Stainless steel wire with flux core for welding zinc coated steel sheets

A technology of stainless steel wire and stainless steel, which is applied in the direction of welding/cutting medium/material, welding medium, welding equipment, etc., and can solve problems such as preventing zinc embrittlement cracks from being unstable

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

example

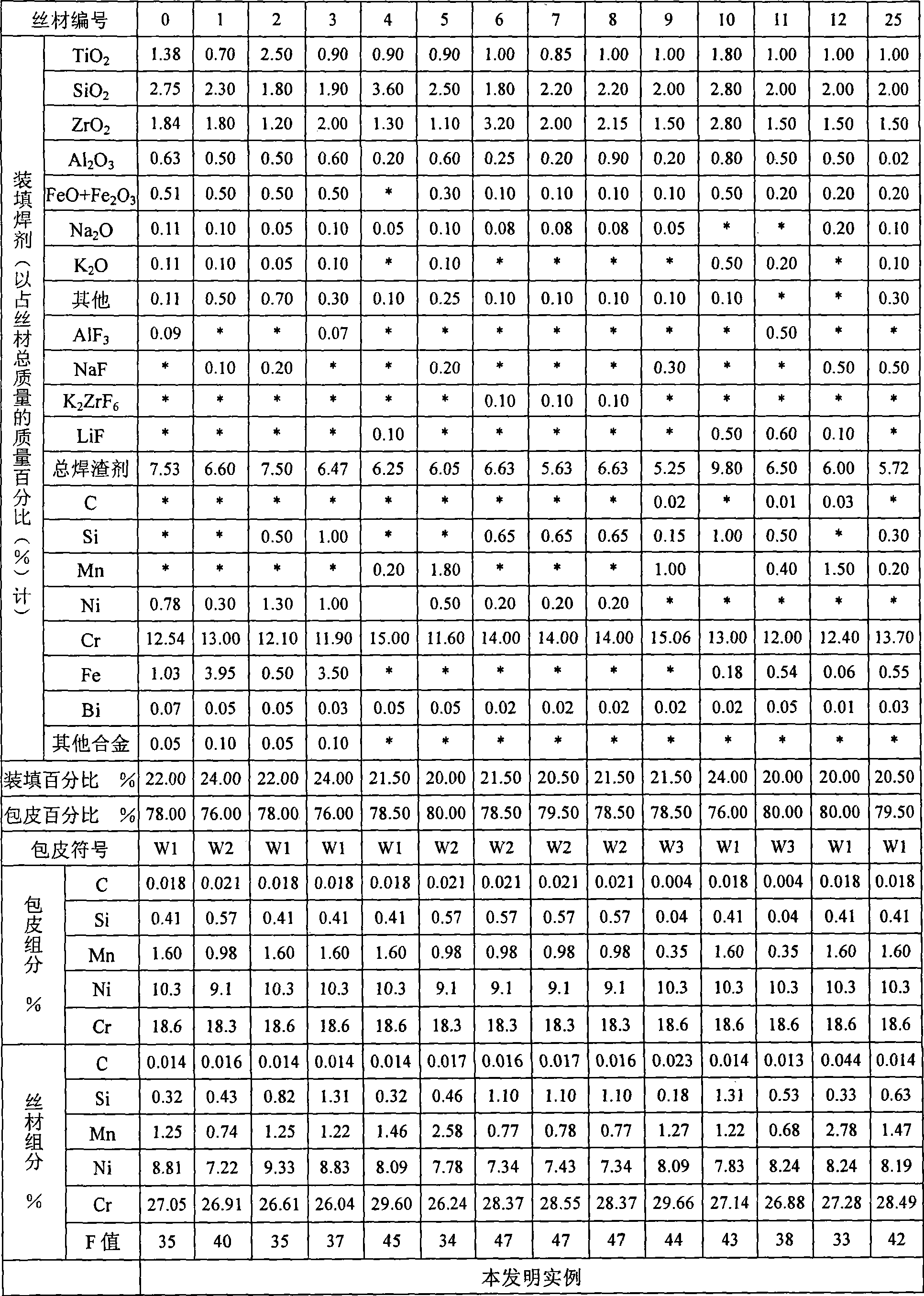

[0083] All concentrations are mass percent based on the total mass of the filament unless otherwise stated. Samples of flux-cored wire for welding zinc-based alloy-coated steel sheets had the compositions shown in Tables 2 and 3. Table 1 shows the chemical composition of the outer metal sheath of the austenitic-based stainless steel.

