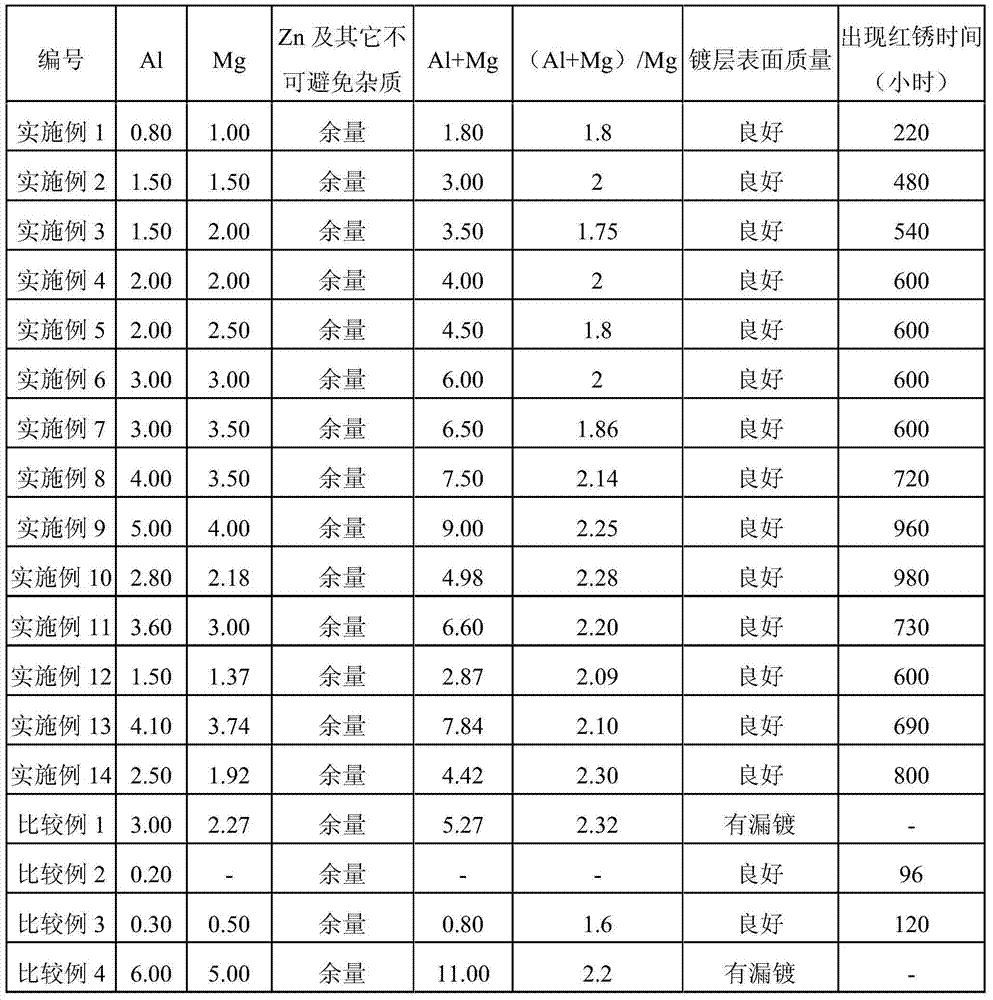

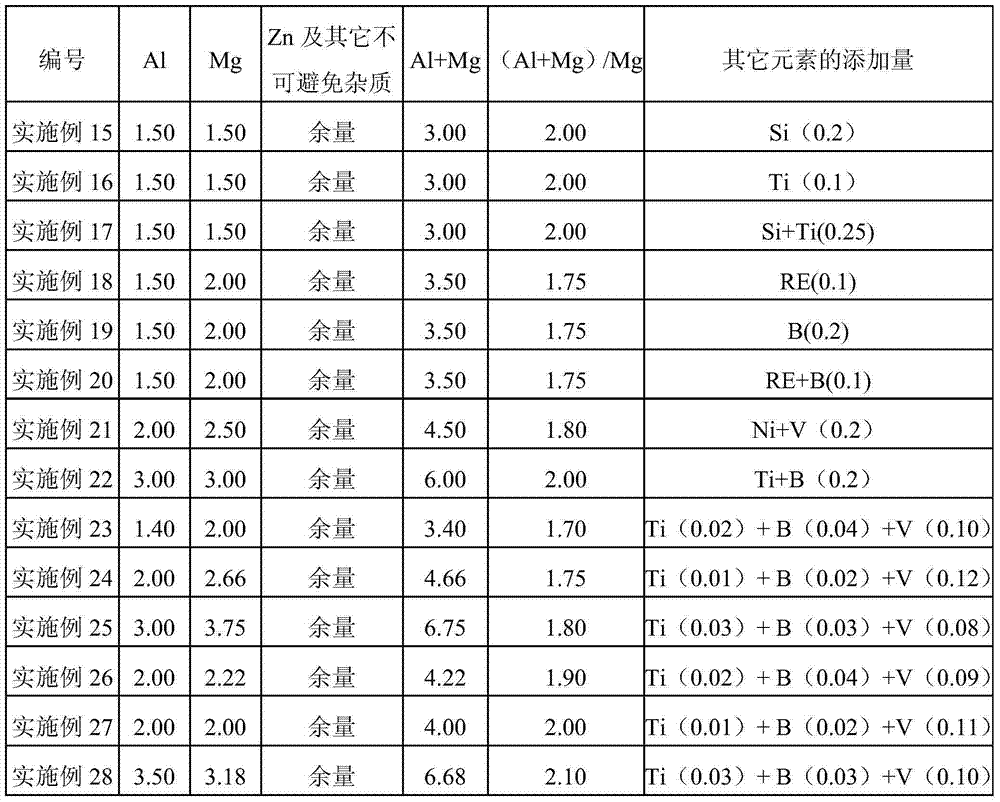

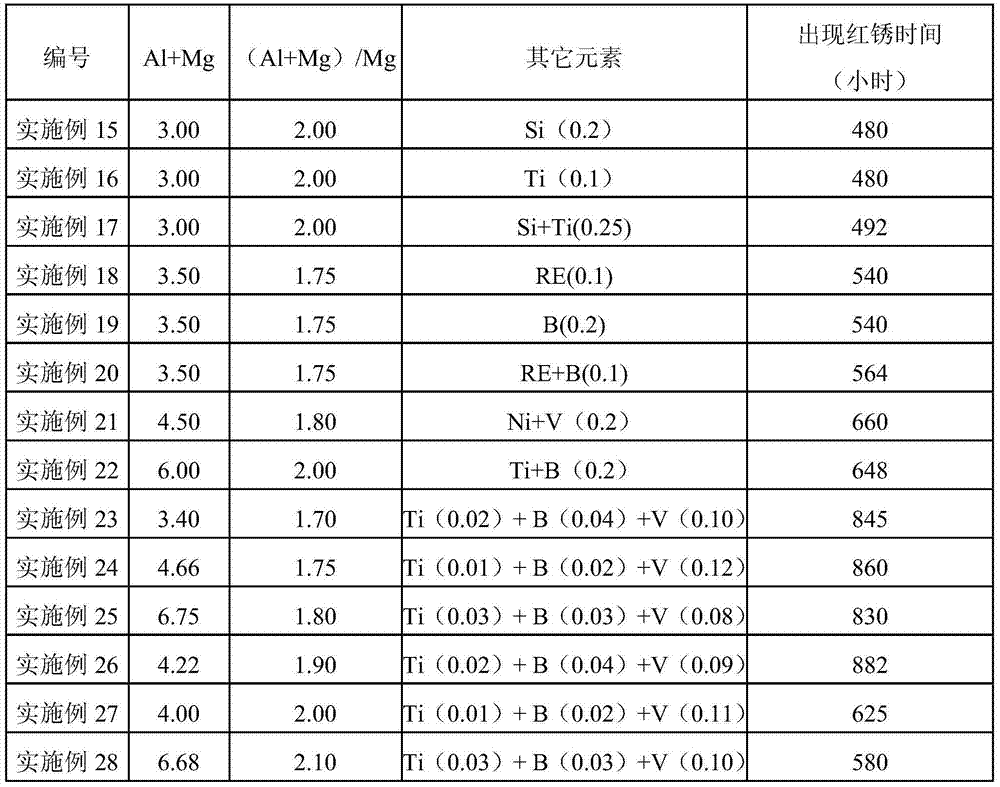

[0018] The plating solution for continuous hot-dipping steel strip of the present invention comprises: Al: 0.5-5 mass %, Mg: 1-4 mass %, the balance is Zn and unavoidable impurity, wherein, the content of Al and Mg satisfies The following conditions: (Al+Mg) is 1.5-9% by mass, (Al+Mg) / Mg is 1.70-2.30.

[0019] Using the above-mentioned plating solution, the corrosion resistance of the plating layer can be improved jointly through the joint action of Al and Mg. The ratio of Al and Mg content in the plating solution also has a significant impact on the quality of the coating. The structure of zinc-aluminum-magnesium alloy coating is mainly composed of: Zn-rich phase, Al-rich phase, binary eutectic phase, Zn-Al-MgZn...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com