Degradable corrosion-resistant high-toughness Zn-Fe zinc alloy for human body and application thereof

A zinc alloy and corrosion-resistant technology, applied in the field of corrosion-resistant, high-strength and tough Zn-Fe zinc alloys, can solve the problems of inability to provide mechanical support time, low plasticity of zinc alloy materials, uncontrollable degradation rate, etc., and achieve controllable degradation rate , fine grain, good strength and toughness

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

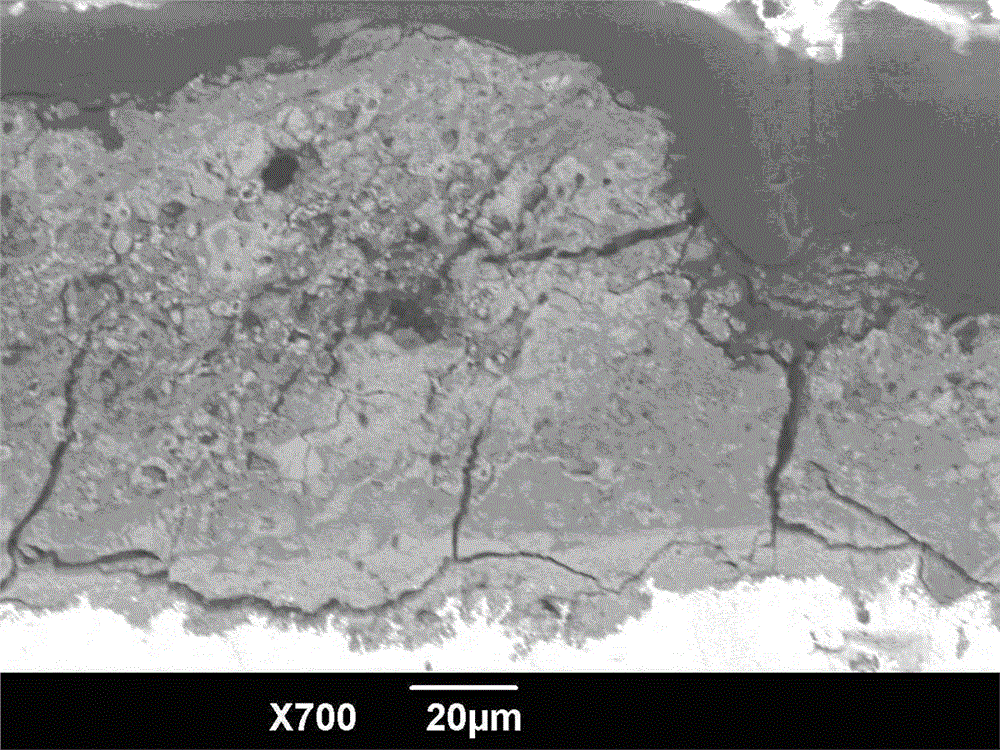

Image

Examples

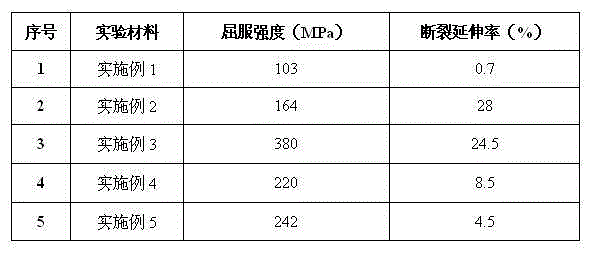

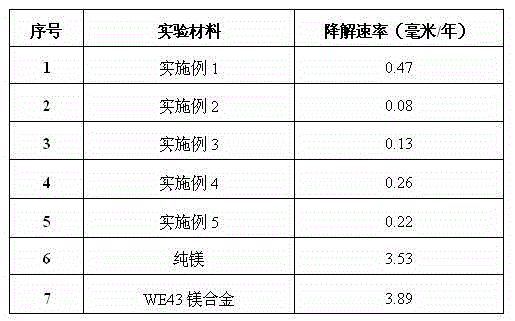

Embodiment 1

[0023] A human body degradable corrosion-resistant high-strength Zn-Fe zinc alloy of the present invention has the following element composition and mass percentage: Zn 90%, Fe 10%.

Embodiment 2

[0025] A human body degradable corrosion-resistant high-strength Zn-Fe zinc alloy of the present invention has the following element composition and mass percentage: Zn 99.998%, Fe 0.002%.

Embodiment 3

[0027] A human body degradable corrosion-resistant high-strength Zn-Fe zinc alloy of the present invention has the following element composition and mass percentage: Zn 99.975%, Fe 0.01%, Mg 0.015%.

PUM

| Property | Measurement | Unit |

|---|---|---|

| yield strength | aaaaa | aaaaa |

| elongation at break | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com