Patents

Literature

41results about How to "Solve the problem of high temperature resistance" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

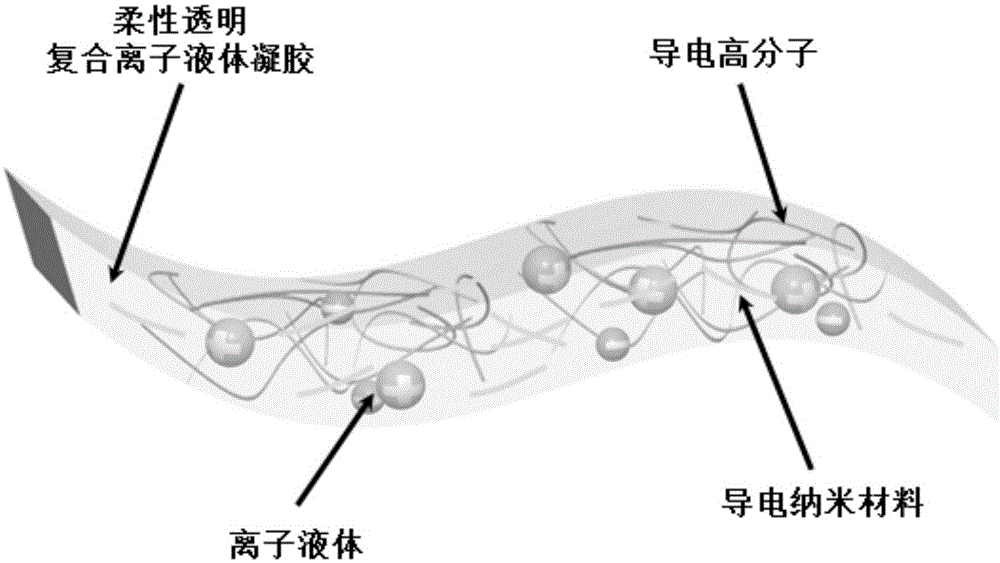

Preparation method for flexible and transparent composite ionic liquid gel conductive electrode

ActiveCN105140408ASolve the problem of high temperature resistanceStable in natureSolid-state devicesSemiconductor/solid-state device manufacturingPolymer networkSolar cell

The invention relates to a preparation method for a flexible and transparent composite ionic liquid gel conductive electrode. In the composite ionic liquid gel conductive electrode disclosed by the invention, a polymer monomer and an ionic liquid monomer form a flexible and transparent polymer network framework, and the conductivity of the composite ionic liquid gel conductive electrode is improved by introducing a conductive nano material. The invention also discloses a preparation method of the composite ionic liquid gel for the flexible and transparent electrode. In the flexible and transparent composite ionic liquid gel conductive electrode provided by the invention, a flexible and transparent substrate is not required to beintroduced, the mechanical property is excellent, and the defects of poor adhesiveness, poor chemical stability of the substrate and low temperature resistance caused by poor matching of the substrate and a conductive thin film in the traditional flexible and transparent electrode technology are overcome; the preparation method has the characteristics of simplicity in process, low cost and long-term stability; and moreover, the resistance of the composite ionic liquid gel can be adjusted, and thus, the transparent electrode is particularly suitable for fabrication of a wearable electronic device, a flexible display screen, a solar cell, a thin film transistor and an organic electroluminescence (EL) panel.

Owner:BEIJING NATURE STONE SCI TECH DEVP

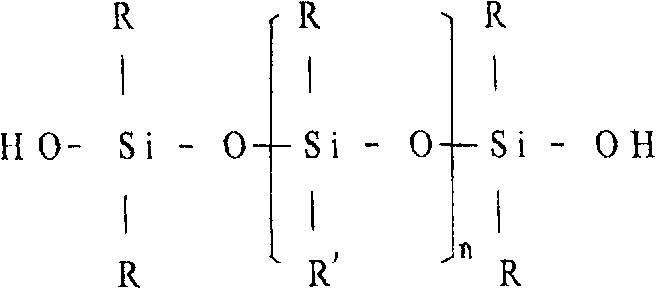

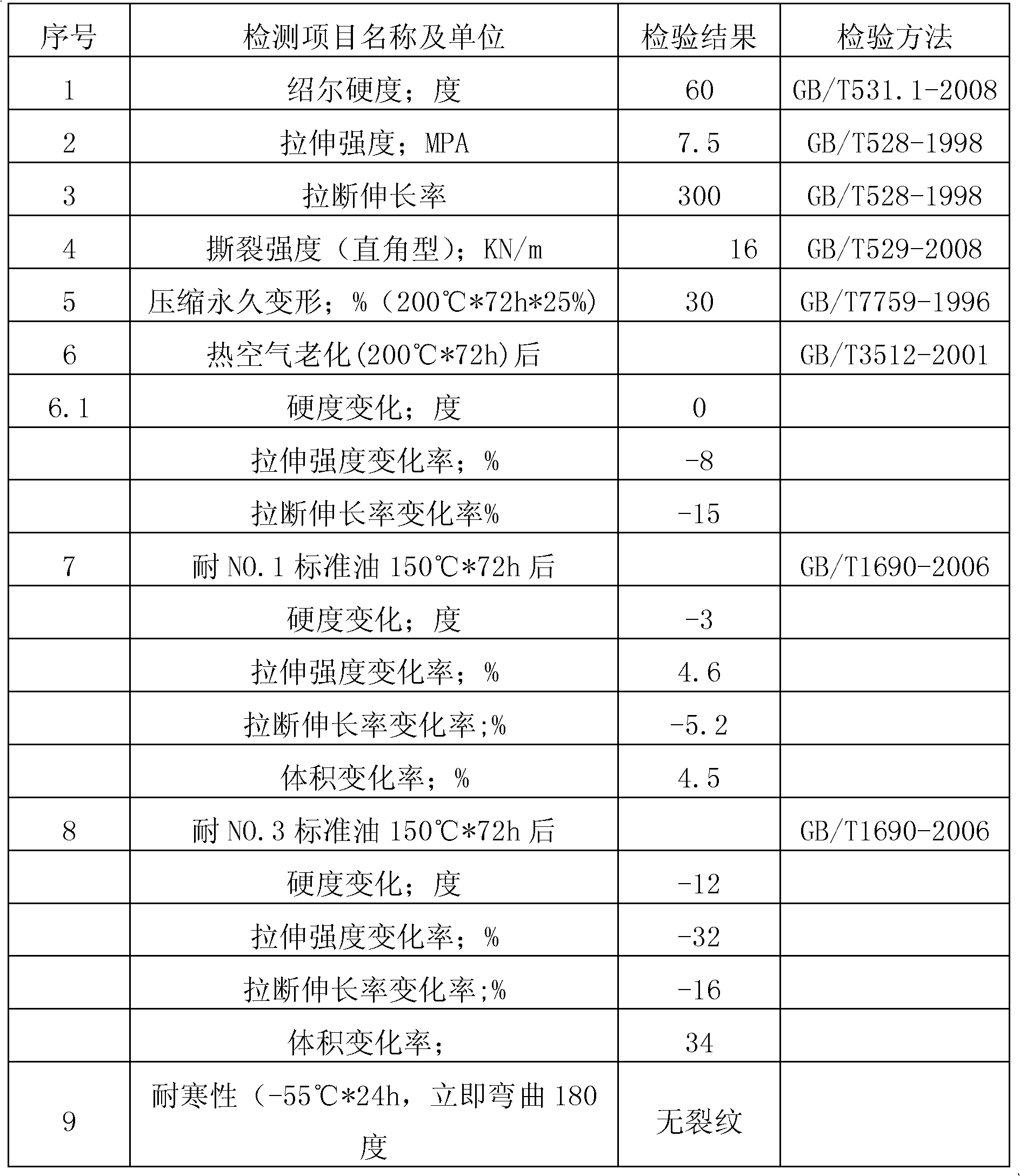

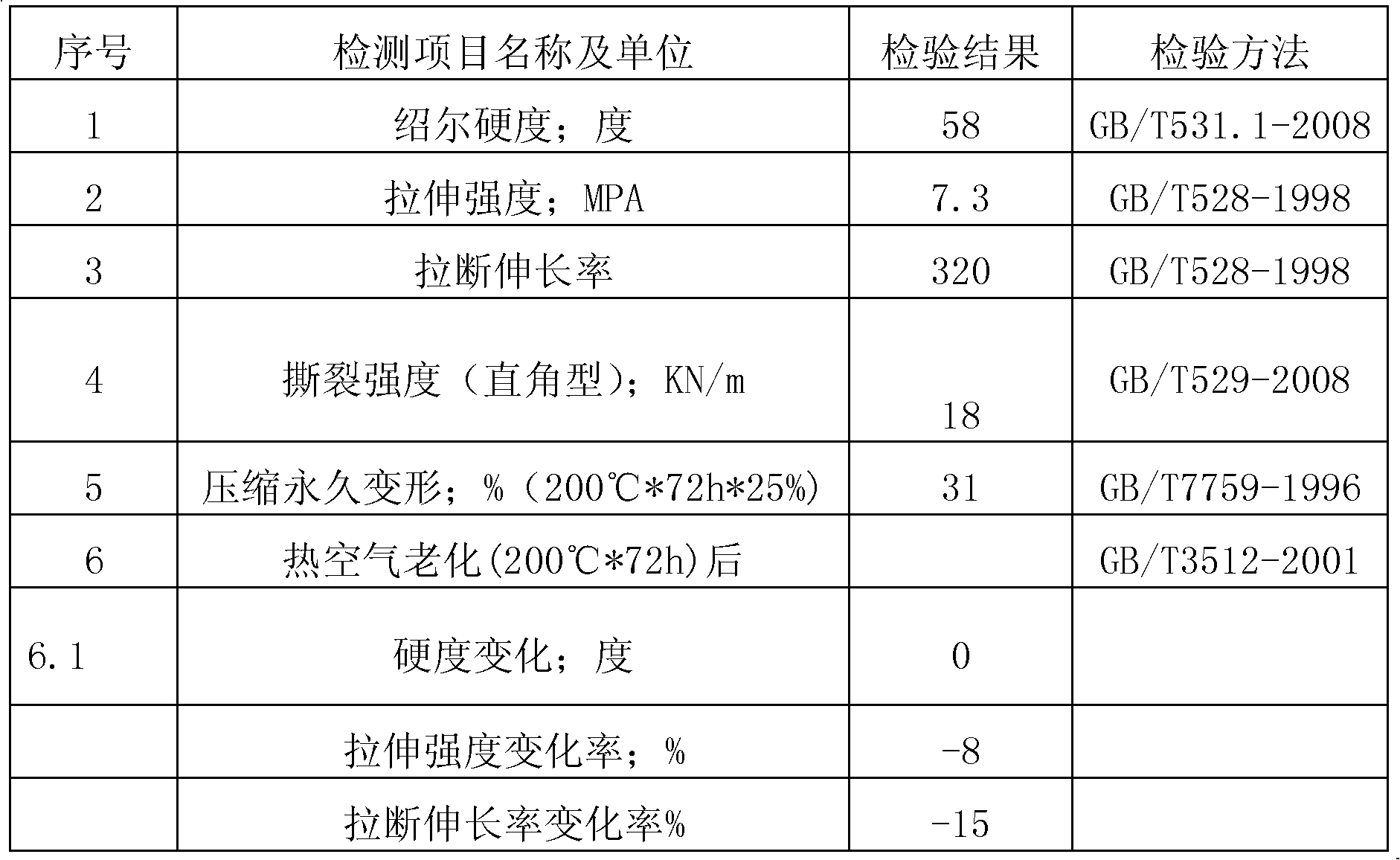

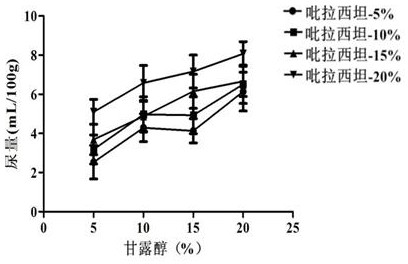

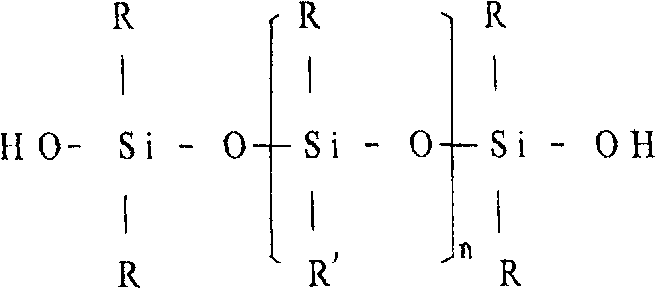

Oil-resistant silicon rubber

InactiveCN102585514ASolve the problem of high temperature resistanceLow costCarbon blackPolytetrafluoroethylene

The invention provides an oil-resistant silicon rubber composition. The composition comprises the following components in parts by weight: (a) crude methylvinyl silicon rubber including 71+ / -2 parts of methylvinyl silicon rubber containing 0.07-0.09 percent of vinyl and 29+ / -2 parts of methylvinyl silicon rubber containing 0.15-0.17 percent of vinyl, wherein the number average molecular weights of the two types of rubber are 580,000-620,000, (b) 2.2+ / -0.5 parts of hydroxyl silicon oil, (c) 1.4+ / -0.2 parts of hydrogen-containing silicon oil and (d) an oil-resistant component including 42+ / -10 parts of white carbon black which is precipitated white carbon black, 1.1+ / -0.2 parts of dimethyl silicon oil of which the polymerization degree is between 150 and 300, 9+ / -2 parts of pot clay of 3000+ / -500 meshes, and 5+ / -0.5 parts of polytetrafluoroethylene, wherein the total weight of the components (a), (b), (c) and (d) accounts for 90-100 percent of the total weight of the composition. The invention further provides oil-resistant silicon rubber and a preparation method and an application thereof.

Owner:上海旭创高分子材料有限公司

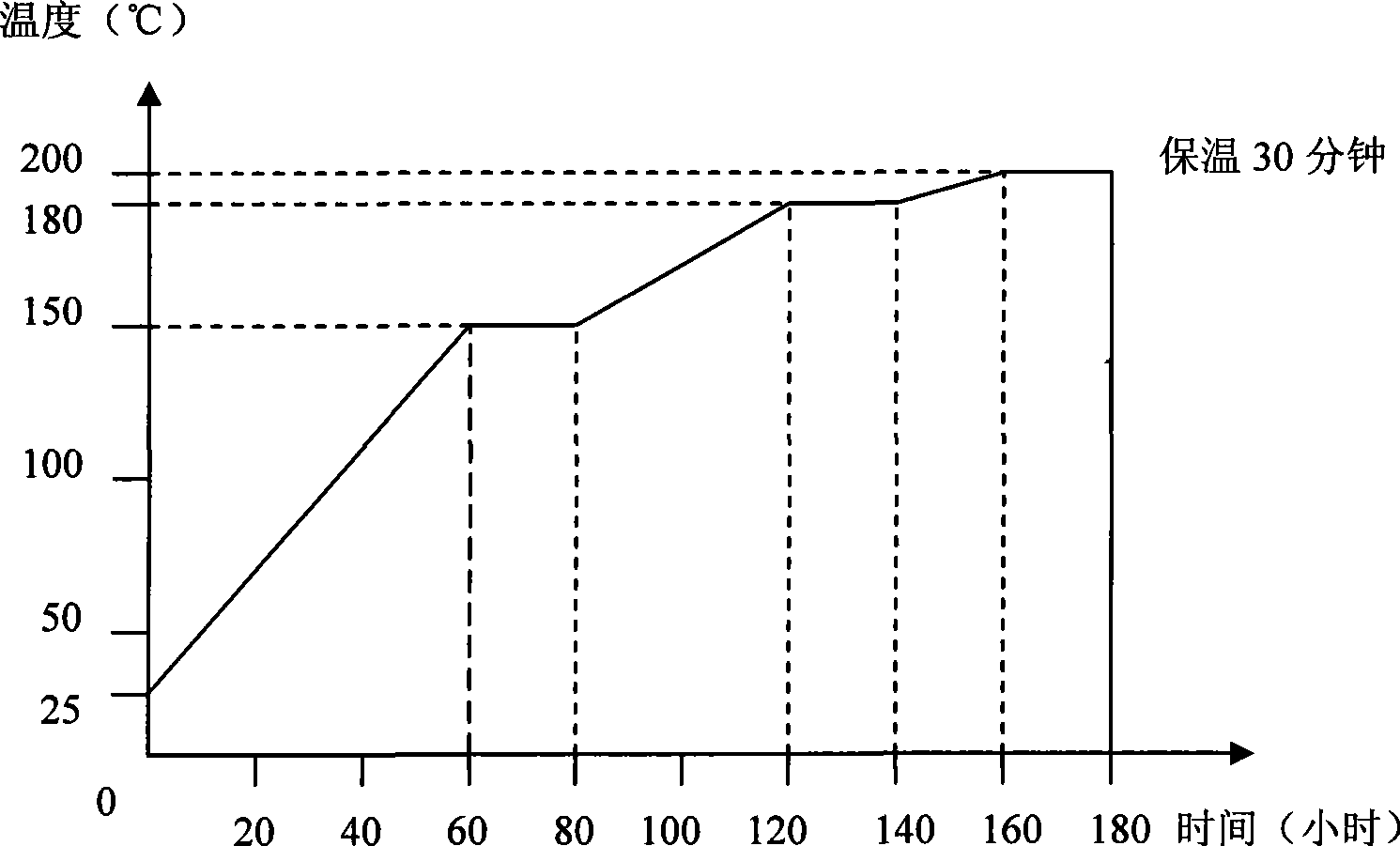

High temp. resistance capsule, and its prepn. method

InactiveCN1459330ASolve the problem of high temperature resistanceHigh heat resistanceMicroballoon preparationMicrocapsule preparationHigh resistanceEpoxy

A high-temp. resistant capsule features that its capsule core contains at least one functional substance A and a volatile substance B which can dissolve capsule core but is insoluble in dispersing medium. The substance A is chosen from paraffin wax, chlorinated paraffin wax, high-grade emtrol and fatty acids, epoxy resin, perfume or essence and coloring agent. The substance B contains at least one hydrophobic substance whose boiling point is between ordinary temp. and 150 deg.C. Its preparing process features heat treatment of conventional capsule, that is, baking at 70-90 deg.C to constant weight and heat treating at 130-190 deg.C for 30-150 min. Its advantages are high resistance to high temp. up to 290 deg.C and low cost.

