Corrosion inhibitor and covered electrical cable with terminal

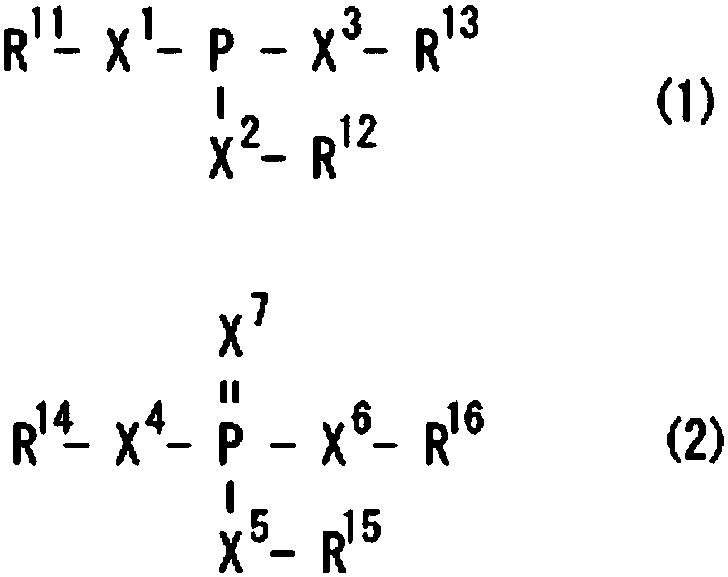

一种防腐蚀剂、碳原子数的技术,应用在防腐涂料、电路、导电连接等方向,能够解决难以薄薄均匀涂布、润滑脂粘稠性高等问题,达到抑制流出、保持力提高、维持防腐蚀性能的效果

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

[0084] Hereinafter, although an Example demonstrates this invention, this invention is not limited to an Example.

[0085] (Preparation of metal adsorption components)

preparation example 1

[0086] OL-Ca

[0087] Into a 500 ml flask, 50 g (acid value: 0.163 mol) and 50 mL of methanol were added ("Phoslex A18D" manufactured by SC Organic Chemical Co., Ltd., molecular weight: 467 (average), acid value: 183 mgKOH / g) and methanol, and stirred at room temperature. , to make a homogeneous solution. 6.04 g (0.0815 mol) of calcium hydroxide was added thereto. The suspension was stirred for 24 hours while maintaining room temperature, and after confirming the disappearance of the calcium hydroxide precipitate, it was filtered, and methanol and generated water were distilled off under reduced pressure using a rotary evaporator. Next, after adding 50 mL of toluene, similarly distilled off under reduced pressure, the generated water was distilled off by azeotropy to obtain the target product as a clear viscous substance.

[0088]

[0089] The metal adsorbing component obtained in Preparation Example 1 and the base oil were mixed at a predetermined ratio under heating at ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| viscosity index | aaaaa | aaaaa |

| viscosity index | aaaaa | aaaaa |

| viscosity index | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com