Three-dimensional current collector for metal secondary battery anode and preparation and application thereof

A secondary battery and current collector technology, applied in the field of electrochemical power sources, can solve the problems of unbearable volume change, unstable interface contact, poor kinetic behavior, etc., and achieve suitable for large-scale production, large electroactive surface area, and high practicality sexual effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

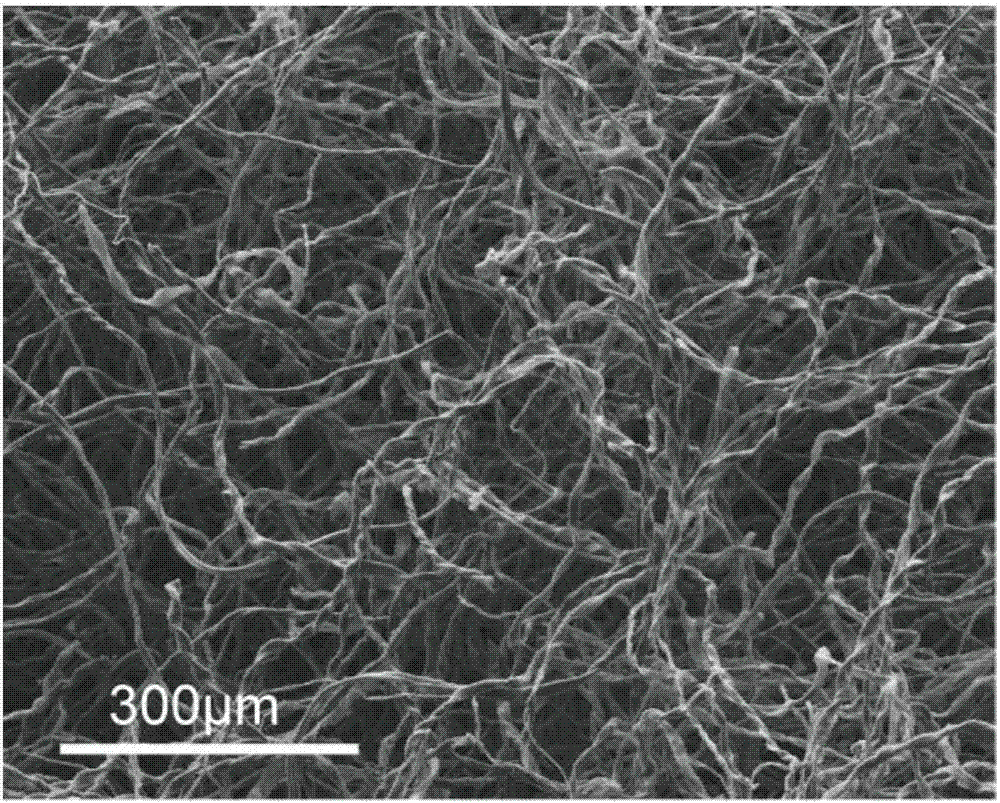

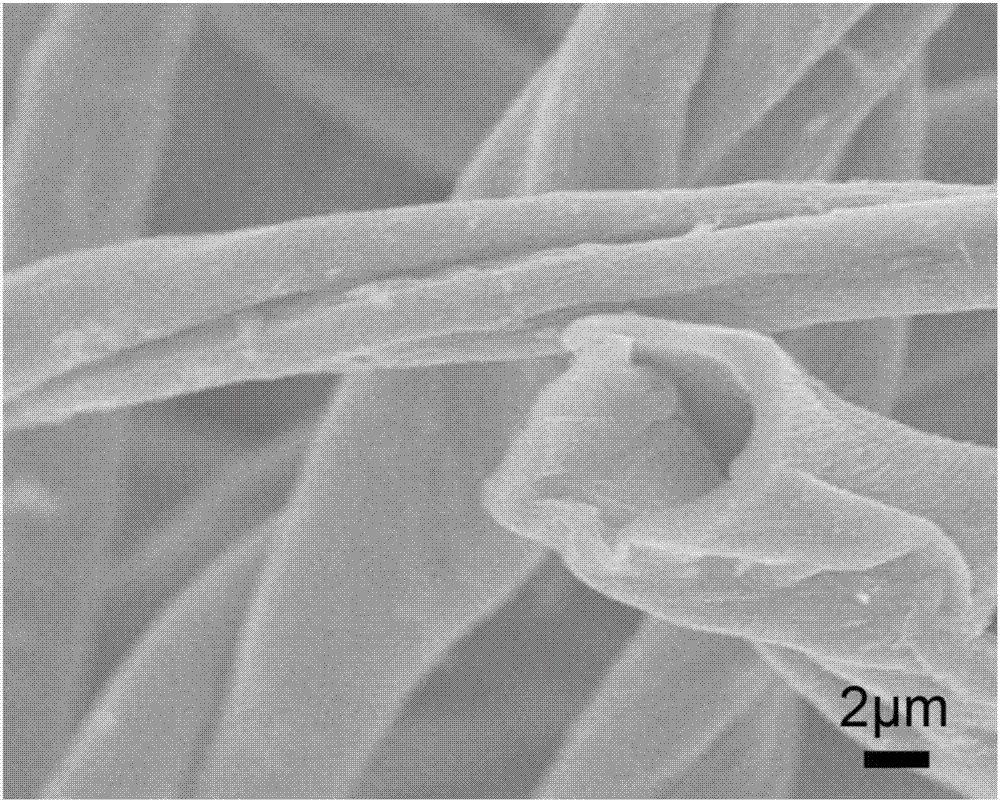

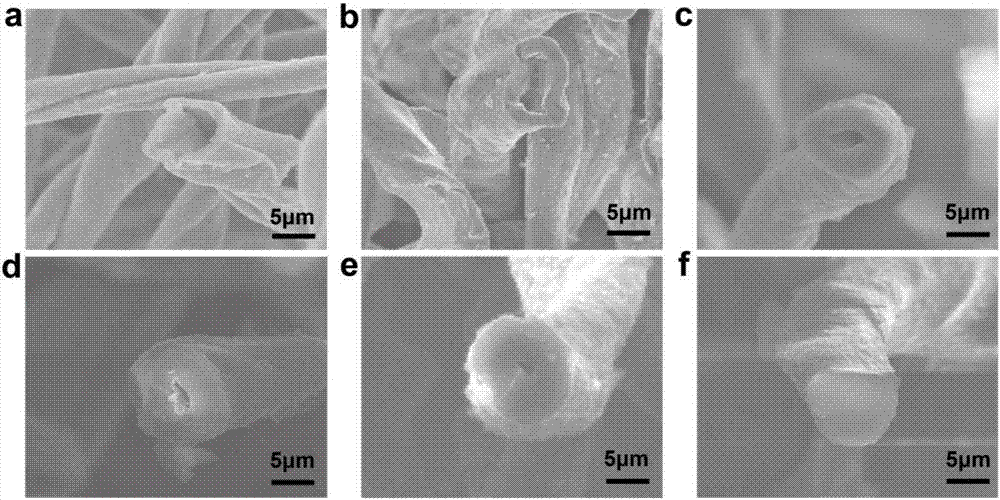

[0039] (1) Preparation of three-dimensional porous hollow carbon fiber

[0040] The biomass raw material cotton is repeatedly washed 3 times with ethanol and deionized water, dried, rolled, sliced, and calcined in a tube furnace at 1200°C in an inert atmosphere nitrogen at a heating rate of 2°C / min, sintered for 3 hours, biomass The raw material is carbonized into hollow carbon fiber. After the carbonization is completed, the heating is stopped, the protection gas is maintained, the reactor is cooled to room temperature, and the sample is taken out. The result is a three-dimensional porous hollow carbon fiber. Then use 1M activating reagent KOH to soak the ultrasonic sample for 5h, dry it, and calcinate it for 2h at 800°C and 5°C / min heating rate in nitrogen atmosphere. After the activation, the sample after activation is taken out, washed with dilute hydrochloric acid, and then repeatedly washed with deionized water and ethanol for several times, and dried to obtain the desired...

Embodiment 2