Owner:TIANJIN POLYTECHNIC UNIV

Expandable biopolymer temporary plug profile control agent and preparation method thereof

InactiveCN105647496AImprove temperature resistanceSolve the problem of high temperature resistanceDrilling compositionPollutionProcess conditions

Owner:张向南

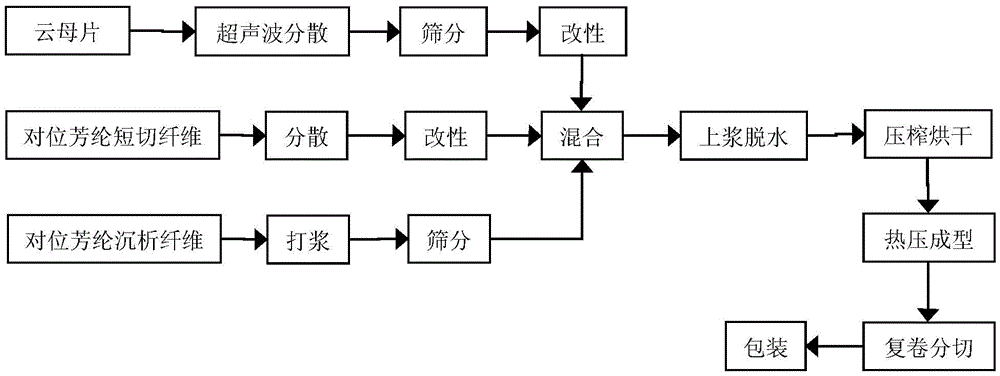

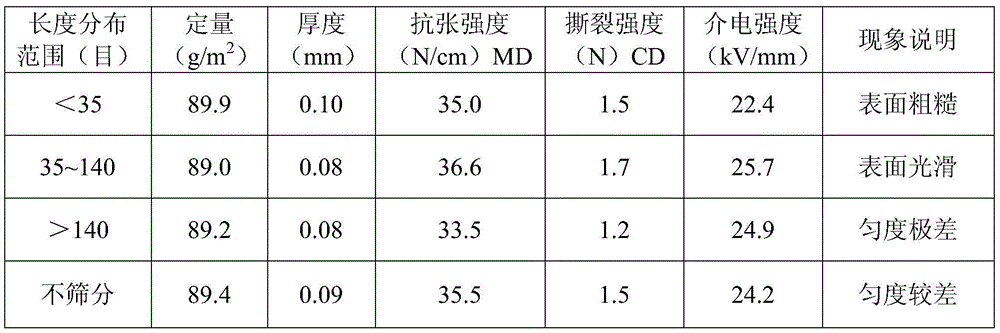

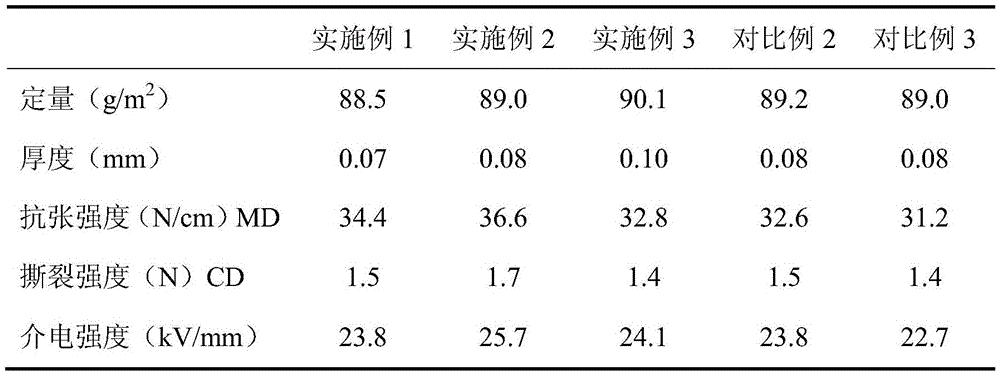

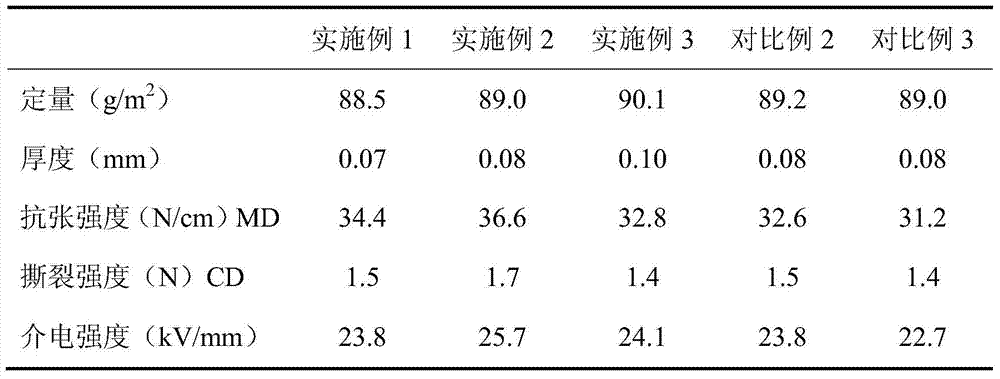

Preparation method of p-aramid fiber-mica paper

ActiveCN105544286AHigh strengthImprove evennessInorganic fibres/flakesPhysical paper treatmentDielectric breakdown strengthSlurry

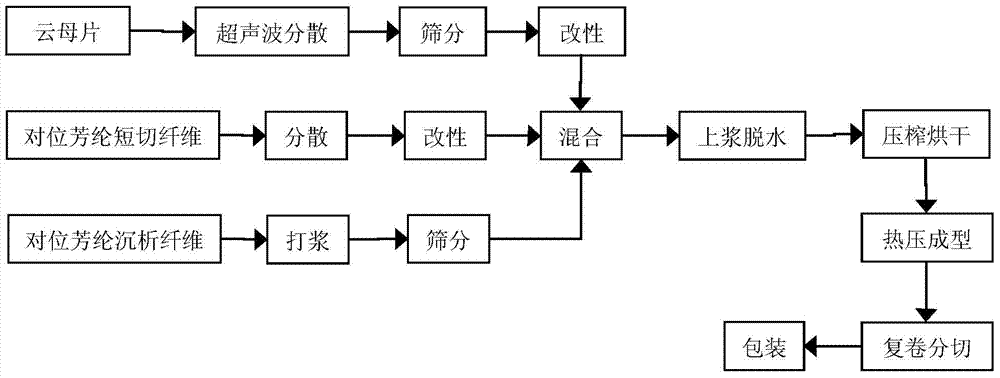

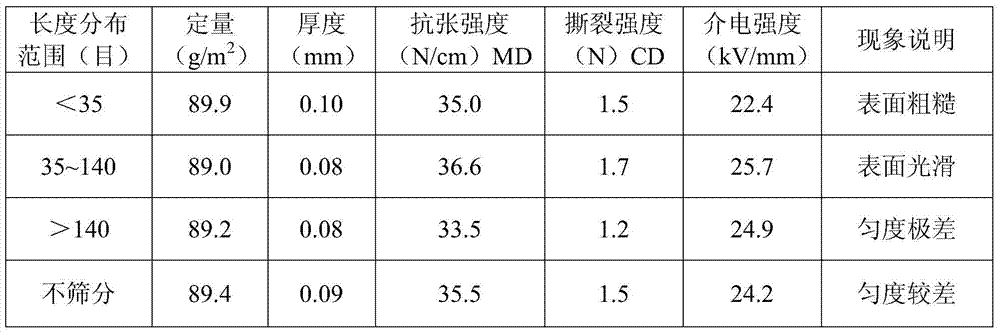

The invention relates to a preparation method of a p-aramid fiber-mica paper. The preparation method comprises defibering and dispersing silane coupling agent-modified p-aramid chopped fibers to obtain slurry A, carrying out screening on the p-aramid fibrids with a beating degree of 40-65 degrees SR to obtain slurry B, modifying mica plates through an ionic starch solution to obtain modified mica plates, mixing the slurry A, the slurry B and the modified mica plates to obtain uniform mixed slurry, wherein the uniform mixed slurry comprises, by mass, 10-20% of p-aramid chopped fibers, 20-40% of the p-aramid fibrids and 40-70% of the mica plates, carrying out sizing, dehydration and formation on the mixed slurry, carrying out squeezing and drying and carrying out hot press molding to obtain the p-aramid fiber-mica paper. The p-aramid fiber-mica paper obtained through fiber screening and modification, wet method paper making and hot pressing molding has good evenness, excellent mechanical strength, excellent dielectric breakdown strength and high temperature resistance stability.

