New formula for improving Vicat softening temperature of PVC building template

A technology of Vicat softening temperature and building formwork, applied in the field of building formwork, can solve problems such as unsatisfactory, achieve the effects of improving mechanical properties, expanding application range, and improving heat resistance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

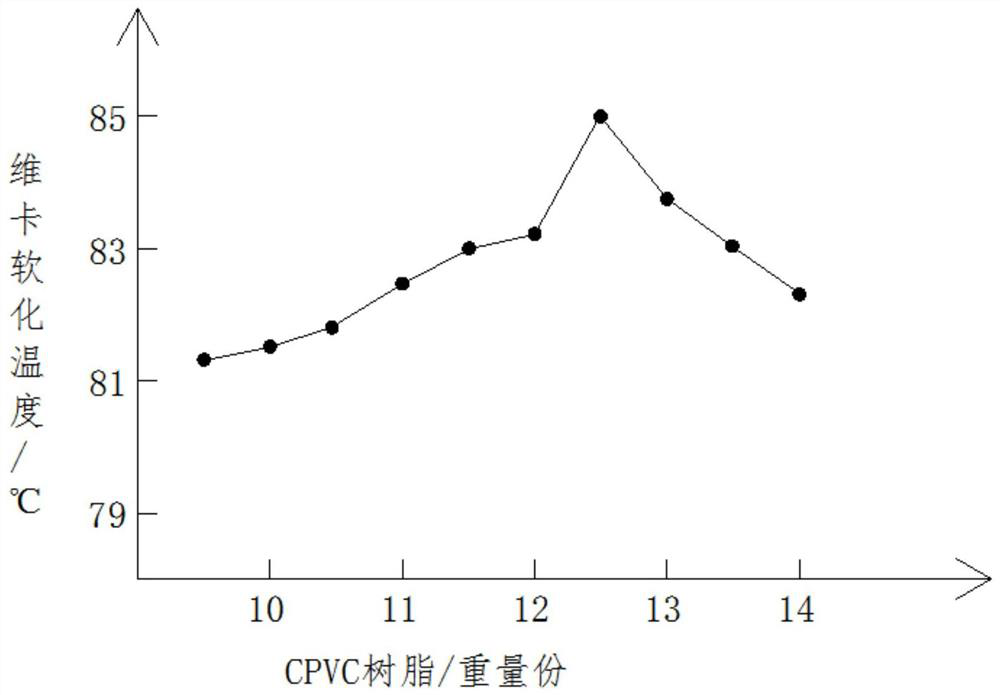

[0046] A new formula for improving the Vicat softening temperature of PVC building formwork, which is made of the following ingredients in parts by weight: 75 parts of type 5 PVC resin, 65 parts of plastic steel powder, 25 parts of light calcium powder, 2.39 parts of stabilizer, CPVC resin 12.5 parts, 9 parts of basalt glass fiber, 4 parts of processing aid, 0.9 part of white foam, 0.4 part of yellow foam, 6.5 parts of foam regulator, 0.56 part of internal lubrication, 0.75 part of external lubrication, and 0.15 part of high temperature lubrication. The stabilizer is a composite lead salt stabilizer. The basalt glass fiber is formed by melting basalt rock at 1488°C and then drawing it with a platinum-rhodium alloy drawing bushing. The white foam is sodium bicarbonate. The yellow foam is azodicarbonamide. The foaming regulator is an acrylic foaming regulator; the processing aid is an acrylic processing aid. The internal lubrication is zinc stearate; the external lubrication ...

Embodiment 2

[0054] A new formula for improving the Vicat softening temperature of PVC building formwork, which is made of the following ingredients in parts by weight: 75 parts of type 5 PVC resin, 66 parts of plastic steel powder, 26 parts of light calcium powder, 3 parts of stabilizer, CPVC resin 13 parts, 10 parts of basalt glass fiber, 5 parts of processing aid, 1 part of white foam, 0.4 part of yellow foam, 7 parts of foam regulator, 0.6 part of internal lubrication, 0.8 part of external lubrication, and 0.1 part of high temperature lubrication. The stabilizer is a composite lead salt stabilizer. The basalt glass fiber is formed by melting basalt rock at 1488°C and then drawing it with a platinum-rhodium alloy drawing bushing. The white foam is sodium bicarbonate. The yellow foam is azodicarbonamide. The foaming regulator is an acrylic foaming regulator; the processing aid is an acrylic processing aid. The internal lubrication is zinc stearate; the external lubrication is polyethy...

Embodiment 3

[0062] A new formula for improving the Vicat softening temperature of PVC building formwork, which is made of the following ingredients in parts by weight: 75 parts of type 5 PVC resin, 66 parts of plastic steel powder, 24.2 parts of light calcium powder, 3 parts of stabilizer, CPVC resin 12.3 parts, 8.7 parts of basalt glass fiber, 4.7 parts of processing aids, 0.93 parts of white foam, 0.48 parts of yellow foam, 6.1 parts of foam regulator, 0.57 parts of internal lubrication, 0.72 parts of external lubrication, and 0.12 parts of high-temperature lubrication. The stabilizer is a composite lead salt stabilizer. The basalt glass fiber is formed by melting basalt rock at 1488°C and then drawing it with a platinum-rhodium alloy drawing bushing. The white foam is sodium bicarbonate. The yellow foam is azodicarbonamide. The foaming regulator is an acrylic foaming regulator; the processing aid is an acrylic processing aid. The internal lubrication is zinc stearate; the external l...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com