[0053] The only difference from Example 1 is (1) The three-dimensional porous hollow carbon fiber current collector is prepared, and the carbonization temperature used is 800°C. The three-dimensional porous hollow carbon fiber current collector is formed by intertwining micron carbon fibers with a pore volume per unit area of 0.01 cm 3 cm -2 , The diameter of the micron carbon fiber is about 25μm, and the micron carbon fiber has a hollow structure with a wall thickness of 5μm.

[0054] Deposit 4mA h cm -2 After lithium, the deposition / stripping efficiency of lithium was 80% for the first time and reached 97% after 10 cycles. The three-dimensional porous hollow carbon fiber current collector load 18 mA h cm -2 In the case of metallic lithium, no lithium dendrites were formed after 10 cycles.

Embodiment 3

[0056] The only difference from Example 1 is (1) The three-dimensional porous hollow carbon fiber current collector is prepared, and the calcination temperature used is 1000°C. The three-dimensional porous hollow carbon fiber current collector is formed by intertwining micrometer carbon fibers, and the pore volume per unit area is 0.015 cm 3 cm -2 , The diameter of the micron carbon fiber is about 15μm, and the micron carbon fiber has a hollow structure with a wall thickness of 2μm.

[0057] Deposit 4mA h cm -2 After lithium, the deposition / stripping efficiency of lithium was 87% for the first time and reached 98% after 10 cycles. The three-dimensional porous hollow carbon fiber current collector load 18 mA h cm -2 In the case of metallic lithium, no lithium dendrites were formed after 10 cycles.

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com