Owner:YANTAI METASTAR SPECIAL PAPER

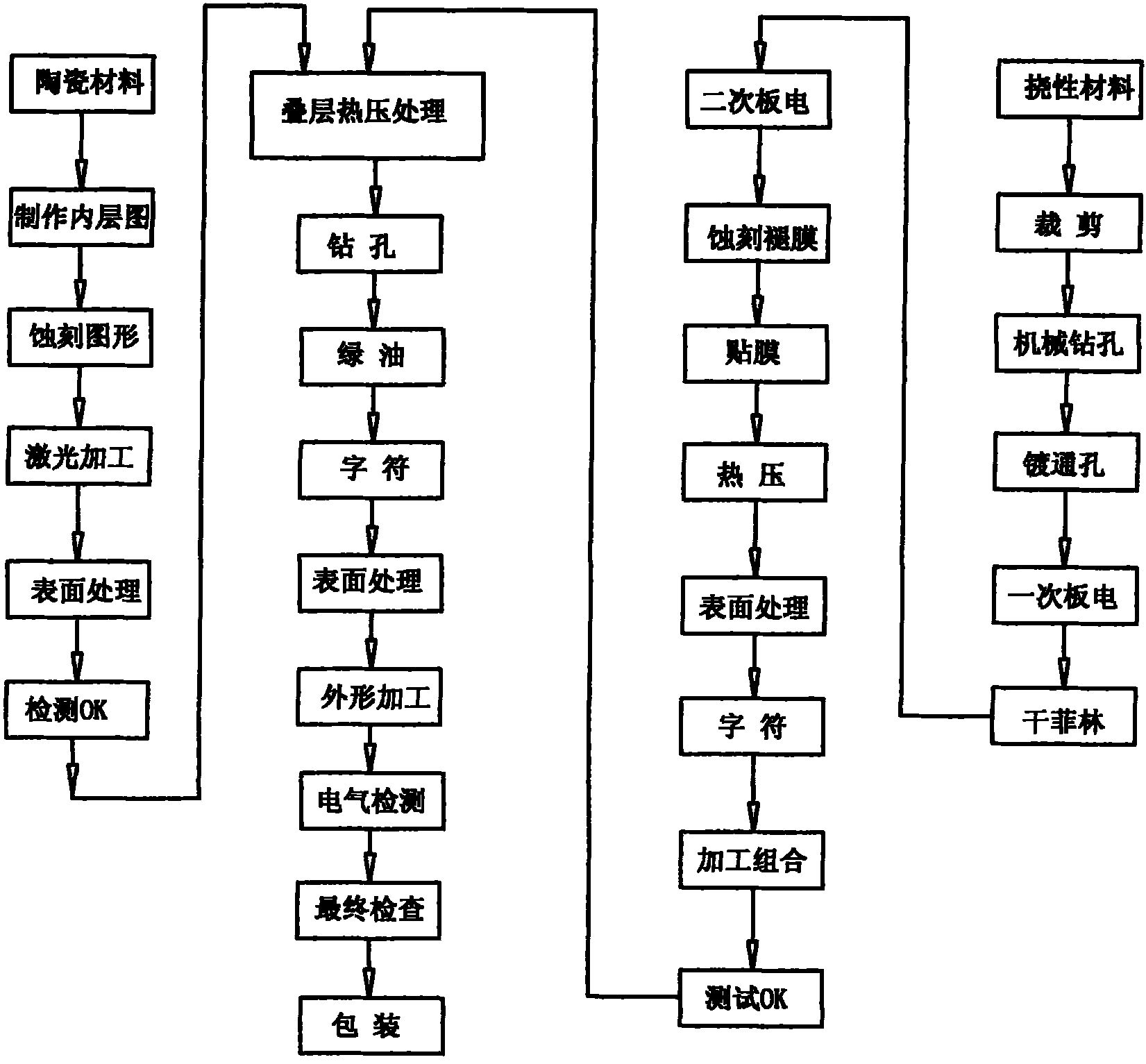

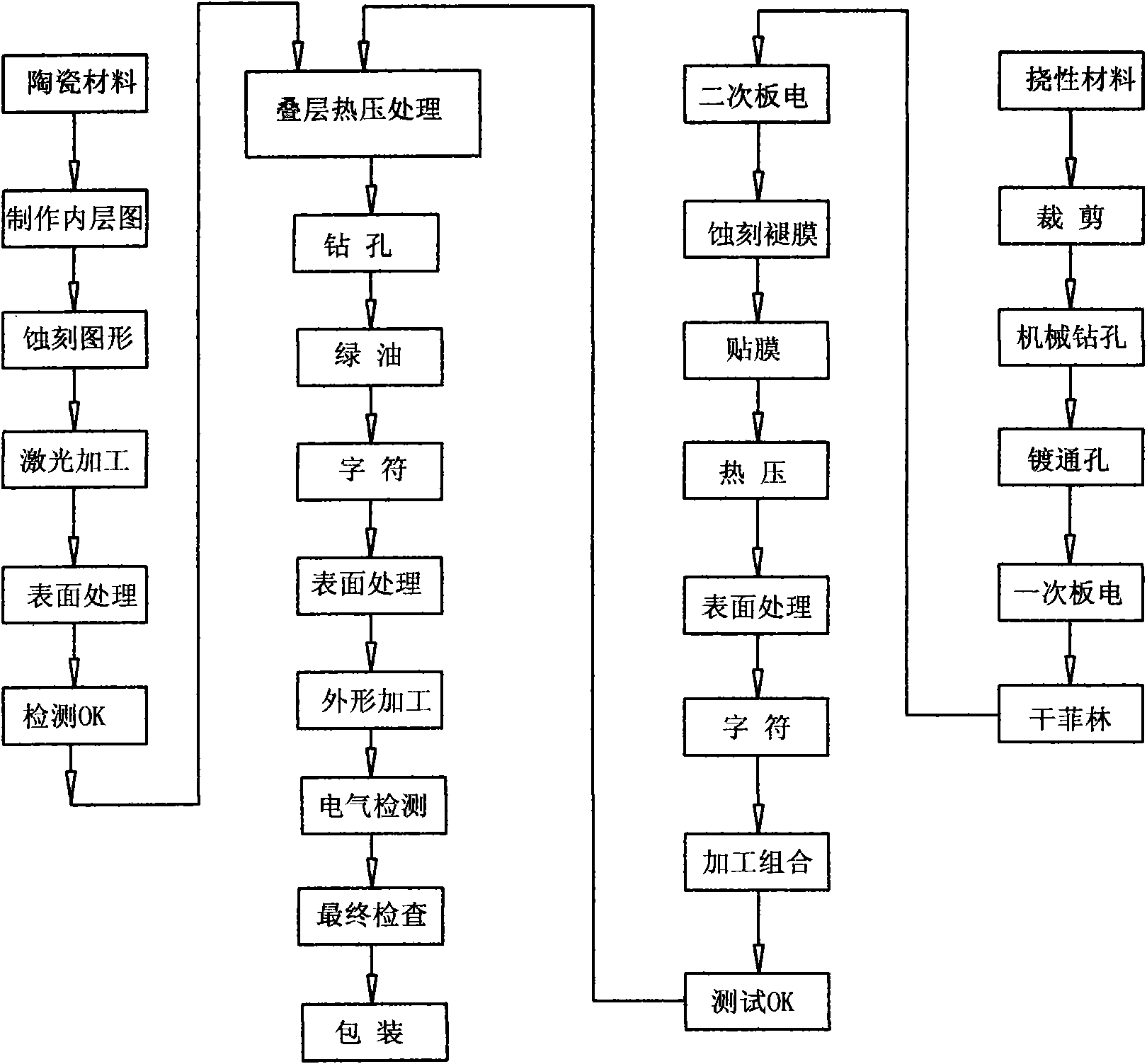

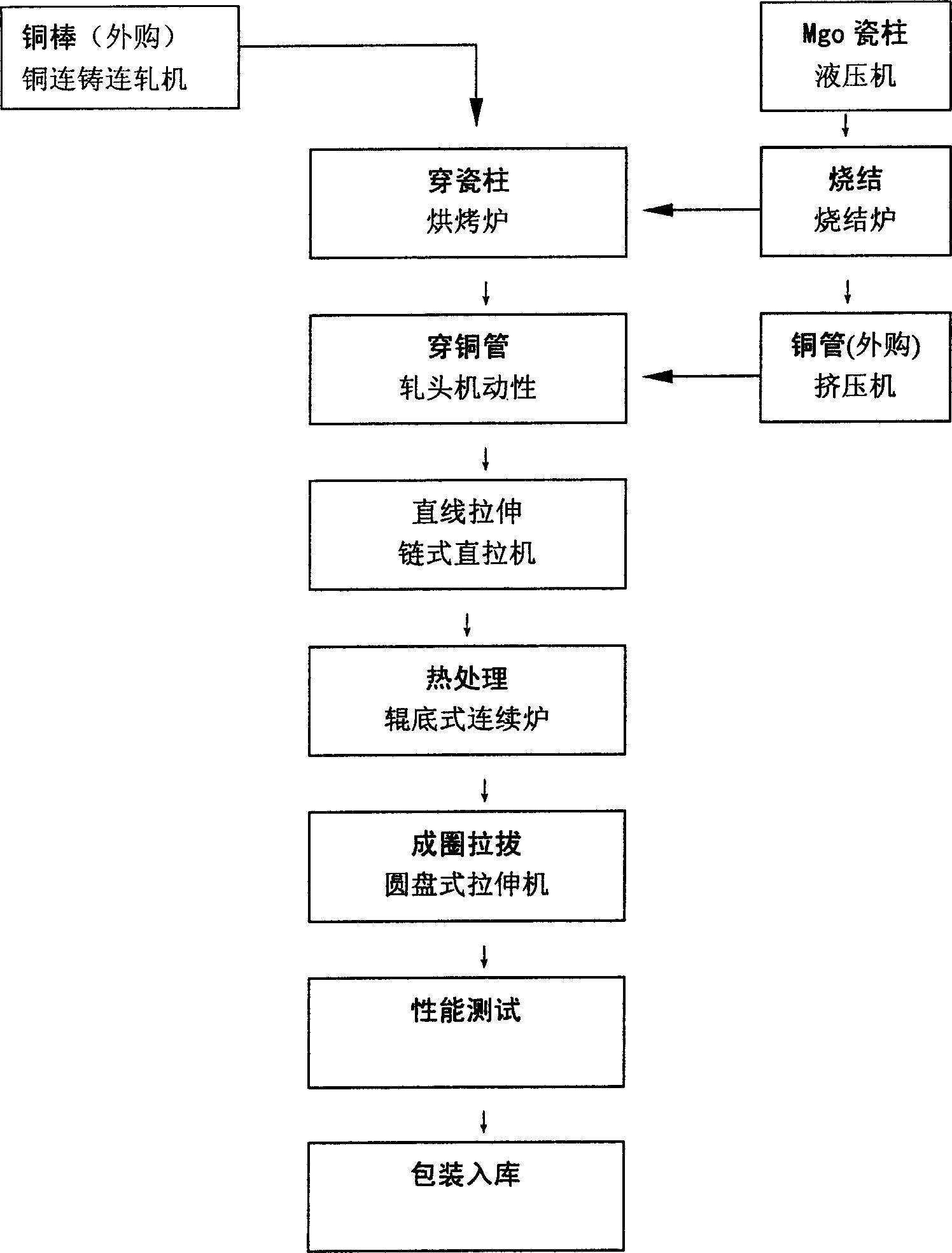

Method for manufacturing ceramic-based flexible circuit board

InactiveCN101990369ASolve the problem of high temperature resistanceExcellent 3D connection characteristicsMultilayer circuit manufactureCeramicResist

The invention discloses a method for manufacturing a ceramic-based flexible circuit board, which is characterized by comprising the following steps of: A. manufacturing an aluminum nitride ceramic circuit board; B. manufacturing a flexible circuit board; C. laminating the aluminum nitride ceramic circuit board and the flexible circuit board; D. manufacturing a through hole passing through the upper surface and the lower surface of the multilayer board on the multilayer board obtained in the step C by adopting laser drilling equipment, processing the hole with a conducting material and then drying to obtain a through hole; E. printing solder resist ink in the positions on the multilayer board, at which electronic elements do not need to be welded; F. silk printing characters at preset positions on the multilayer board; and G. cutting the circuit board into predetermined specifications by adopting laser cutting equipment to obtain the ceramic-based rigid flexible multilayer circuit board. The invention aims to overcome the defects in the prior art and provide the manufacturing method of the ceramic-based flexible circuit board with simple process, good 3D connection performance and good thermal conductivity.

Owner:广东达进电子科技有限公司

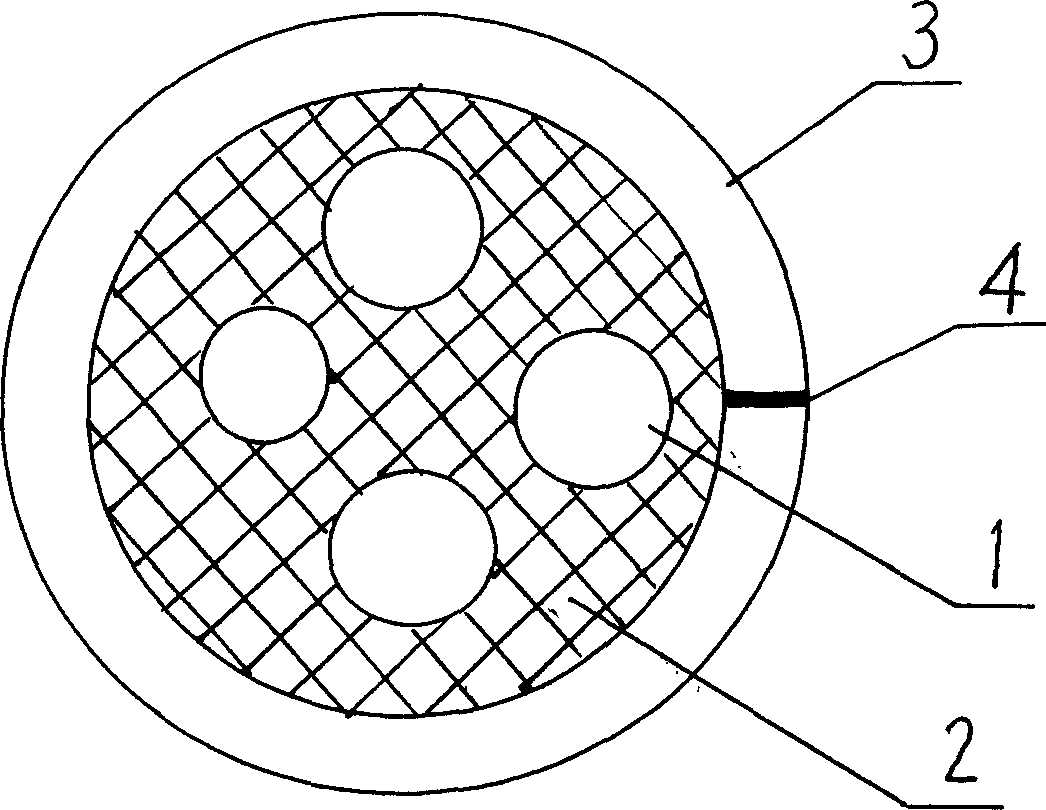

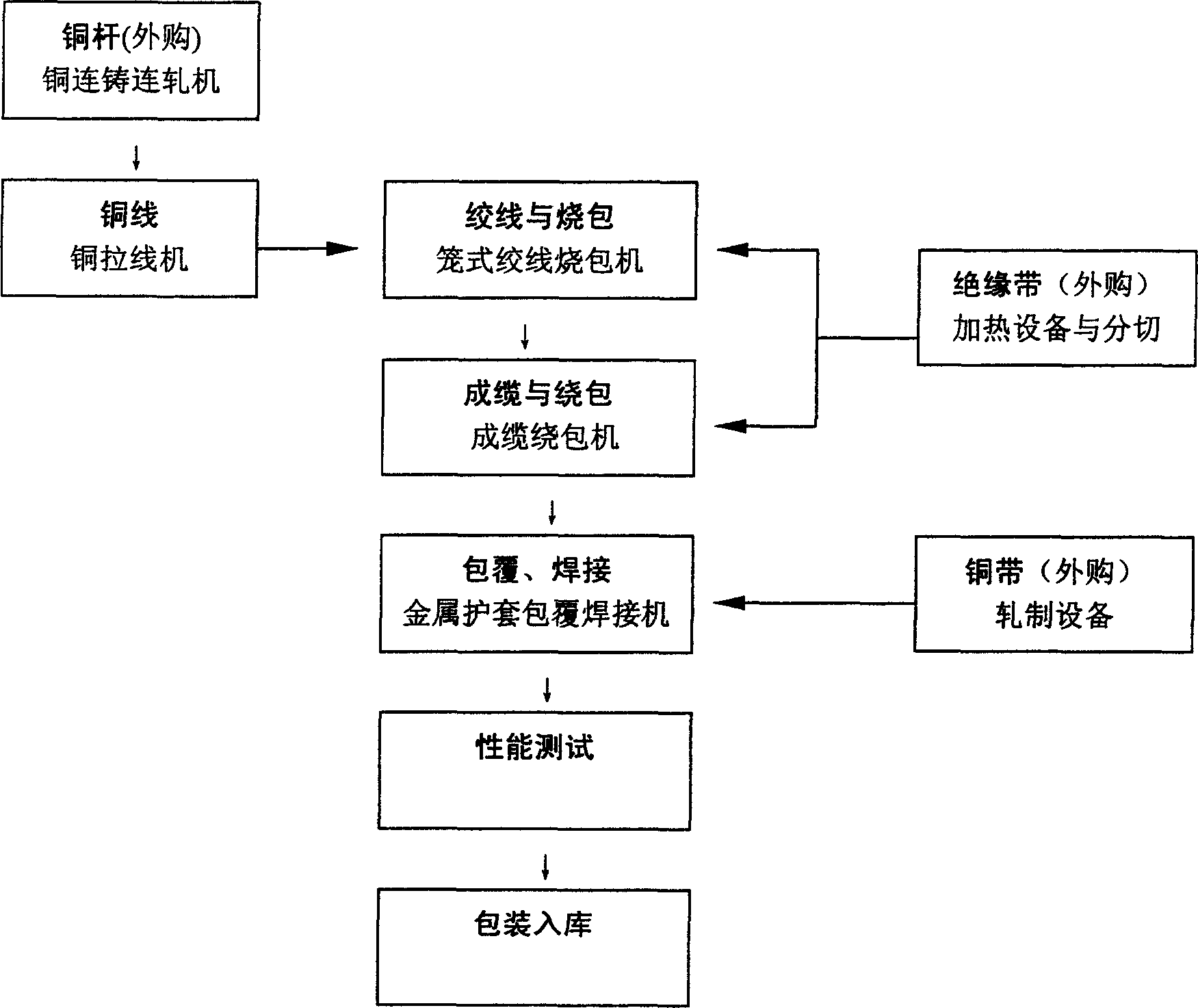

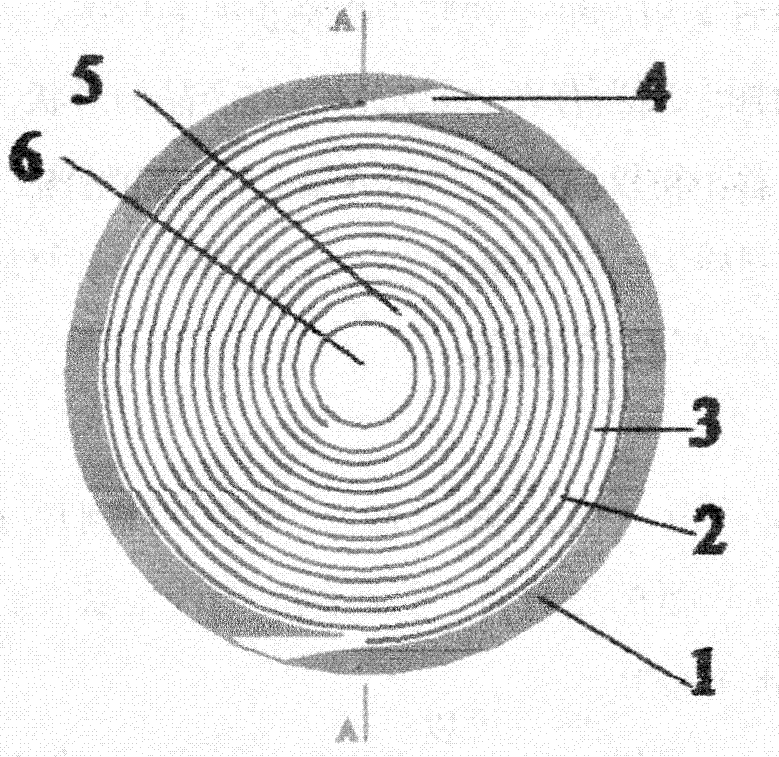

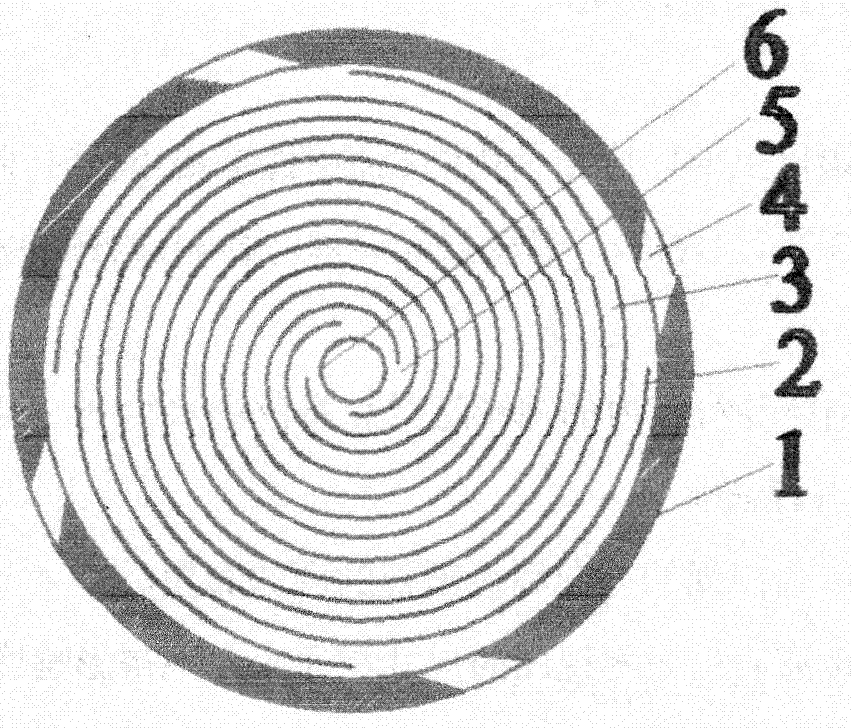

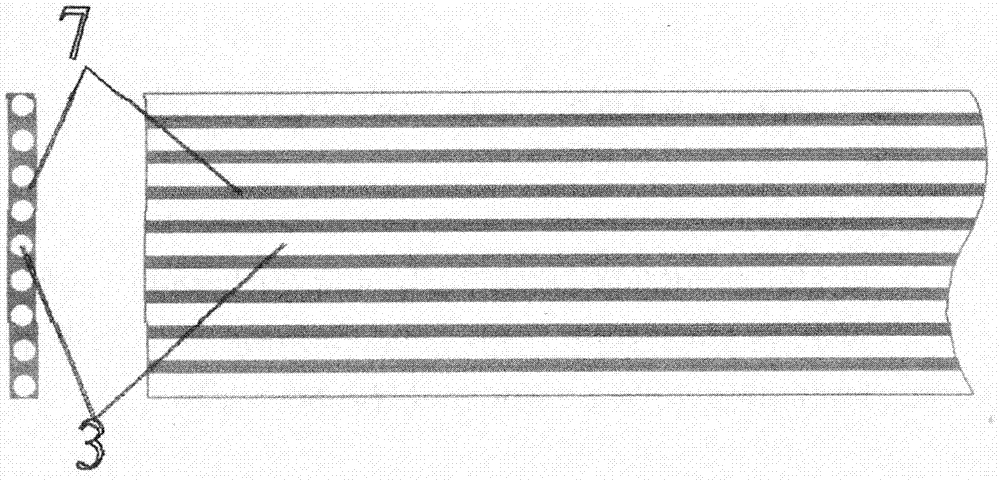

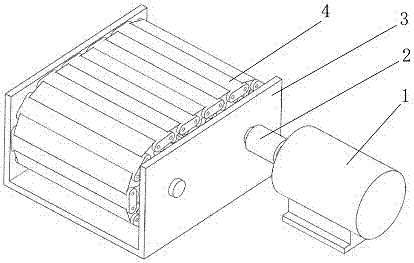

Flexible fire-proof cable and its producing process and producing device

InactiveCN1588563ASimple production processSolve the problem of high temperature resistanceInsulated cablesPower cablesPower cableHazardous substance

