Preparing method of fluorescence hollow silicon dioxide microsphere

A silica, hollow technology, applied in the preparation of microspheres, chemical instruments and methods, oxime preparation, etc., can solve the problems of unsuitable hypochlorite, difficult to obtain reagents, long analysis process, etc., to achieve excellent non-toxic and biological Compatibility, Low Detection Limits, and Short Analysis Time Effects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

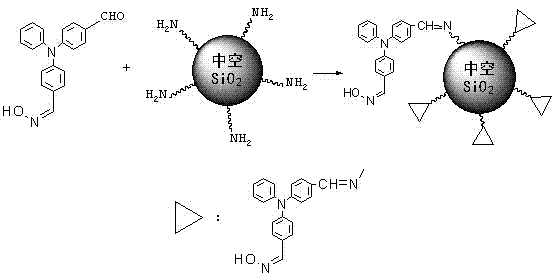

[0032] (1) Preparation of hollow silica microspheres

[0033] Add 0.3g of polyacrylic acid to 4.5ml of ammonia water and mix it with 90ml of absolute ethanol, then divide 1.8ml of tetraethyl orthosilicate 5 times on average, each interval of 1h, add it to the mixed solution, and react under magnetic stirring 10h, then carry out two times of centrifugation and washing with absolute ethanol and deionized water respectively, and make hollow silica microspheres after drying;

[0034] (2) Preparation of amino-modified hollow silica microspheres

[0035] Add 1g of hollow silica microspheres into a three-necked flask, add 50ml of ethanol and 50ml of distilled water to mix, after a period of ultrasonication, add 5ml of γ-aminopropyltriethoxysilane, heat at 85°C for 20 hours, centrifuge and wash , drying to obtain amino-modified hollow silica microspheres;

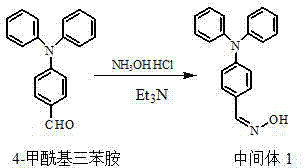

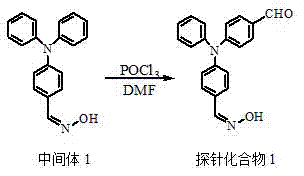

[0036] (3) Preparation of intermediate 1

[0037] Add 0.5g of 4-formyltriphenylamine, 0.19g of hydroxylamine hydrochloride, an...

Embodiment 2

[0043] (1) Preparation of hollow silica microspheres

[0044] Add 0.3g of polyacrylic acid into 4.5ml of ammonia water and mix it with 90ml of absolute ethanol, then divide 2.0ml of tetraethyl orthosilicate into the mixed solution five times with an interval of 1 hour, and react under magnetic stirring 15h, then carry out two times of centrifugation and washing with absolute ethanol and deionized water respectively, and make hollow silica microspheres after drying;

[0045] (2) Preparation of amino-modified hollow silica microspheres

[0046] Add 1g of hollow silica microspheres into a three-necked flask, add 100m of absolute ethanol, after ultrasonication for a period of time, add 5ml of γ-aminopropyltriethoxysilane, heat at 90°C for 25 hours, centrifuge, wash and dry Prepare amino-modified hollow silica microspheres;

[0047] (3) Synthesis of intermediate 1

[0048] Add 0.5g of 4-formyltriphenylamine, 0.19g of hydroxylamine hydrochloride, and 0.28g of triethylamine into t...

Embodiment 3

[0054] (1) Preparation of hollow silica microspheres

[0055] Add 0.3g of polyacrylic acid into 4.5ml of ammonia water and mix it with 90ml of absolute ethanol, then divide 2.0ml of tetraethyl orthosilicate into the mixed solution five times with an interval of 1 hour, and react under magnetic stirring 15h, then carry out two times of centrifugation and washing with absolute ethanol and deionized water respectively, and make hollow silica microspheres after drying;

[0056] (2) Preparation of amino-modified hollow silica microspheres

[0057] Add 1g of hollow silica microspheres into a three-necked flask, add 80ml of ethanol and 20ml of distilled water to mix, after a period of ultrasonication, add 8ml of γ-aminopropyltriethoxysilane, heat at 90°C for 20 hours, centrifuge and wash , drying to obtain amino-modified hollow silica microspheres;

[0058] (3) Preparation of Intermediate 1

[0059] Add 0.5g of 4-formyltriphenylamine, 0.19g of hydroxylamine hydrochloride, and 0.30...

PUM

| Property | Measurement | Unit |

|---|---|---|

| size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com