Corrosion-resistant and high-strength and toughness Zn-Fe-Li-based zinc alloy capable of being degraded in human body and application of corrosion-resistant and high-strength and toughness Zn-Fe-Li-based zinc alloy

A zinc alloy, zn-fe-li technology, applied in medical science, surgery, surgical instruments, etc., can solve the problems of inability to provide mechanical support time, low plasticity of zinc alloy materials, uncontrollable degradation rate, etc. control, grain refinement, good strength and toughness

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

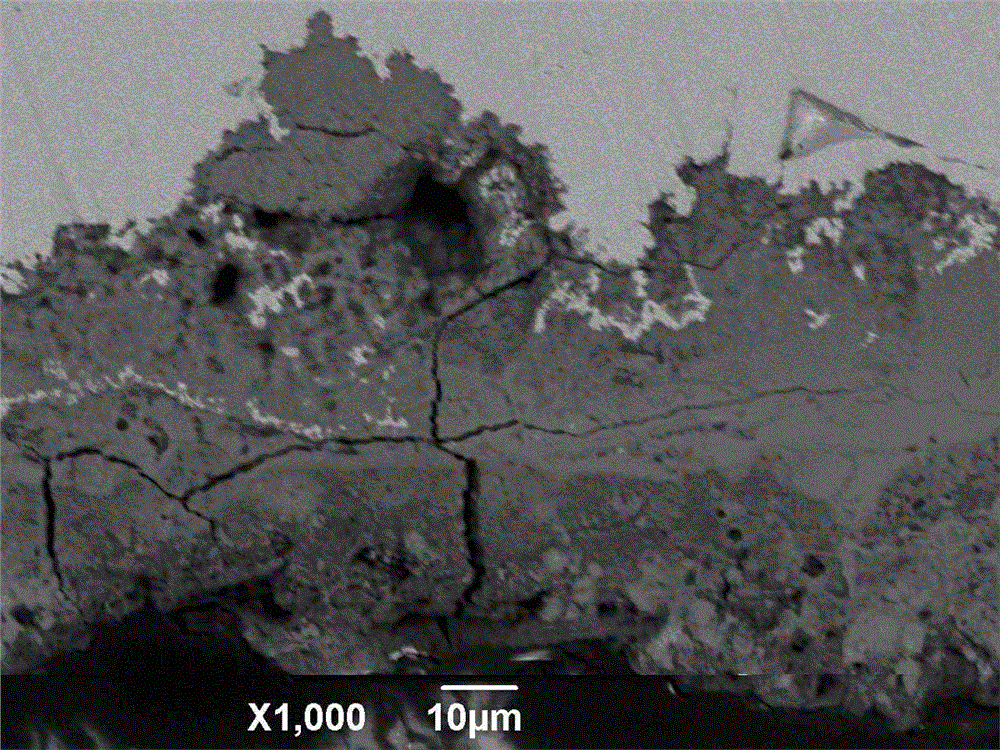

Image

Examples

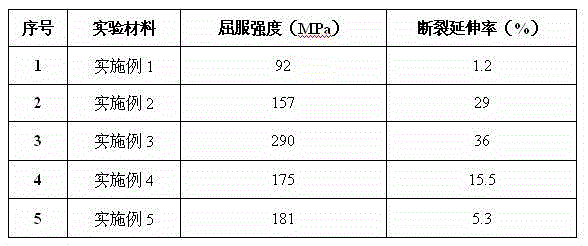

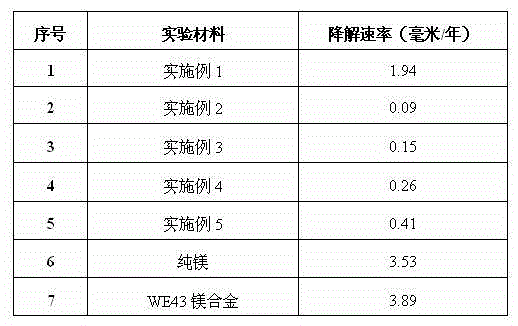

Embodiment 1

[0023] A human body degradable corrosion-resistant high-strength Zn-Fe-Li zinc alloy of the present invention has an elemental composition and mass percentage of: Zn 80%, Fe 10%, Li 10%.

Embodiment 2

[0025] A human body degradable corrosion-resistant high-strength Zn-Fe-Li zinc alloy of the present invention has the following element composition and mass percentage: Zn 99.997%, Fe 0.002%, Li 0.001%.

Embodiment 3

[0027] A human body degradable corrosion-resistant high-strength Zn-Fe-Li zinc alloy of the present invention has the following element composition and mass percentage: Zn 99.975%, Fe 0.01%, Li 0.015%.

PUM

| Property | Measurement | Unit |

|---|---|---|

| Yield strength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com