The invention is a flexible fireproof cable and its producing process as well as its producing equipment. It uniformly distributes a group of metal wire cores, which are mutually isolated and coated in the vertical direction by mica tape insulating layer and then coats a metal tape outside, the metal tape is folded annularly and closed vertically by a welding line, thus composing the flexible fireproof cable. If it needs a better bending property, it can roll lines on a smooth metal protective cover. Its producing equipment is composed mainly of a twisted wire winder, a cable winder and a metal protective cover coat-welding machine connected in series in sequence. It solves the problems of high temperature resistance, safety and environmental protection as well as process complexity, cable hardness, cable length, and insulating resistance. It can not fire, burn and produce smoke frog and harmful substances even if the surrounding substances have been firing and burning, so it is a permanent fireproof safe environmental protection cable.

Owner:上海胜武电缆有限公司

Preparation technology of high temperature resistant feeding cellulase

InactiveCN101381713ASolve the problem of high temperature resistanceAnimal feeding stuffAccessory food factorsCellulaseHigh heat

The invention relates to a process for preparing cellulase used for heat resisting feeds. The process comprises the following steps: screening out heat resisting strains for preservation by performing heat resisting domestication first on the strains for the cellulase used for feed production, and performing transfer of culture on the preserved strains; and then fermenting the screened heat resisting strains to prepare into the mixed enzyme liquid, and concentrating the mixed enzyme liquid to certain concentration to perform microcapsule coating. The process can improve the tolerance temperature of the cellulase used for the feeds from 65 DEG C keeping for 10 minutes to 85 DEG C keeping for 10 minutes, and basically solve the difficult problem that the cellulase used for the feeds does not resist high temperature, thereby laying the technical foundation for the wide application.

Owner:宝鸡市星星协力生物有限公司

N-doped crystalline silicon and preparation method thereof

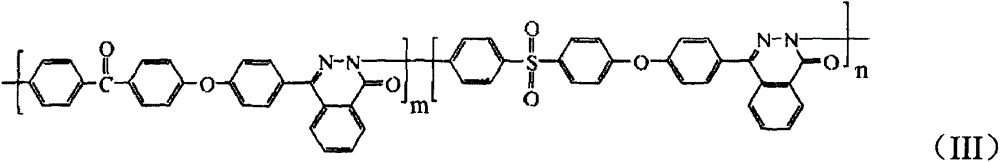

InactiveCN101864593AUniform nitrogen dopingNitrogen doping concentration is easy to controlPolycrystalline material growthFrom frozen solutionsFurnace roomSilicon nitride

The invention discloses a preparation method of an N-doped polysilicon ingot. The preparation method comprises the following steps of: putting polysilicon and silicon nitride nanopowder with the grain size of 1 to 100nm in a quartz crucible and charging, vacuumizing a furnace room and heating to 1420 to 1550 DEG C, and preserving the temperature till mixture is fused completely; gradually reducing the cooling speed in 1 to 10 DEG C / min in a furnace till reaching 1350 to 1420 DEG C; then naturally cooling the temperature in the furnace room to the room temperature; taking the silicon ingot out and crushing into small pieces to obtain master alloy silicon blocks; putting mixture of the master alloy silicon blocks, the polysilicon material and electrical activity dopants in the quartz crucible, vacuumizing the furnace room and heating to 1420 to 1550 DEG C to obtain a fused silicon material mixture; and enabling the fused silicon material mixture to solidify to obtain the polysilicon ingot. According to the preparation method of the N-doped polysilicon, the invention can carry out N-doping by adopting conventional devices and has even N-doping, high N-doping concentration, simple entire process and low cost. In addition, the invention also discloses a preparation method of an N-doped monocrystalline silicon ingot.

Owner:王敬 +1

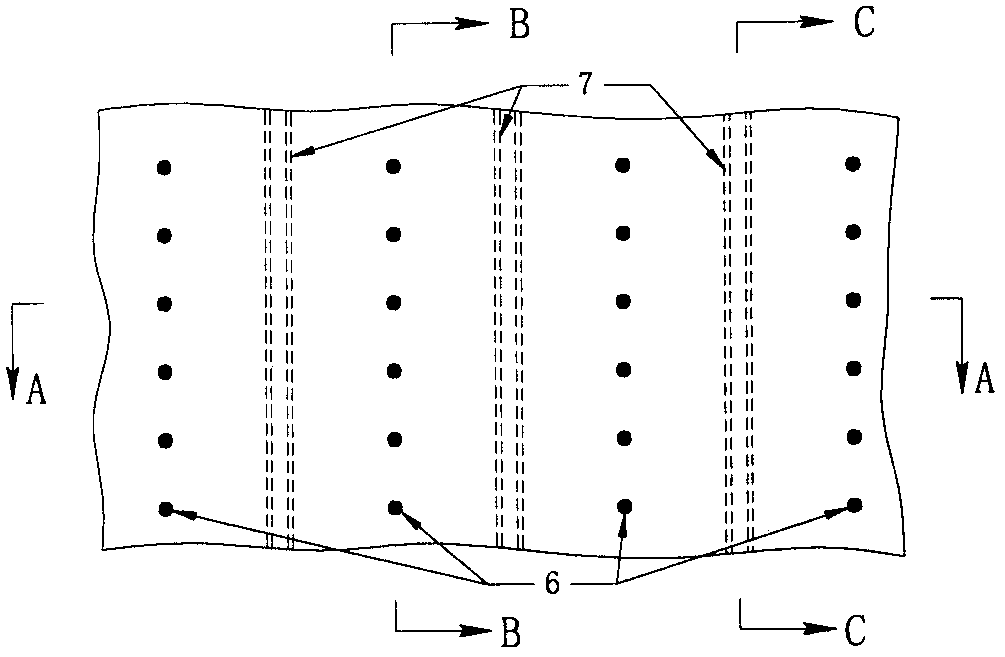

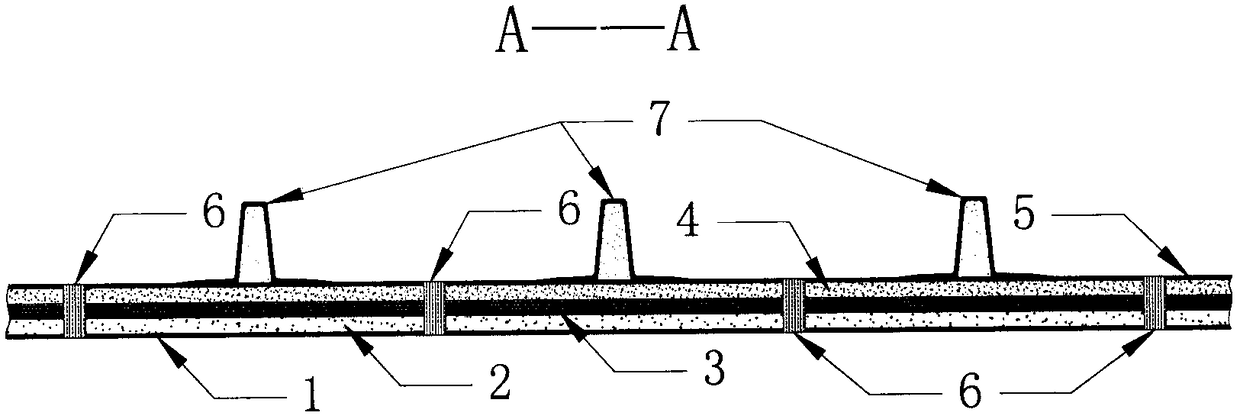

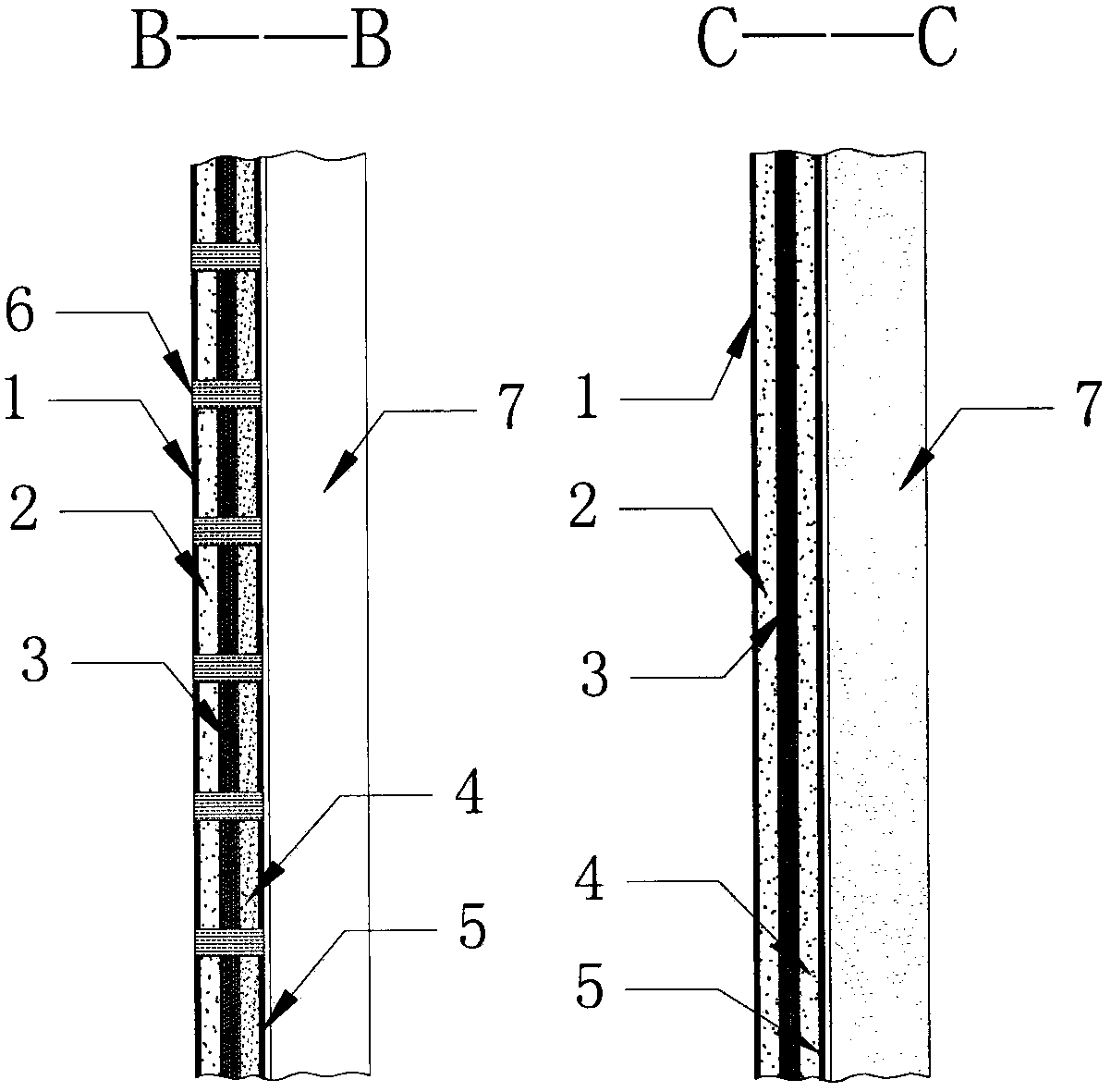

Pin-type load-bearing/protection integrated high-strength polyethylene composite armored bulkhead structure

InactiveCN109131724AImprove interlayer strengthImprove carrying capacityHull bulkheadsHull panellingsFiberInsulation layer

Owner:NAVAL UNIV OF ENG PLA

High temp. resistance capsule, and its prepn. method

InactiveCN1199721CSolve the problem of high temperature resistanceHigh heat resistanceMicroballoon preparationMicrocapsule preparationEpoxyAdhesive

The invention relates to a high temperature resistant capsule and a manufacturing method thereof. The product is characterized in that the capsule core includes at least one functional substance A and at least one volatile substance B capable of dissolving the capsule core but insoluble in the dispersion medium, and the volume ratio of the functional substance A to the volatile substance B is 19 : 1~1:1; the functional substance A refers to the following less volatile liquid or solid powder substances: paraffin-like substances, chlorinated paraffin-like substances, higher fatty alcohols, higher fatty acids, epoxy resin adhesives , fragrance or essence, coloring agent; the volatile substance B includes at least one of the following hydrophobic liquid substances with a boiling point lower than 150° C. but higher than room temperature. The manufacturing method is characterized in that conventionally obtained capsules are subjected to heat treatment, including drying at 70-90° C. to constant weight, and then heat-treating at 130° C.-190° C. for 30 minutes to 150 minutes. The invention has the advantages of simple process, low cost and strong applicability. Tests show that the high temperature resistance of the experimental capsule of the invention can reach 290°C.

Owner:TIANJIN POLYTECHNIC UNIV

Hose lining material for ultrahigh-pressure wire-wound hydraulic hose and preparation method of hose lining material

InactiveCN105949540ASolve the problem of high temperature resistanceMeet the use requirementsPressure wireActive agent

The invention discloses a hose lining material for an ultrahigh-pressure wire-wound hydraulic hose and a preparation method of the hose lining material. The hose lining material is prepared from raw materials in parts by weight as follows: 50-70 parts of nitrile butadiene rubber, 30-50 parts of a rubber and plastic alloy, 6-7 parts of an active agent, 3 parts of an anti-aging agent, 6 parts of a plasticizer, 80-85 parts of carbon black 774 and 3.5-3.7 parts of a vulcanization accelerator, and the material is prepared through primary smelting, mixing, extrusion and vulcanization procedures. The problems of failure in high temperature resistance, forming of pinholes and oil leakage of high-pressure wire-wound hydraulic hoses are solved, and the use requirements of high-pressure and high-pulse wire-wound hydraulic hoses are met.

