Water-phase electrolyte system zinc iodine secondary battery and preparation method thereof

A secondary battery and electrolyte technology, which is applied in the field of energy storage, can solve the problems of zinc-iodine batteries, such as few reports, and achieve the effects of high iodine loading, mild conditions, and low self-discharge rate

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0021] 2g of mesoporous carbon material and 2g of elemental iodine are sealed in a container, heated to 40°C and kept for 10 minutes to obtain a composite, and the obtained composite is heated to 120°C and kept for 2 hours to finally obtain an iodine / mesoporous carbon composite . Grind the iodine / mesoporous carbon composite, acetylene black, and sodium carboxymethylcellulose uniformly at a mass ratio of 8:1:1 to obtain a mixture. Water was added to the mixture and stirred to obtain a slurry, which was spread onto aluminum foil. After being completely dried under the condition of 80° C. in a vacuum environment, the positive electrode of the battery is obtained. A Zamak3 alloy with a thickness of 0.2 mm was taken, mechanically polished and cleaned to obtain a battery negative electrode. Prepare a zinc nitrate aqueous solution with a concentration of 2 mol / liter as the electrolyte. A 2032-type button cell was assembled with glass fiber as a separator.

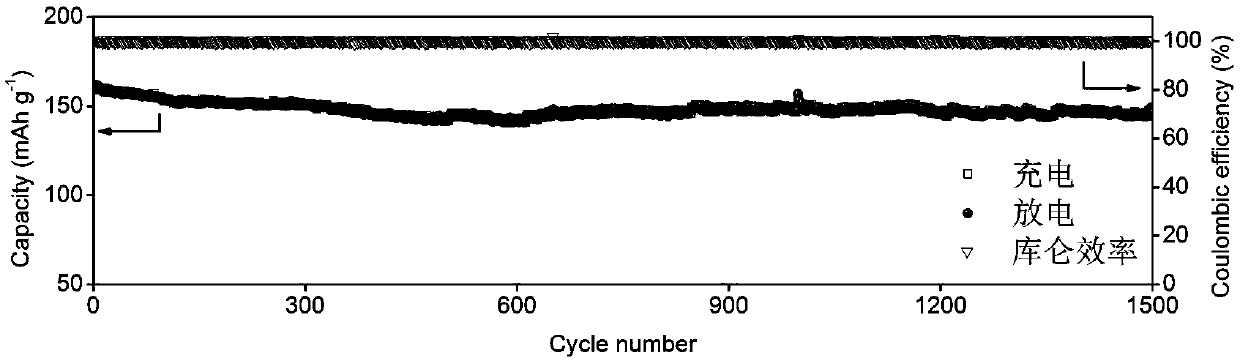

[0022] figure 1 It is...

Embodiment 2

[0024] 3g of activated carbon fibers and 2g of elemental iodine are sealed in a container, heated to 60°C and kept for 25 minutes to obtain a composite. The resulting composite was heated to 150° C. and kept for 4 hours to finally obtain an iodine / activated carbon fiber composite. The iodine / activated carbon fiber composite, Ketjen black and polytetrafluoroethylene are ball milled uniformly at a mass ratio of 7:2:1 to obtain a mixture. Water was added to the mixture and stirred evenly to obtain a slurry, which was coated onto stainless steel foil. After being completely dried under the condition of 80° C. in a vacuum environment, the positive electrode of the battery is obtained. The high-purity zinc foil with a thickness of 0.1 mm was manually polished and cleaned to obtain the negative electrode material. Use qualitative filter paper as the diaphragm. Prepare an aqueous zinc sulfate solution with a concentration of 1 mol / L as the electrolyte. A positive electrode materia...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Discharge capacity | aaaaa | aaaaa |

| Thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com