A kind of preparation method of para-aramid fiber mica paper

A technology of para-aramid fiber and para-aramid fiber, which is applied in the directions of synthetic cellulose/non-cellulose material pulp/paper, fiber raw material processing, inorganic fiber/sheet, etc., which can solve the problem of difficulty in reaching C-class insulation grade and above. Material requirements, difficulty in meeting high-end applications, limited heat resistance of meta-aramid fibers, etc., to achieve excellent liquid phase dispersion properties and composite reinforcement effects, major market prospects and practical significance, and excellent mechanical strength.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

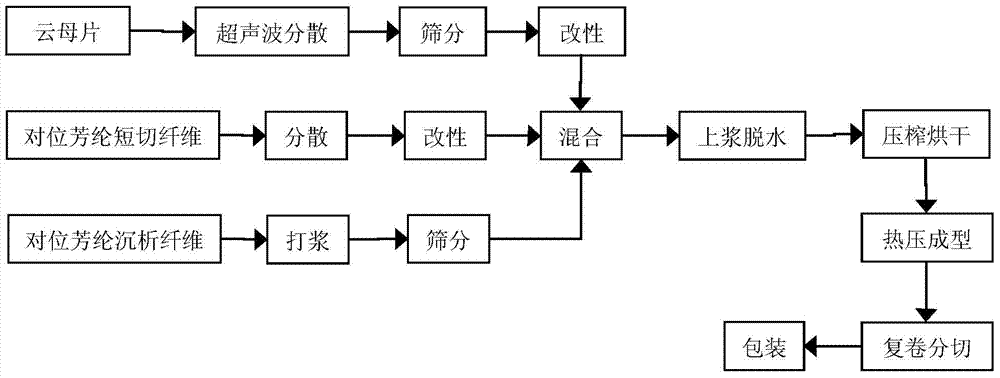

Method used

Image

Examples

Embodiment 1

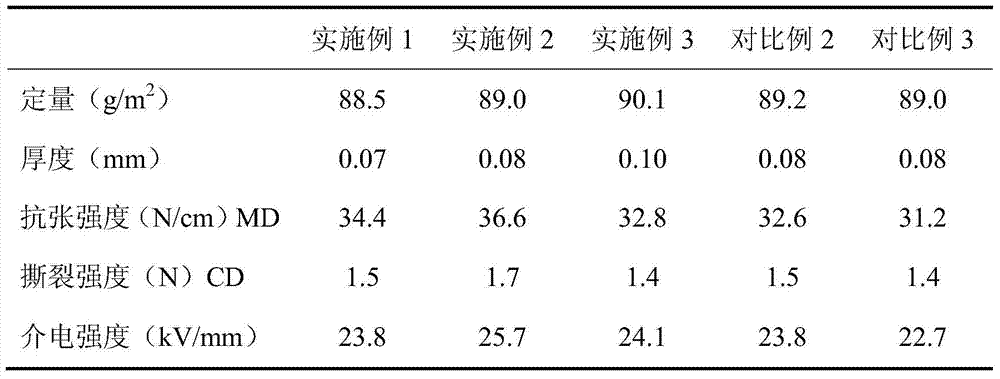

[0033] Example 1 Preparation of para-aramid fiber mica paper by the method of the present invention

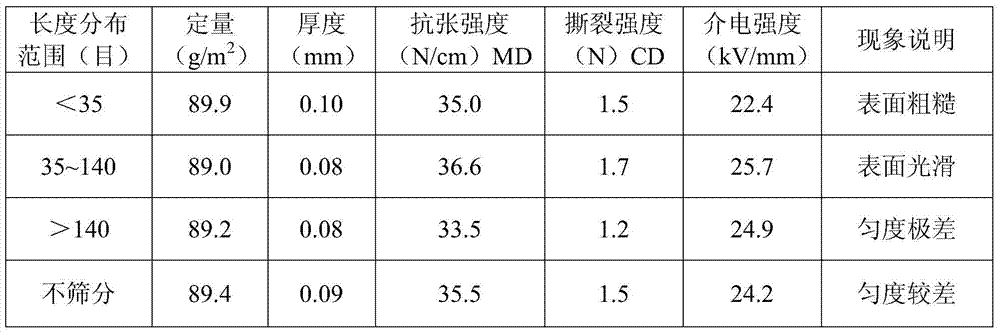

[0034]Ultrasonic treatment is used to peel the muscovite flakes into mica flakes, the power is 800W, and the time is 10h. The particle size of the mica flakes is classified by a sieve, according to the particle size ratio of ≦20 mesh: 20-40 mesh: ≧40 mesh = Combine at a ratio of 1:6:3, then modify with cationic starch, the mass concentration of cationic starch is 0.01%, the modification time is 60min, the concentration of modified mica slurry is 10%, and the modified mica sheet is obtained after washing. ; Use silane coupling agent to modify the para-aramid chopped fiber with a length of 12mm and a fineness of 1.5D, the mass concentration of the coupling agent is 3%, and the consumption is 0.1% of the dry mass of the relative para-aramid chopped fiber, The modification time was 10 hours, fully decomposed and dispersed, and a slurry A with a mass concentration of 0.01% was prep...

Embodiment 2

[0035] Example 2 Preparation of para-aramid fiber mica paper by the method of the present invention

[0036] Ultrasonic treatment is used to peel mica flakes into mica flakes. The power is 1500W, and the time is 5h. The particle size classification of mica flakes is carried out by a sieving instrument. Combine at a ratio of 2:5:3, and then modify with cationic starch, the mass concentration of cationic starch is 0.05%, the modification time is 30min, the concentration of modified mica slurry is 16%, and the modified mica sheet is obtained by washing after modification; Use a silane coupling agent to modify para-aramid chopped fibers with a length of 12mm and a fineness of 1.5D. The mass concentration of the coupling agent is 5%, the modification time is 5h, and the dosage is 0.5% of the absolute dry mass of the chopped fibers. Fully deconcentrate and disperse to obtain a slurry A with a mass concentration of 0.02%; pass the aramid precipitated fiber with a beating degree of 50...

Embodiment 3

[0037] Example 3 Preparation of para-aramid fiber mica paper by the method of the present invention

[0038] Ultrasonic treatment is used to peel off mica flakes into mica flakes. The power is 3000W and the time is 1h. The particle size classification of mica flakes is carried out by a sieving instrument. Combine at a ratio of 3:4:3, and then modify with cationic starch, the mass concentration of cationic starch is 0.1%, the modification time is 10 minutes, the concentration of modified mica slurry is 20%, and the modified mica sheet is obtained by washing after modification; Use a silane coupling agent to modify para-aramid chopped fibers with a length of 12mm and a fineness of 1.5D. The mass concentration of the coupling agent is 10%, the modification time is 1h, and the dosage is 1% of the absolute dry mass of the chopped fibers. Fully deconcentrate and disperse to obtain a slurry A with a mass concentration of 0.05%; pass the aramid precipitated fiber with a beating degree...

PUM

| Property | Measurement | Unit |

|---|---|---|

| length | aaaaa | aaaaa |

| dielectric strength | aaaaa | aaaaa |

| heat deflection temperature | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com