Owner:HENGSHUI JIDIER SPECIAL RUBBER HOSE CO LTD

Preparation method for plant sterol ester

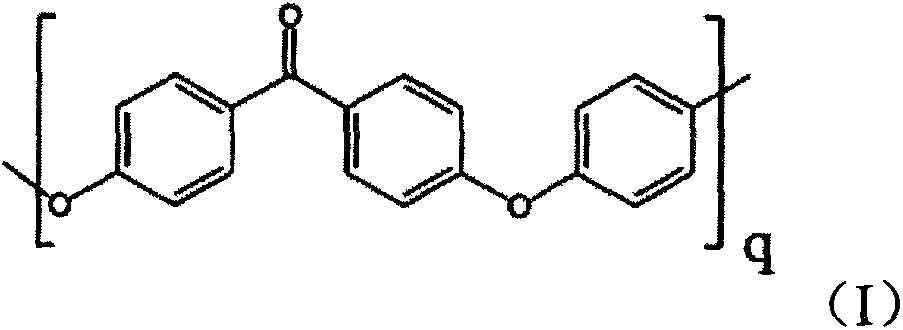

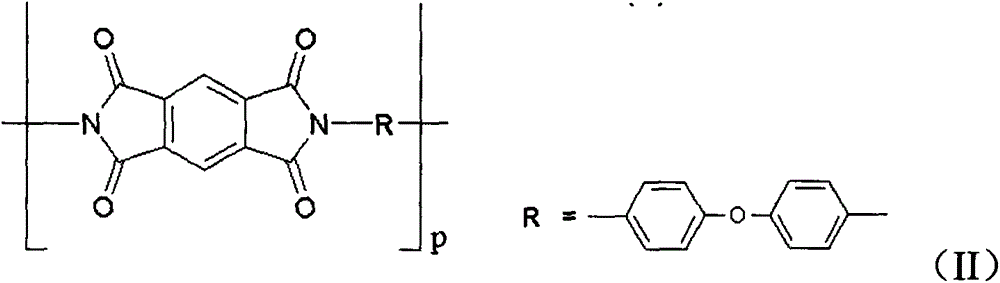

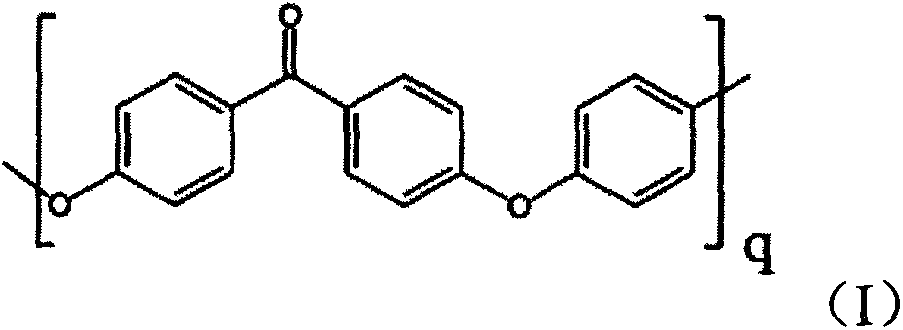

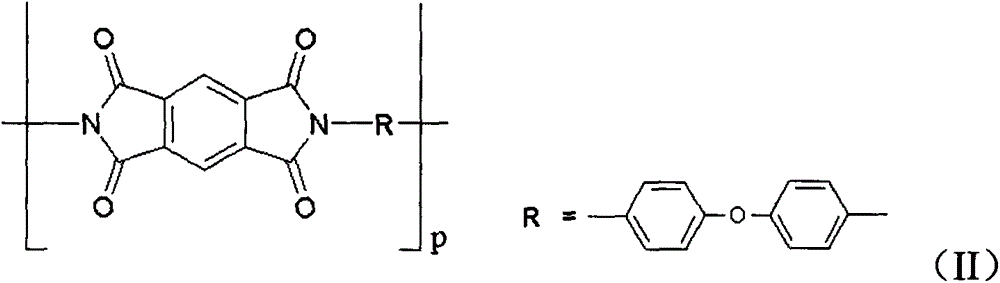

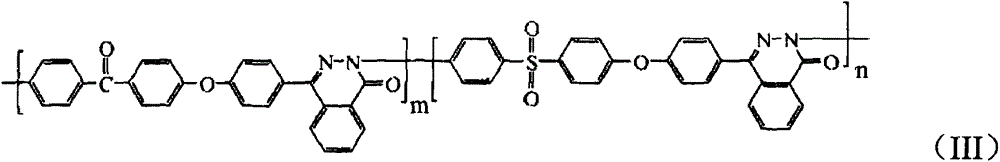

ActiveCN104402958ASolve the problem of high temperature resistanceImprove conversion rateOrganic-compounds/hydrides/coordination-complexes catalystsCatalytic reactionsPoly ether ether ketoneSide chain

The invention relates to a preparation method for plant sterol ester. The method comprises the following steps: 1, stirring phytosterol and fatty acid under a vacuum condition in the presence of a high-temperature resistant polymer catalytic membrane, and heating the phytosterol and the fatty acid to be molten; 2, heating the phytosterol and the fatty acid to specified reaction temperature at constant speed, and performing thermostatic reaction; 3, separating a product mixture from the catalytic membrane after the reaction is ended; 4, adding alcohol for washing, performing stirring and standing demixing, and repeatedly washing a lower oil layer with alcohol; 5, performing vacuum rotary evaporation on the lower oil layer to obtain plant sterol ester after centrifugal demixing, wherein the high-temperature resistant polymer catalytic membrane is a polymer material of which the main chain is one of polyetheretherketone, poly-p-phenylene terephthamide, polyimide and polyaryletherketone and the side-chain radical is a catalytic active radical. According to the preparation method, the problems of corrosion to equipment, difficulty in product separation, environmental pollution, solid catalyst residues, high-temperature irresistance of cation exchange resin and more side reaction caused by reactant adsorption of resin micropores of homogeneous catalysis are solved.

Owner:江苏膜芮环保科技有限公司

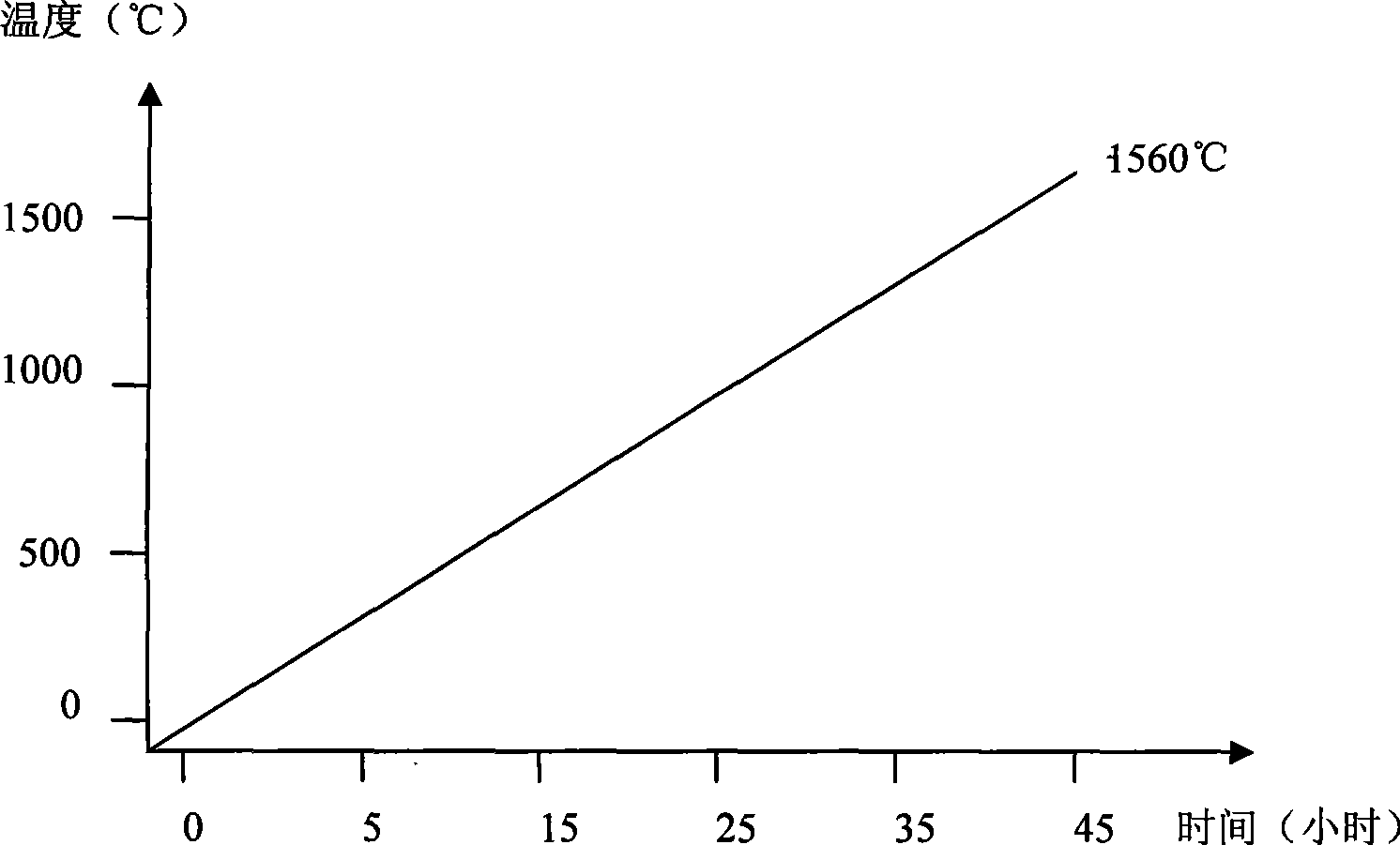

Low-temperature curing ceramic powder and method for producing the same

The invention relates to low temperature curing ceramic powder and a method for preparing the same, which belongs to the technical field of material. The ceramic powder comprises the following compositions in weight percentage: 42 to 50 percent of Al2O3, 15 to 18 percent of SiO2, 3.5 to 6.5 percent of MgO, 28 to 35 percent of thermosetting plastic PA, and 0.5 to 1 percent of thermosetting plastic PC. The method for preparing the low temperature curing ceramic powder comprises the following steps: performing high temperature pre-sintering and ball milling on the Al2O3, the SiO2 and the MgO respectively, and then removing the water through drying; performing low temperature presintering and water vapor heating on the thermosetting plastic PA and the thermosetting plastic PC, and then screening out the part of which the fineness is between 250 and 300 meshes; and mixing inorganic materials and organic materials after the treatment, stirring the materials evenly to preparing the low temperature curing ceramic powder. Through a test under the condition that the temperature is between 40 DEG C below zero and 1,500 DEG C, the air velocity is 200 meters per second, the airflow pressure is 2 MPa and the vibration frequency is 2,500 Hz, the low temperature curing ceramic powder is proved to have stable material performance and excellent comprehensive effect, and can be a filling insulating material for various types of thermocouples.

Owner:SHENYANG LIMING AERO-ENGINE GROUP CORPORATION

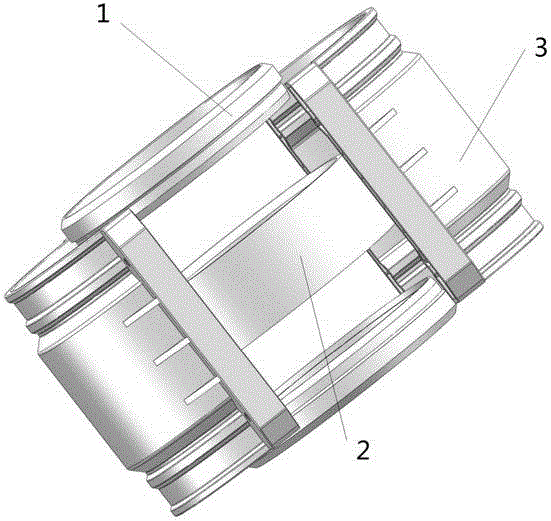

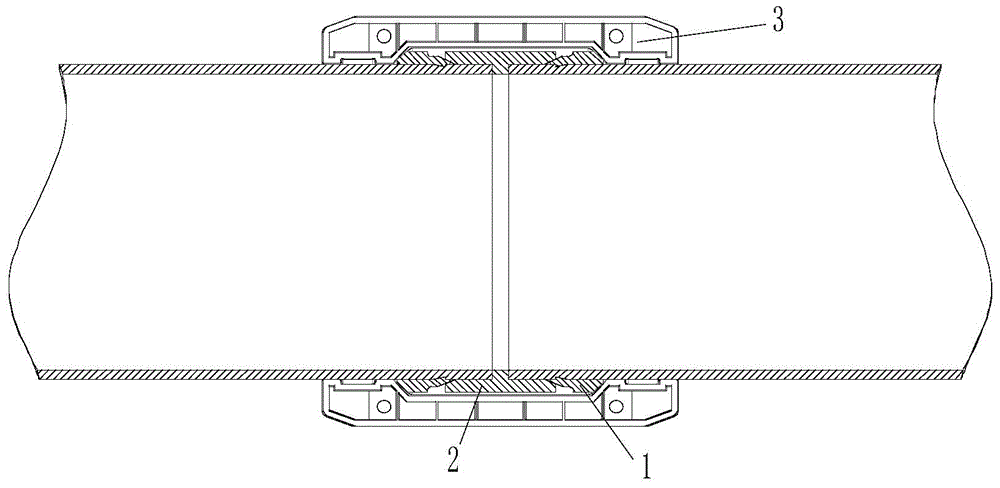

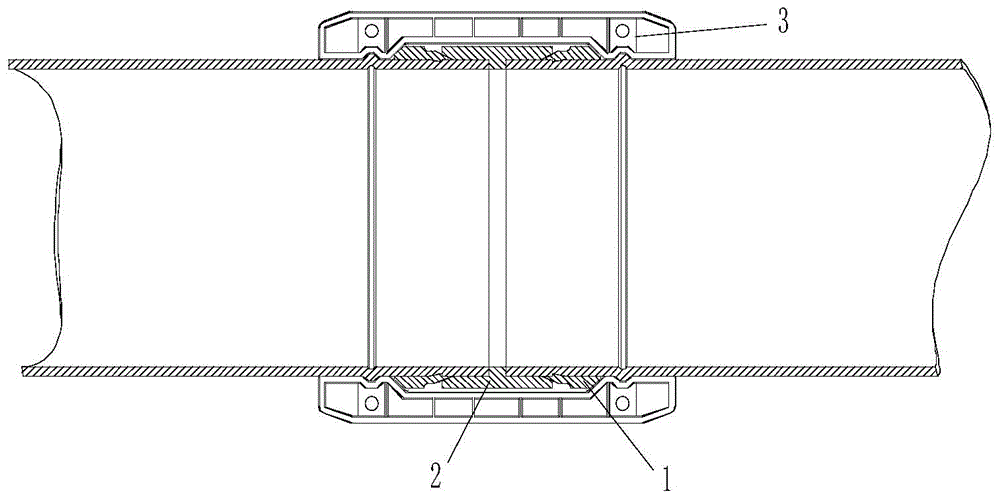

High pressure resistant leakage-proof metal sealing clamp hoop locking type large diameter pipeline connecting device

InactiveCN104879580AImprove applicabilityReduced finish requirementsSleeve/socket jointsEngineeringHigh pressure

The invention provides a high pressure resistant leakage-proof metal sealing clamp hoop locking type large diameter pipeline connecting device, belongs to the technical field of large diameter fluid-conveying pipeline connecting devices, and aims at solving the problems that an existing large diameter pipeline connecting equipment rubber sealing device is not resistant to high temperature, short in service life, unstable in sealing performance, poor in safety, high in maintenance cost, small in bearing pressure, harsh in installation requirement and not suitable for some occasions such as spacial gas and liquid seal. The high pressure resistant leakage-proof metal sealing clamp hoop locking type large diameter pipeline connecting device comprises a clamp hoop, bolts, two limiting rings and a sealing device composed of a sealing ring, the sealing ring is arranged in the middle of the sealing device, the limiting rings are arranged at the two ends of the sealing ring, and the sealing device is arranged in a groove in the middle of an inner cavity of the clamp hoop. The high pressure resistant leakage-proof metal sealing clamp hoop locking type large diameter pipeline connecting device has the advantages of being good in sealing effect, stable in sealing performance, long in service life, convenient to install and maintain, capable of being applied to the harsh environments such as high temperature, high pressure and special medium and strong in applicability for pipelines with different materials.

Owner:李俊伟

Boundary layer effect channel pushing engine for equipment

InactiveCN107084072AImprove utilization efficiencySmall diameterGas turbine plantsRam jet enginesRamjetCombustion chamber

The invention discloses a boundary layer effect channel propulsion engine for equipment, aiming to provide a motor capable of outputting high torque to replace current equipment vehicles, tanks, helicopters, ships and steam turbines, and mainly to realize equipment for fighter jets and missiles. scramjet engine. Its technical points are as follows: it includes a scramjet engine for equipped fighters and missiles consisting of a gas-propelled boundary layer effect channel rotor engine, a ramjet engine, and an air intake shroud. The described boundary layer effect channel rotor engine includes a boundary layer effect channel The rotor turbine is composed of multiple vortex-helical elongated channels and vortex-helical multi-layer superimposition. The rotor turbine is equipped with multiple superconducting heat pipes to cool and dissipate the turbine. The flame holder flame tube of the combustion chamber is distributed with multiple inclined inlets. The air channel constitutes the vortex flow combustion, and the ramjet engine includes a boundary layer effect channel rotor engine connected to drive a turbofan compressor, an inner and outer bypass, a combustion chamber, and the like.