[0084] Table 1

[0085] symbol C Si mn P S Ni Cr Mo N O W1 0.018 0.41 1.60 0.022 0.002 10.3 18.6 0.04 0.02 0.006 W2 0.021 0.57 0.98 0.027 0.005 9.1 18.3 0.16 0.05 0.004 W3 0.004 0.04 0.35 0.025 0.001 9.5 18.0 0.50 0.03 0.005

[0086] Table 2

[0087] * Indicates the impurity level

[0088]

[0089] table 3

[0090] * Indicates the impurity level

[0091]

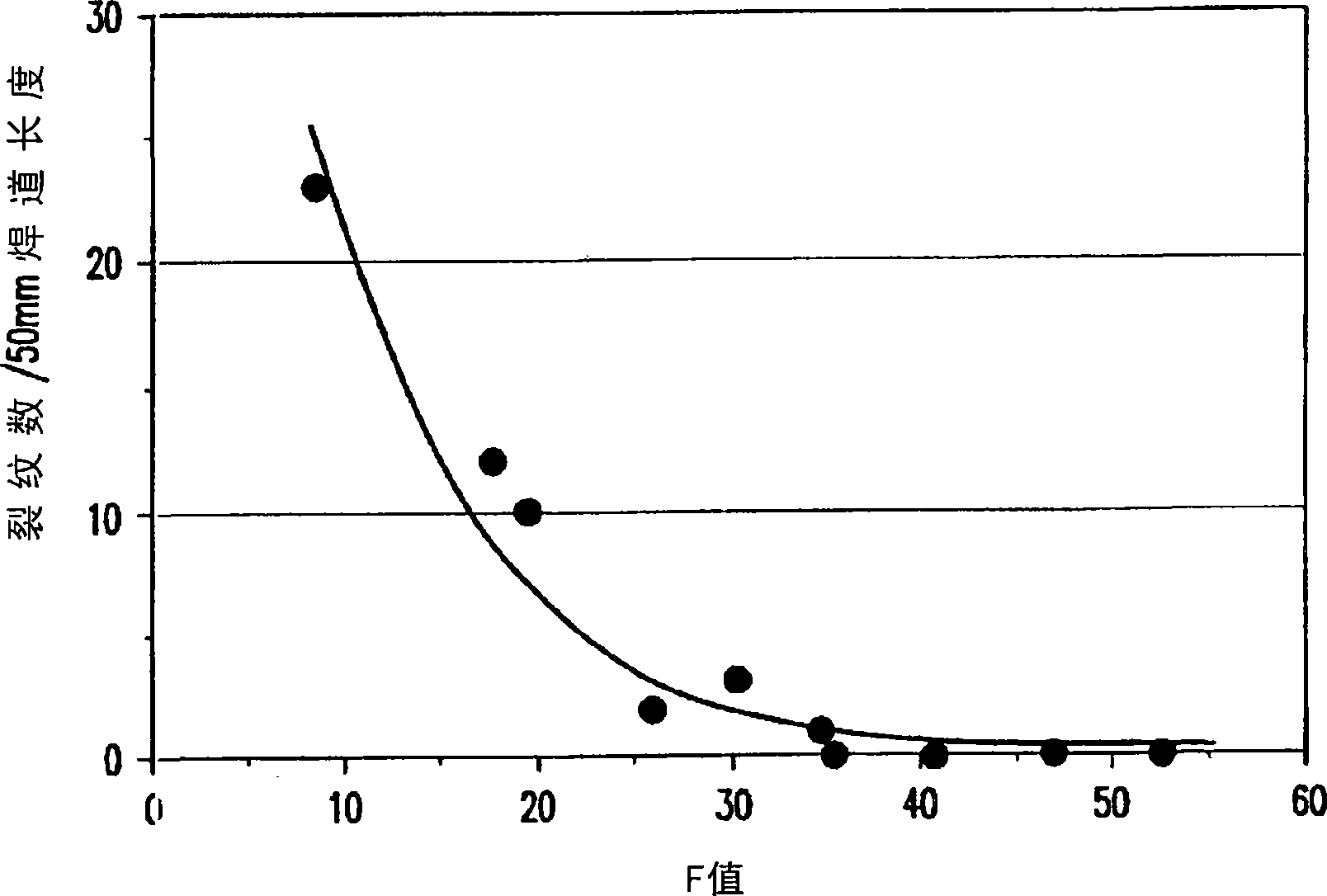

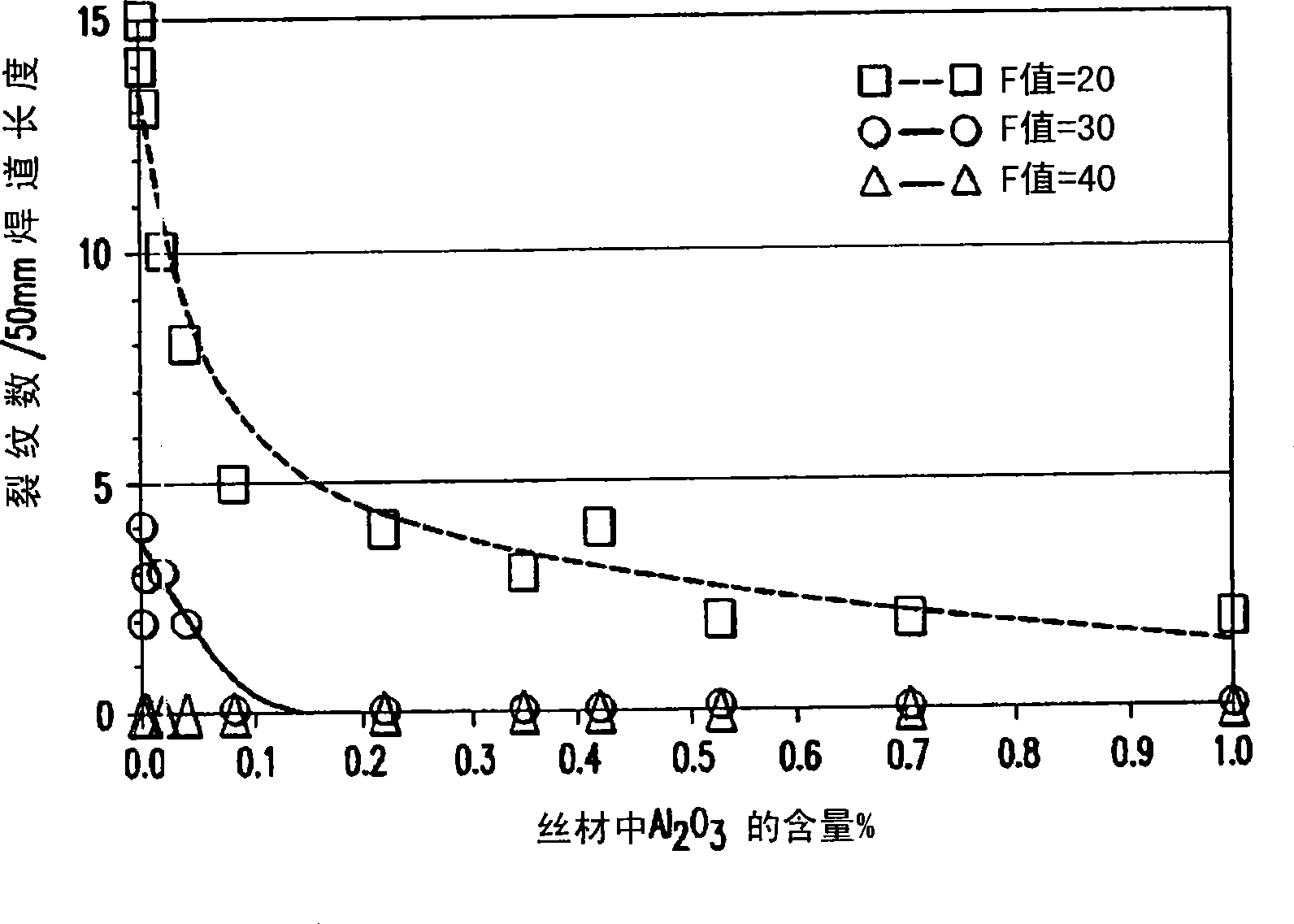

[0092] As for the properties of the deposited metal (plated metal), a tensile test was performed according to JIS Z 3323. The impact test was performed according to JIS Z 3111. In the inspection of welded join...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com