Boundary layer effect channel pushing engine for equipment

A boundary layer and engine technology, which is applied in the direction of machines/engines, ramjet engines, mechanical equipment, etc., can solve the problems of high difficulty in manufacturing the turntable structure, small output torque of the turbine, and obstruction of gas thrust, so as to improve fuel consumption. Economical, high utilization efficiency, and small effect resistance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0050] Preferred embodiments of the present invention will be described in detail below in conjunction with the accompanying drawings.

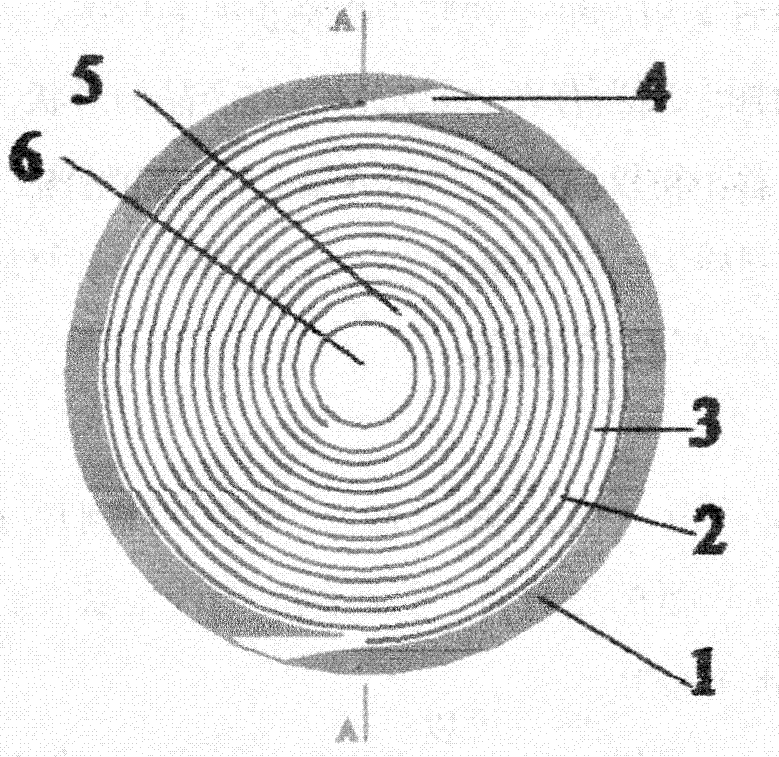

[0051] see figure 1 As shown in the embodiment therein, in the rotor formed by the boundary layer effect channel 3 of the two-headed helix 2 in the circular housing 1, the fluid enters through the air inlet 4 and flows through the boundary layer effect channel to generate shear. The shearing force pushes the rotor to rotate, and the fluid is finally discharged from the exhaust port of the channel, and the power output shaft position 6 in the center is provided with a power output shaft.

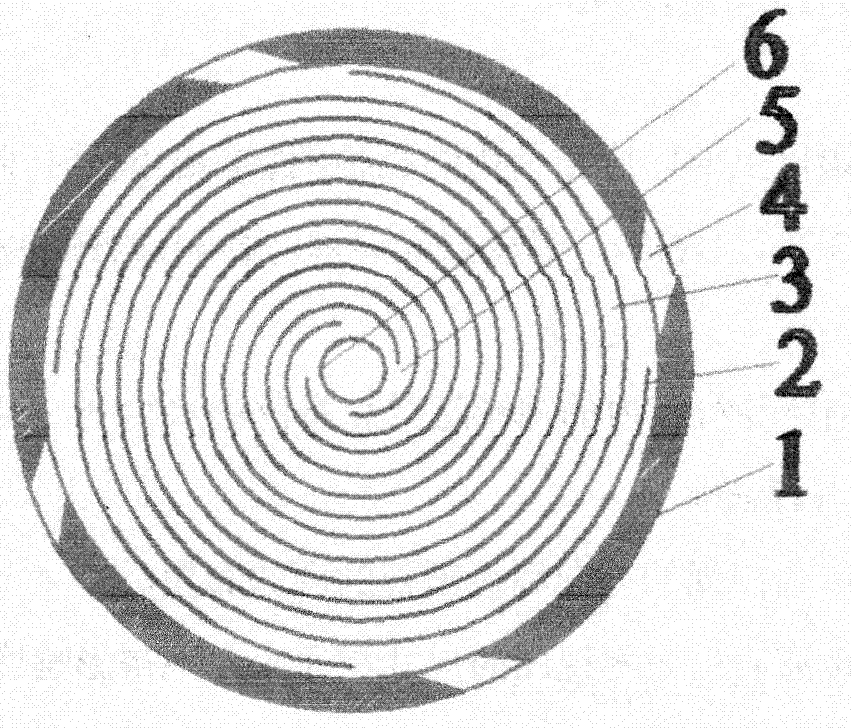

[0052] join figure 2 Among them, the rotor is composed of four helical bodies 2, the air consumption and output torque are increased, and the helical body 2 can be provided with a multi-head structure.

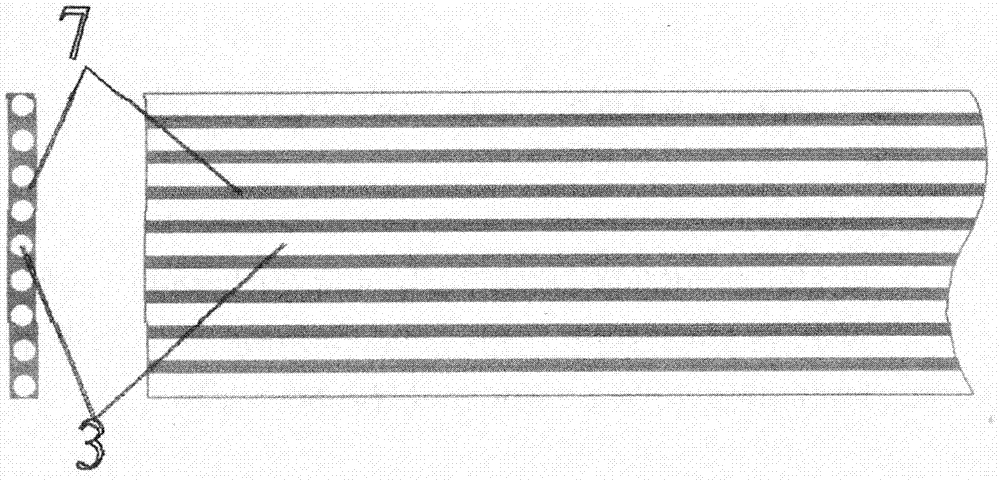

[0053] image 3 , Figure 4 , Figure 5 , Figure 24 As shown, a plurality of narrow tubes or corrugated tubes with boundary layer effect channels ar...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com