Owner:刘国利

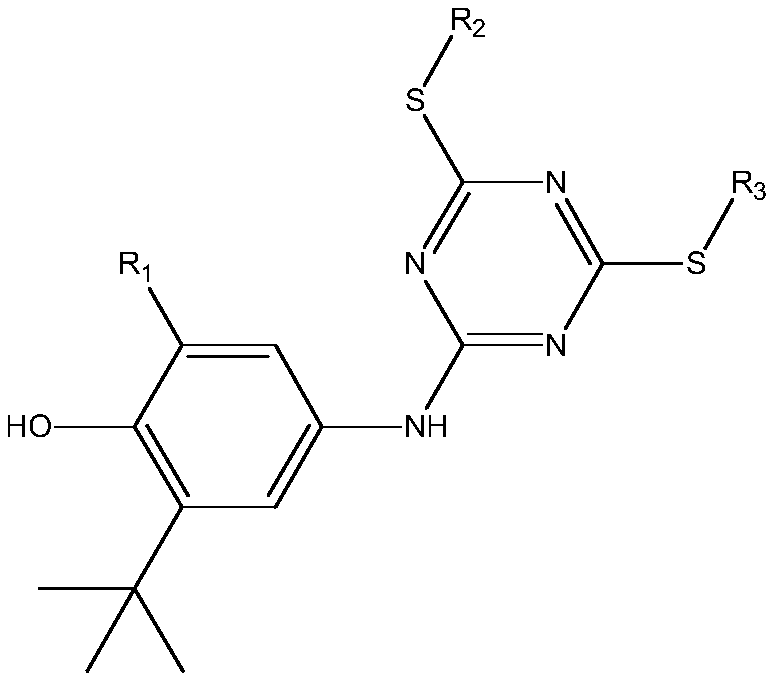

Lubricating oil additive composition

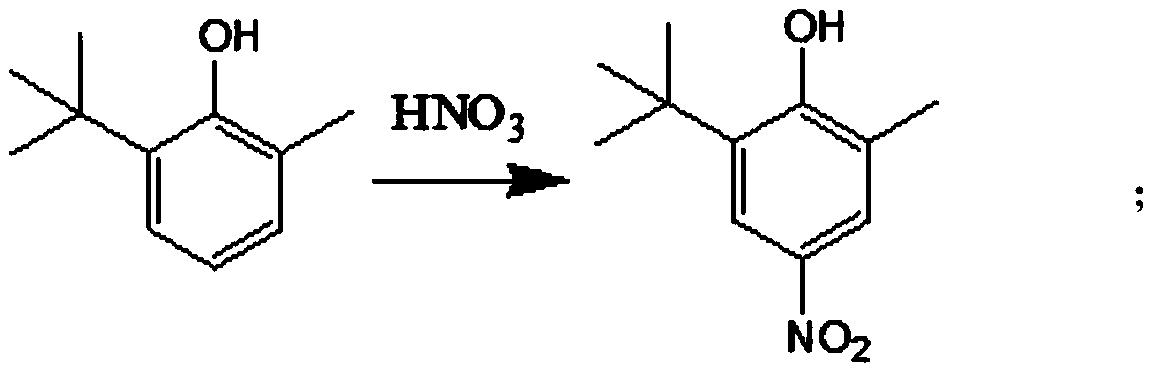

PendingCN111286386ASolve the problem of high temperature resistanceSolve problems prone to depositsAdditivesOil additivePhenolic antioxidant

The invention discloses a lubricating oil additive composition. The additive composition is prepared from the following components in percentage by mass: A, 20%-65% of a multifunctional antioxidant; B, 2.0%-6.5% of an antirust agent; C, 1.2%-3.5% of a metal deactivator; D, 2.0%-6.0% of a clearing agent; E, 1.0%-6.5% of a dispersing agent; and F, 25%-70% of an anti-wear agent, wherein the molecularstructural formula of the multifunctional antioxidant simultaneously contains multifunctional antioxidants of phenol, amine and sulfur, has double effects of a main antioxidant and an auxiliary antioxidant are realized, can generate intramolecular synergy, can be compounded with other antioxidants to generate a blending synergistic effect, so that the problems that phenolic antioxidants are not resistant to high temperature and amine antioxidants are easy to generate sediments can be solved, the thermal stability and the oxidation resistance of lubricating oil are improved, the generation ofsediments is reduced, the cleanness of the lubricating oil is improved, and the service life of the lubricating oil is prolonged.

Owner:玛可索(苏州)石化有限公司

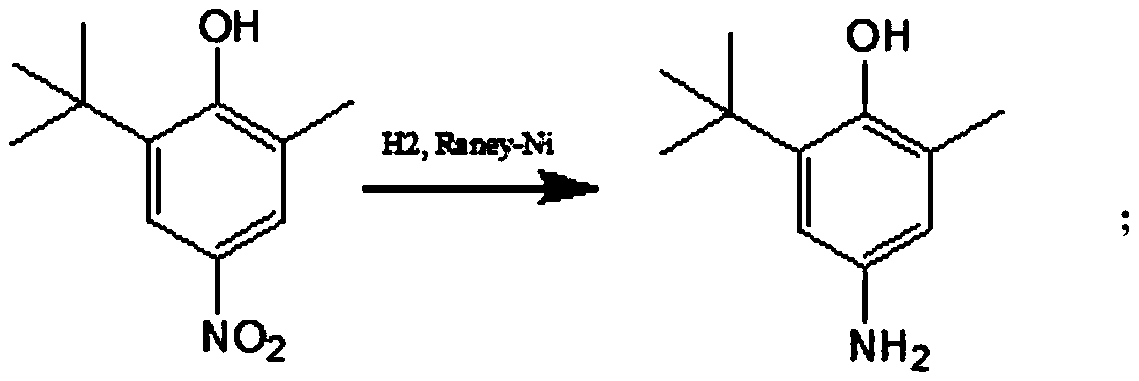

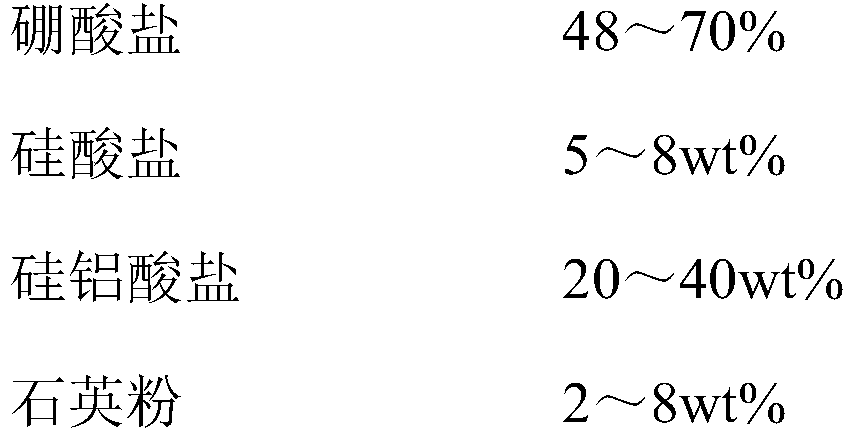

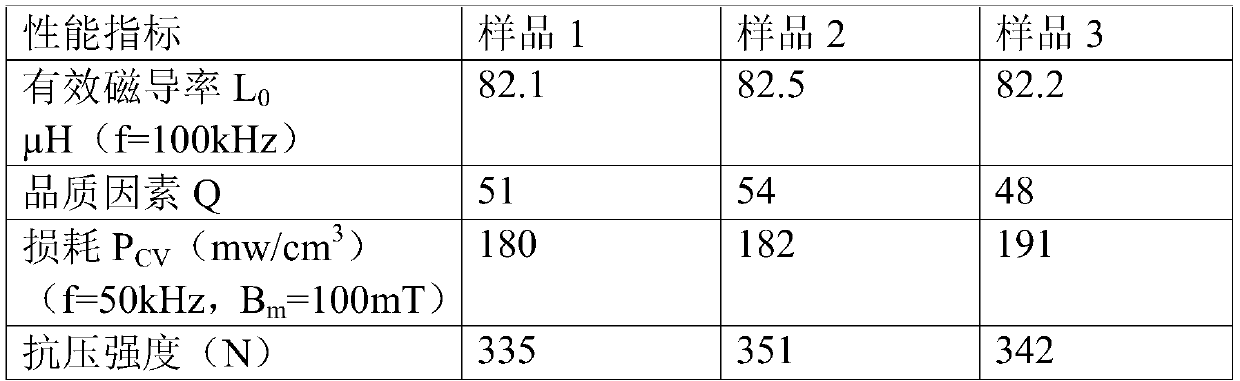

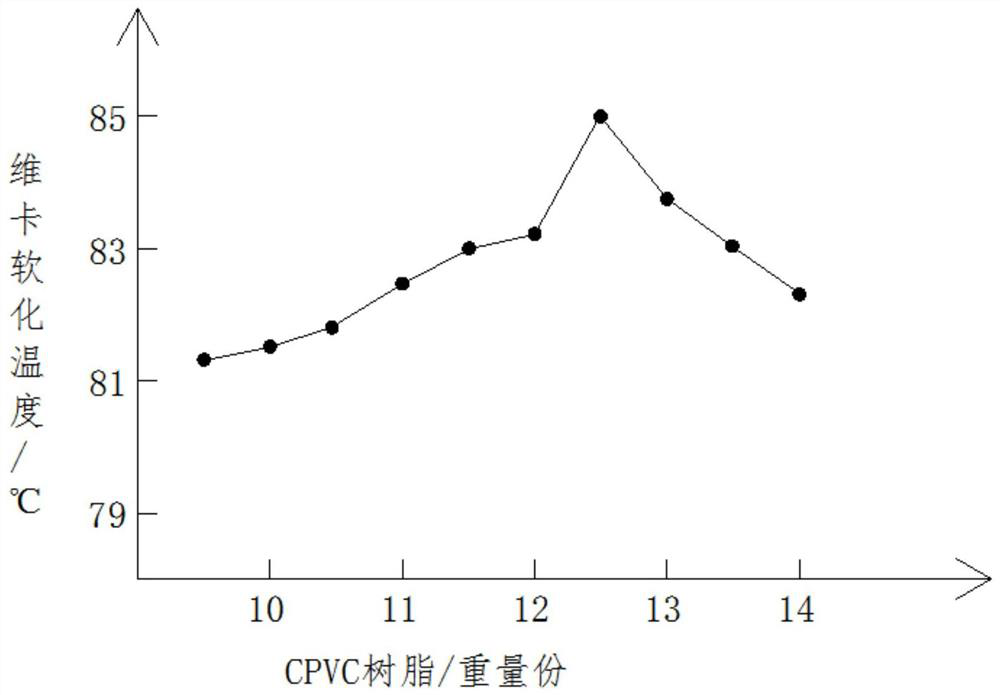

A kind of insulating all-inorganic adhesive for metal soft magnetic powder core and using method thereof

ActiveCN107845474BSolve the problem of high temperature resistanceOvercome the disadvantage of high lossInorganic material magnetismMass compositionPotassium

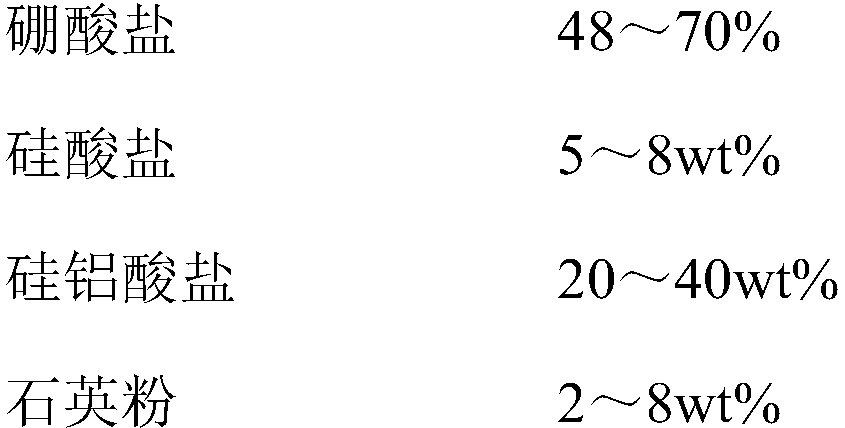

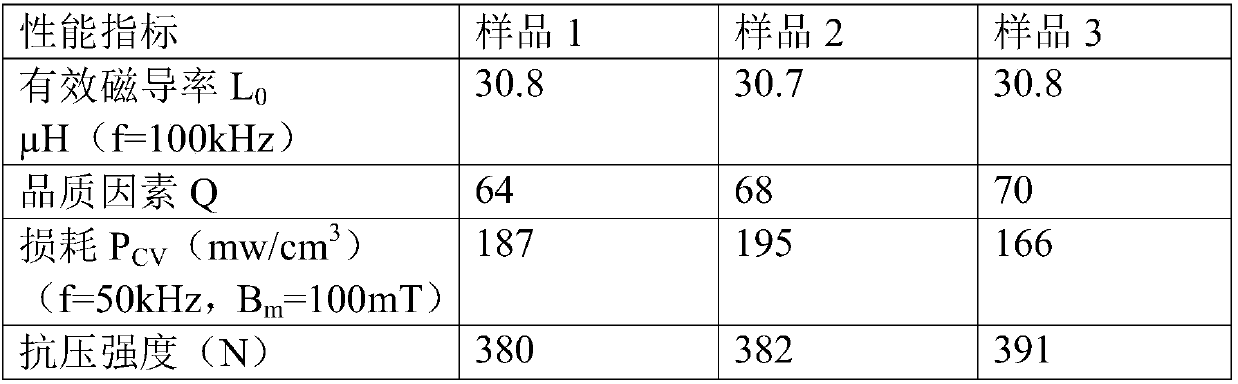

The invention discloses an insulating full inorganic binder for metal soft magnetic powder core and belongs to the technical field of magnetic material preparation. The insulating full inorganic binder is composed of borate, silicates, aluminosilicates and quartz; the mass compositions are: 48 to 70% borate, 5 to 8 wt% silicate, 20 to 40wt% aluminosilicates, 2 to 8 wt% quartz powder, wherein the borate is anhydrous sodium tetraborate powder; the silicate is sodium silicate powder; the aluminosilicates are two or more selected from talc, kaolin, albite, mica and potassium feldspar. The heat resistance temperature of the insulating full inorganic binder of the invention reaches 1000 DEG C; the invention can significantly improve the mechanical strength of the magnetic powder core, and the prepared magnetic powder core has comprehensive excellent magnetic properties and mechanical properties. The present invention is particularly suitable for iron-based magnetic powder cores and can significantly improve its high frequency performance and quality factors.

