Medical degradable implantable metal material

A metal material and implantable technology, applied in medical science, surgery, prosthesis, etc., can solve the problems of restricting wide application, low strength of pure zinc, and poor plasticity of alloys, so as to reduce infection, improve plasticity and creep resistance The effect of variable performance and good mechanical properties

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0023] The following examples of the present invention are given to further illustrate the present invention, but not to limit the scope of the present invention.

[0024] The specific implementation is as follows:

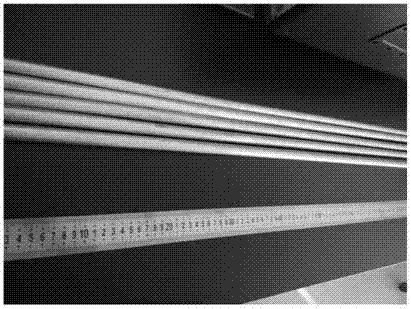

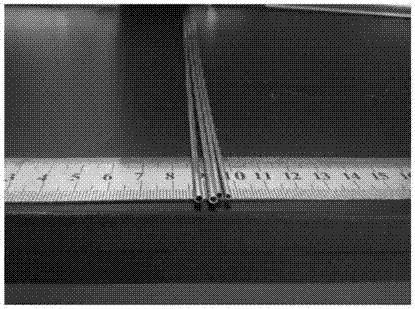

[0025] Choose pure zinc (purity 99.99%), pure magnesium (purity 99.99%), pure manganese (purity 99.7%), Zn-Cu alloy, Zn-Ti alloy as raw materials for equipment, and then use a vacuum induction melting furnace to Melted and cast in a 6 kg high-purity graphite crucible to obtain a 5-alloy ingot, the specific chemical composition of which is shown in Table 1 after being detected by ICP-AES.

[0026] Table 1 The chemical composition of the medical degradable implantable metal material implemented by the present invention

[0027] Zinc alloy

Cu

Ti

Mg

mn

Ag

Zn

1

1.04

0.12

0.09

0.10

0.10

margin

2

1.06

0.30

0.11

0.13

0.11

margin

3

1.53

0.10

0.13

0.09

...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com