High-temperature-resistant conveyor for chemical raw materials

A technology of chemical raw materials and conveyors, which is applied in the directions of conveyors, transportation, packaging, packaging, etc., can solve the problems of high temperature resistance of conveyors, solve the problem of high temperature resistance, save time and labor, and have strong maneuverability. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0013] The present invention will be further described below in conjunction with specific drawings and embodiments.

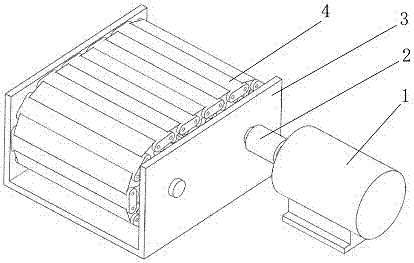

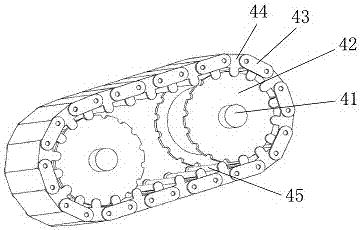

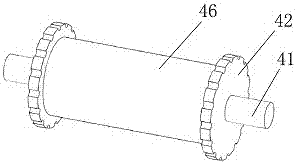

[0014] Such as Figure 1-3 As shown, the present invention mainly includes sprocket 42, first chain link 43, second chain link 44, chain cylinder 45, drive shaft 41, sleeve 46, motor 1 used as power, shaft coupling for transmitting torque 2. It is characterized in that: the conveyor 4 composed of sprocket 42, first chain link 43, second chain link 44, chain barrel 45, transmission shaft 41, and sleeve 46, the transmission shaft 41 is installed on the mounting base 3 through bearings , the motor 1 is connected to the transmission shaft 41 through the coupling 2, and the shaft system on the transmission shaft 41 cooperates and fixedly installs two sprockets 42, and the two sprockets 42 are positioned and separated by a sleeve 46, and the first chain link 43 and The second chain links 44 are hinged to form a chain, and the sprocket wheel 42 meshes with the chain ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com