Owner:ANHUI UNIVERSITY OF TECHNOLOGY

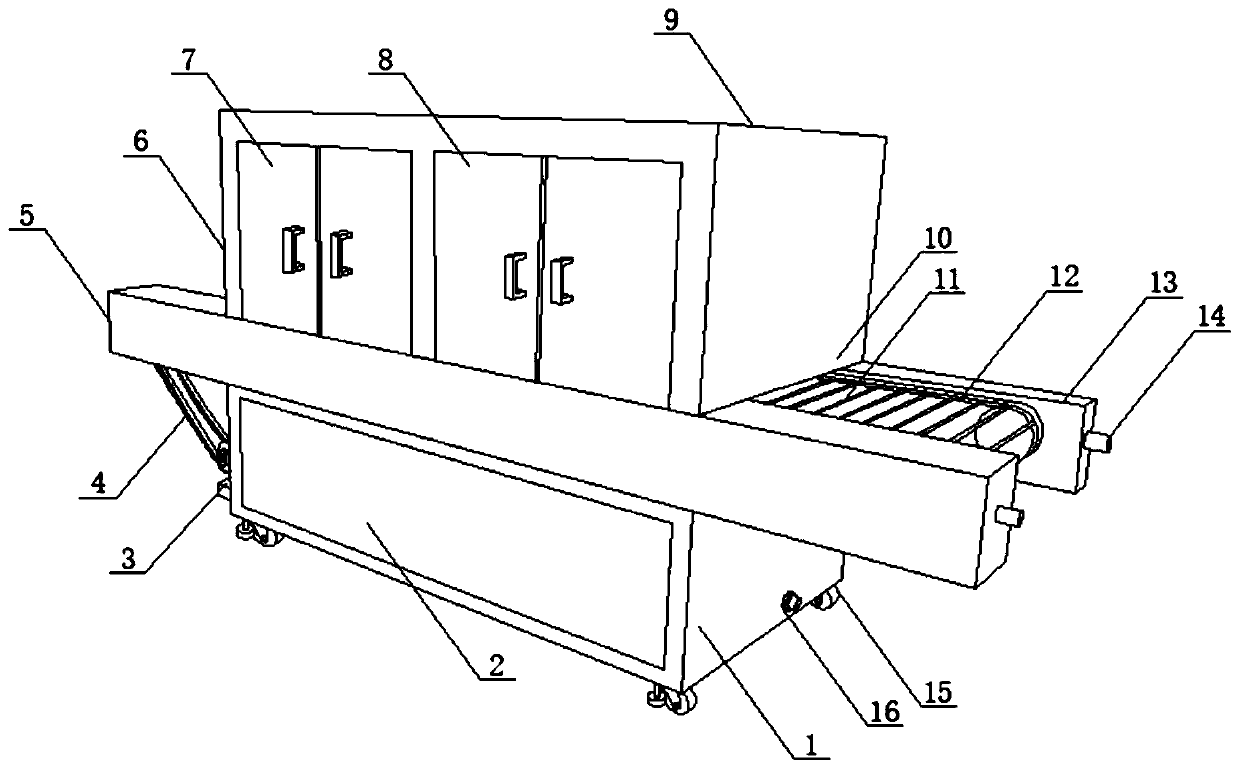

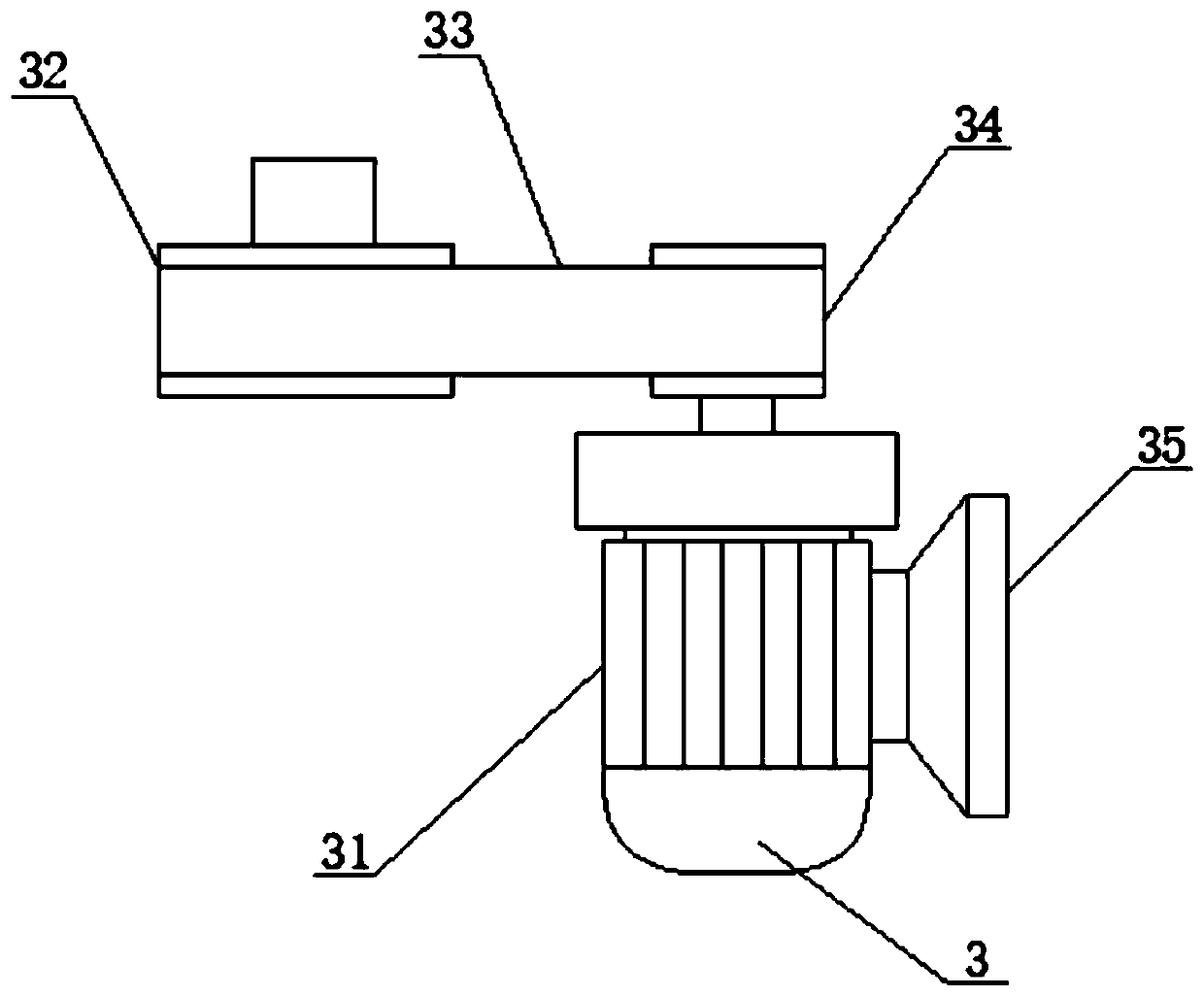

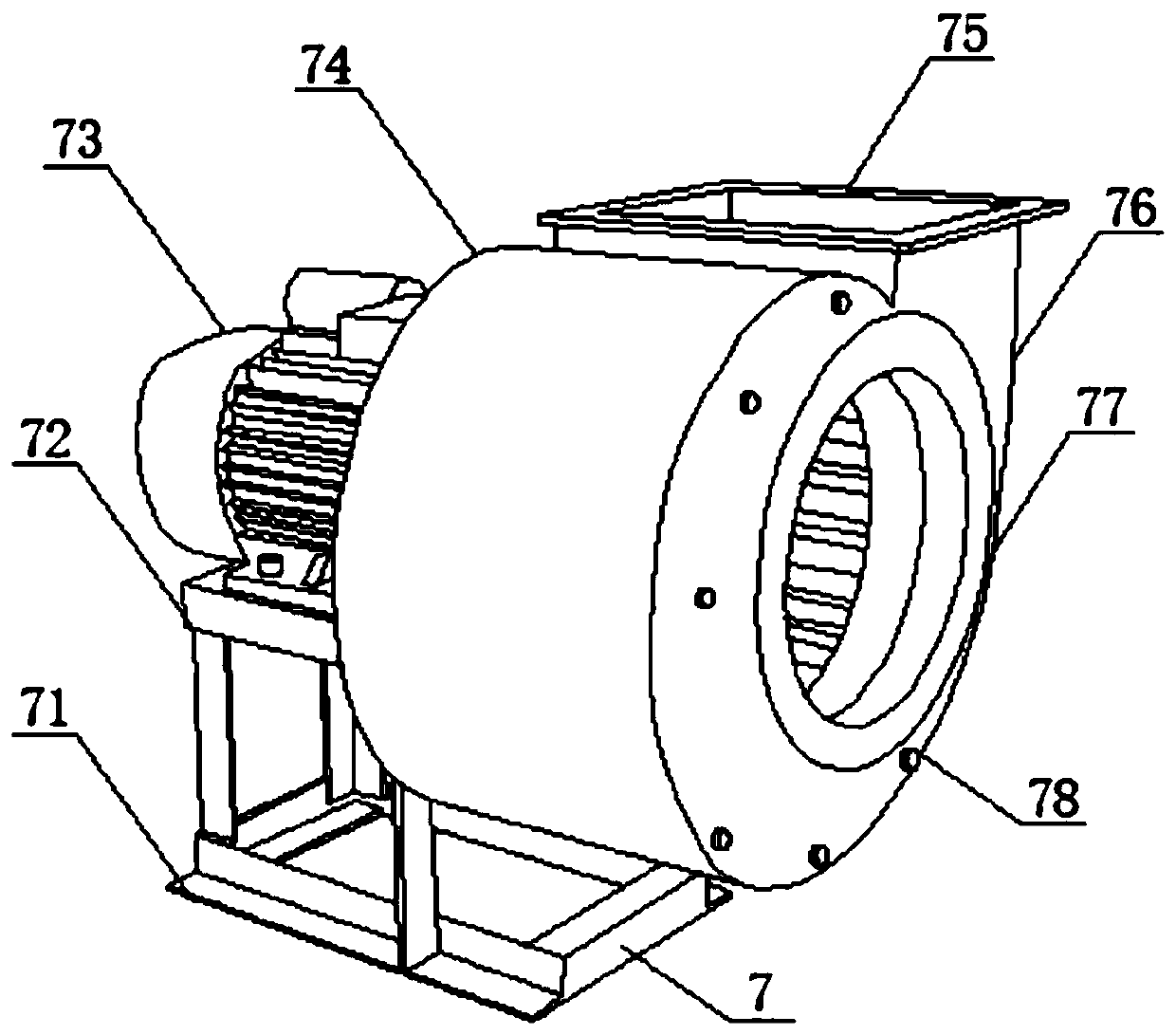

Dust removal equipment for spraying plastic products

PendingCN110227677ANoise mitigationSolve the problem of high temperature resistanceDrying gas arrangementsCleaning using liquidsMotor shaftEngineering

The invention discloses dust removal equipment for spraying plastic products. The dust removal equipment comprises a workbench and a cleaning box, wherein the cleaning box is arranged at the right endof the interior of the workbench, the cleaning box is fixedly connected to the right end of the lower side of the interior of the workbench through bolts, the workbench and the cleaning box are fixedly connected through the bolts, and a centrifugal fan box is arranged at the left end of the cleaning box. According to the dust removal equipment, a heat insulation seat is arranged at the joint of amotor shaft and a volute, the axial distance between a motor and the volute can be lengthened, and the problem that the torque is large after the motor shaft is lengthened is solved, so that the influence of high temperature generated by the volute on the motor can be isolated; a box body is arranged on the outer side of the centrifugal fan box, so that the noise generated by working of the motorthrough the volute can be further blocked when the motor works and operates, and the noise of the centrifugal fan box can be further relieved.

Owner:张家港市双友玻璃制品有限公司

A kind of preparation method of phytosterol ester

ActiveCN104402958BSolve the problem of high temperature resistanceImprove conversion rateOrganic-compounds/hydrides/coordination-complexes catalystsCatalytic reactionsPoly ether ether ketoneEvaporation

The invention relates to a preparation method for plant sterol ester. The method comprises the following steps: 1, stirring phytosterol and fatty acid under a vacuum condition in the presence of a high-temperature resistant polymer catalytic membrane, and heating the phytosterol and the fatty acid to be molten; 2, heating the phytosterol and the fatty acid to specified reaction temperature at constant speed, and performing thermostatic reaction; 3, separating a product mixture from the catalytic membrane after the reaction is ended; 4, adding alcohol for washing, performing stirring and standing demixing, and repeatedly washing a lower oil layer with alcohol; 5, performing vacuum rotary evaporation on the lower oil layer to obtain plant sterol ester after centrifugal demixing, wherein the high-temperature resistant polymer catalytic membrane is a polymer material of which the main chain is one of polyetheretherketone, poly-p-phenylene terephthamide, polyimide and polyaryletherketone and the side-chain radical is a catalytic active radical. According to the preparation method, the problems of corrosion to equipment, difficulty in product separation, environmental pollution, solid catalyst residues, high-temperature irresistance of cation exchange resin and more side reaction caused by reactant adsorption of resin micropores of homogeneous catalysis are solved.

Owner:江苏膜芮环保科技有限公司

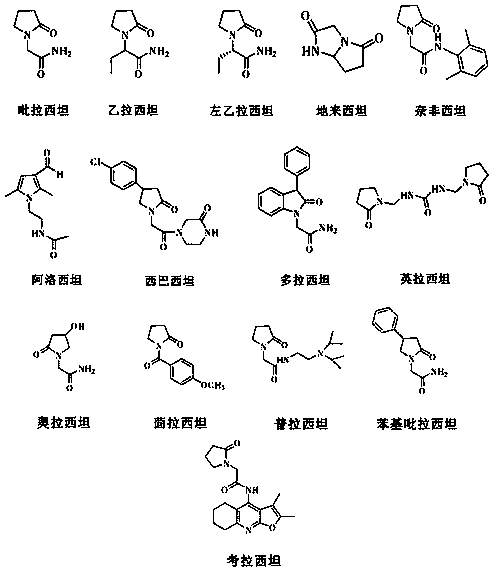

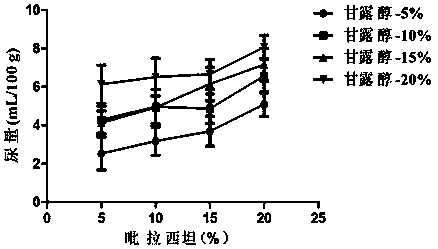

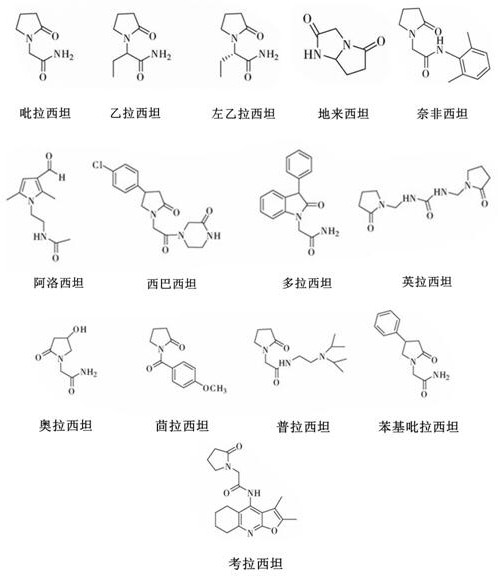

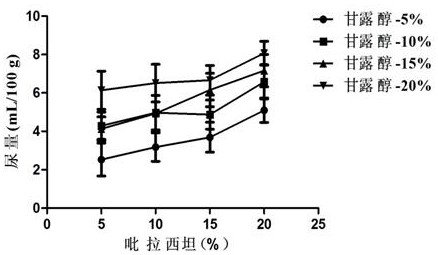

Racetam pharmaceutical composition containing buffering agent

ActiveCN107753481AInexpensive and safeSolve the problem of high temperature resistanceOrganic active ingredientsNervous disorderSodium acetateMANNITOL/SORBITOL

The invention belongs to the technical field of medicine, and relates to a racetam pharmaceutical composition containing buffering agent. The composition is prepared from the buffering agent, racetammedicine, mannitol and water, and is characterized in that the total massic volume percentage of racetam medicine and mannitol is 10-60% every 100 mL. The buffering agent is composite buffer salts ofone or two types of phosphate, acetate and citrate. The composition with addition of monosodium phosphate-dilute hydrochloric acid and sodium acetate-dilute hydrochloric acid has the optimal stability, the pH value of the buffering agent is 4.50-6.50, and the amount of the buffer salts is 0.5-1.0 mmol every 100 mL liquid. According to the racetam pharmaceutical composition containing the bufferingagent, through addition of the buffering agent into the composition, the stability is improved, the problem that the pH value and the relevant substance content of the racetam medicine significantlychange is solved, and the composition has broad application prospects.

Owner:SHENYANG PHARMA UNIVERSITY

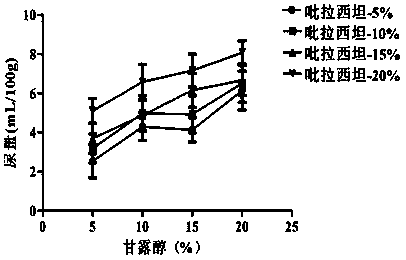

New formula for improving Vicat softening temperature of PVC building template

The invention discloses a novel formula for improving the vicat softening temperature of a PVC building template, relates to the technical field of building templates, and is prepared from the following components: 5-type PVC resin, plastic steel powder, light calcium powder, a stabilizer, CPVC resin, basalt glass fibers, a processing aid, white foam, yellow foam, a foam regulator, an inner lubricant, an outer lubricant and a high-temperature lubricant. According to the novel formula for increasing the Vicat softening temperature of the PVC building template, the mechanical property of the PVC building template is greatly improved by optimizing the formula components and the dosage of each component, and particularly the tensile property is greatly improved.

Owner:上海模新新材料科技有限公司

Insulating full inorganic binder for metal soft magnetic powder core and use method thereof

ActiveCN107845474AHigh strengthReduce eddy current lossInorganic material magnetismMass compositionPotassium

The invention discloses an insulating full inorganic binder for metal soft magnetic powder core and belongs to the technical field of magnetic material preparation. The insulating full inorganic binder is composed of borate, silicates, aluminosilicates and quartz; the mass compositions are: 48 to 70% borate, 5 to 8 wt% silicate, 20 to 40wt% aluminosilicates, 2 to 8 wt% quartz powder, wherein the borate is anhydrous sodium tetraborate powder; the silicate is sodium silicate powder; the aluminosilicates are two or more selected from talc, kaolin, albite, mica and potassium feldspar. The heat resistance temperature of the insulating full inorganic binder of the invention reaches 1000 DEG C; the invention can significantly improve the mechanical strength of the magnetic powder core, and the prepared magnetic powder core has comprehensive excellent magnetic properties and mechanical properties. The present invention is particularly suitable for iron-based magnetic powder cores and can significantly improve its high frequency performance and quality factors.

Owner:ANHUI UNIVERSITY OF TECHNOLOGY

N-doped crystalline silicon and preparation method thereof

InactiveCN101845666BUniform nitrogen dopingNitrogen doping concentration is easy to controlPolycrystalline material growthFrom frozen solutionsHigh concentrationDopant

The invention discloses a preparation method of an N-doped polysilicon ingot, which comprises the following steps that: the mixture of polysilicon material, silicon nitride nano powder with the grain size of 1 to 100nm and electrically active dopant is put into a quartz crucible and is loaded into a furnace; a furnace chamber is vacuumized and heated to 1420 to 1550DEG C, the temperature is insulated until the mixture is fully melted, to obtain molten silicon mixture; and then the molten silicon mixture is solidified to obtain the polysilicon ingot, wherein the electrically active dopant is any one type of B, P or Ga and the added amount makes the concentration of the electrically active dopant in the polysilicon ingot be 0.02 to 2ppm, and the added amount of the silicon nitride nano powder makes the nitrogen concentration in the polysilicon ingot be 0.0002 to 1ppm. The preparation method of N-doped polysilicon can dope nitrogen with existing equipment, and has the advantages of uniform nitrogen doping, high concentration of doped nitrogen, simple and easily controllable process and low cost. In addition, the invention also discloses a preparation method of an N-doped mono-crystalline ingot.

Owner:王敬 +1

A kind of preparation method of para-aramid fiber mica paper

ActiveCN105544286BHigh strengthImprove evennessInorganic fibres/flakesPhysical paper treatmentSlurryDielectric breakdown strength

The invention relates to a preparation method of para-aramid fiber mica paper. First, the para-aramid chopped fiber modified by a silane coupling agent is disentangled and dispersed to obtain slurry A; the beating degree is 40-65° The para-aramid fibrils of SR are screened to obtain slurry B; the mica sheet is modified with cationic starch solution to obtain modified mica sheet; the slurry A, slurry B and modified mica sheet are mixed evenly to obtain Mixed pulp, wherein, in terms of mass percentage, para-position chopped aramid fiber is 10-20%, para-aramid precipitated fiber is 20-40%, and mica sheet is 40-70%; the mixed pulp is sized and dehydrated Forming, pressing and drying, and then hot pressing to obtain para-aramid fiber mica paper. The para-aramid fiber mica paper prepared by the process of fiber screening and modification, wet papermaking, hot pressing and other processes has good paper evenness, excellent mechanical strength, dielectric breakdown strength and high temperature stability sex.

Owner:YANTAI METASTAR SPECIAL PAPER

Traditional Chinese medicine composition for treating piglet diarrhea and preparation method thereof

PendingCN114522214AImprove diarrhea symptomsImprove immunityPowder deliveryFood processingBiotechnologyVeterinary Drugs

The invention discloses a traditional Chinese medicine composition for treating piglet diarrhea and a preparation method of the traditional Chinese medicine composition, belongs to the technical field of veterinary medicines, and aims to solve the problems that existing antibiotic medicines are easy to generate drug resistance and existing traditional Chinese medicines are single in treatment disease. The traditional Chinese medicine composition comprises the following raw materials: codonopsis pilosula, astragalus membranaceus, coptis chinensis, scutellaria baicalensis, turmeric, clove, pokeberry root, phoenix-tail fern, medicated leaven, fried coix seed, fructus psoraleae, purslane, dandelion and liquorice. The preparation method comprises the following steps: crushing the raw materials into particles, mixing codonopsis pilosula, astragalus membranaceus, dandelion, coptis chinensis, radix scutellariae, fried coix seeds, fructus psoraleae and purslane according to the formula amount, and carrying out a reflux extraction method; mixing the other raw materials according to the formula amount, and extracting by a decoction method; and mixing the extracting solutions, concentrating to obtain an extract, adding auxiliary materials in an equal amount, grinding, sieving, and drying to obtain the traditional Chinese medicine composition. The traditional Chinese medicine composition disclosed by the invention can be used for replacing antibiotic medicines, is effective for diarrhea of piglets caused by various reasons, and can be used for effectively improving the immunity of the piglets.

Owner:河南百动康生物科技有限公司

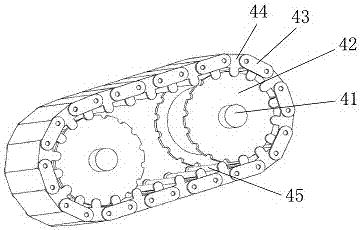

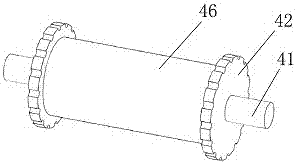

High-temperature-resistant conveyor for chemical raw materials

InactiveCN107098113AImprove high temperature resistanceSolve the problem of high temperature resistanceConveyorsPackagingCouplingDrive shaft

Owner:XIANGZHOU COUNTY INST OF SCI & TECHN INFORMATION

Method for preparing nano ITO powder at low temperature

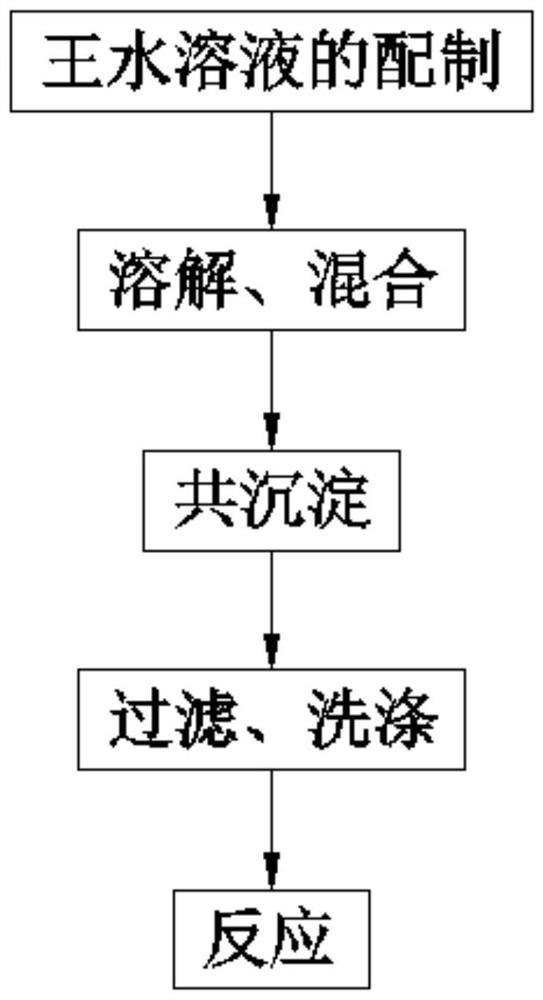

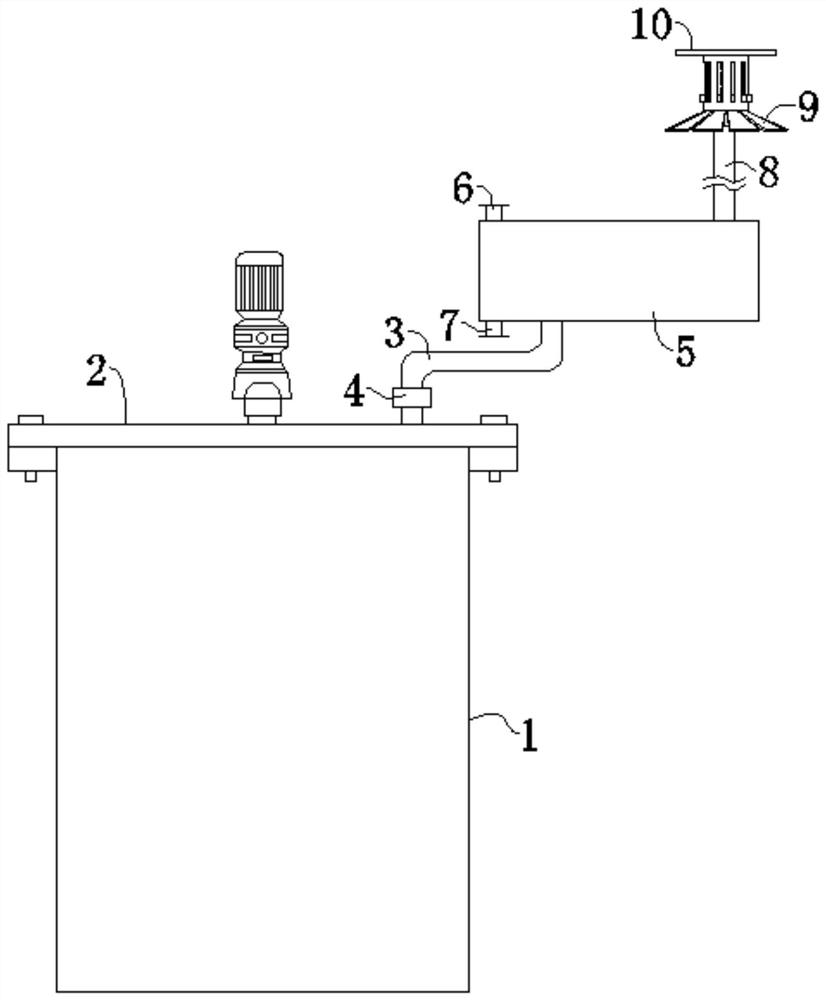

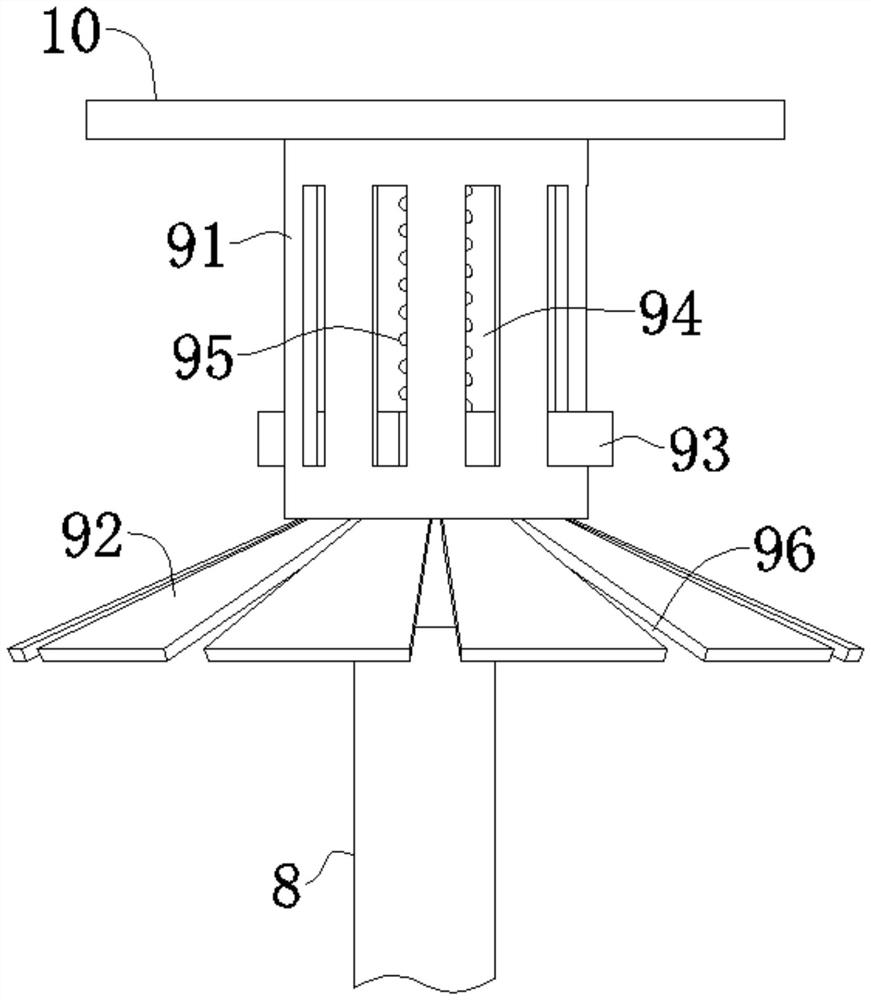

The invention discloses a method for preparing nano ITO powder at low temperature, and belongs to the technical field of nano ITO powder processing. The method comprises the following steps of S1, preparation of an aqua regia solution: using concentrated hydrochloric acid and concentrated nitric acid to prepare the aqua regia solution according to the volume ratio of 1:3; S2, dissolving and mixing: taking 40 ml of aqua regia solution, then weighing 10-20 g of metal indium and 3-5 g of tin tetrachloride, sequentially dissolving the metal indium and the tin tetrachloride in the aqua regia solution, and uniformly conducting stirring for later use to obtain a mixture; S3, co-precipitation: adding a sodium hydroxide solution into the mixture obtained in the step S2 while stirring, and carrying out co-precipitation on the sodium hydroxide solution and the mixture to obtain a colloid precursor of indium hydroxide and tin hydroxide; S4, filtering and washing: washing the colloid precursor obtained in the step S3 with distilled water for 2-4 times to obtain indium tin hydroxide; and S5, reaction. The invention solves the problem that an existing hydrothermal preparation process has high requirement on temperature resistance of equipment.

Owner:株洲火炬安泰新材料有限公司

A kind of racetam pharmaceutical composition containing buffer

ActiveCN107753481BInexpensive and safeSolve the problem of high temperature resistanceOrganic active ingredientsNervous disorderSodium acetateP phosphate

The invention belongs to the technical field of medicine, and relates to a racetam pharmaceutical composition containing buffering agent. The composition is prepared from the buffering agent, racetammedicine, mannitol and water, and is characterized in that the total massic volume percentage of racetam medicine and mannitol is 10-60% every 100 mL. The buffering agent is composite buffer salts ofone or two types of phosphate, acetate and citrate. The composition with addition of monosodium phosphate-dilute hydrochloric acid and sodium acetate-dilute hydrochloric acid has the optimal stability, the pH value of the buffering agent is 4.50-6.50, and the amount of the buffer salts is 0.5-1.0 mmol every 100 mL liquid. According to the racetam pharmaceutical composition containing the bufferingagent, through addition of the buffering agent into the composition, the stability is improved, the problem that the pH value and the relevant substance content of the racetam medicine significantlychange is solved, and the composition has broad application prospects.

Owner:SHENYANG PHARMA UNIVERSITY

Oil resistant silicone rubber

The invention provides an oil-resistant silicon rubber composition. The composition comprises the following components in parts by weight: (a) crude methylvinyl silicon rubber including 71+ / -2 parts of methylvinyl silicon rubber containing 0.07-0.09 percent of vinyl and 29+ / -2 parts of methylvinyl silicon rubber containing 0.15-0.17 percent of vinyl, wherein the number average molecular weights of the two types of rubber are 580,000-620,000, (b) 2.2+ / -0.5 parts of hydroxyl silicon oil, (c) 1.4+ / -0.2 parts of hydrogen-containing silicon oil and (d) an oil-resistant component including 42+ / -10 parts of white carbon black which is precipitated white carbon black, 1.1+ / -0.2 parts of dimethyl silicon oil of which the polymerization degree is between 150 and 300, 9+ / -2 parts of pot clay of 3000+ / -500 meshes, and 5+ / -0.5 parts of polytetrafluoroethylene, wherein the total weight of the components (a), (b), (c) and (d) accounts for 90-100 percent of the total weight of the composition. The invention further provides oil-resistant silicon rubber and a preparation method and an application thereof.

Owner:上海旭创高分子材料有限公司

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com