Method for preparing nano ITO powder at low temperature

A nano-powder technology, applied in the field of low-temperature preparation of nano-ITO powder, can solve the problem of high temperature resistance of equipment, achieve soft reaction conditions, high temperature resistance of equipment, and good crystallization status

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

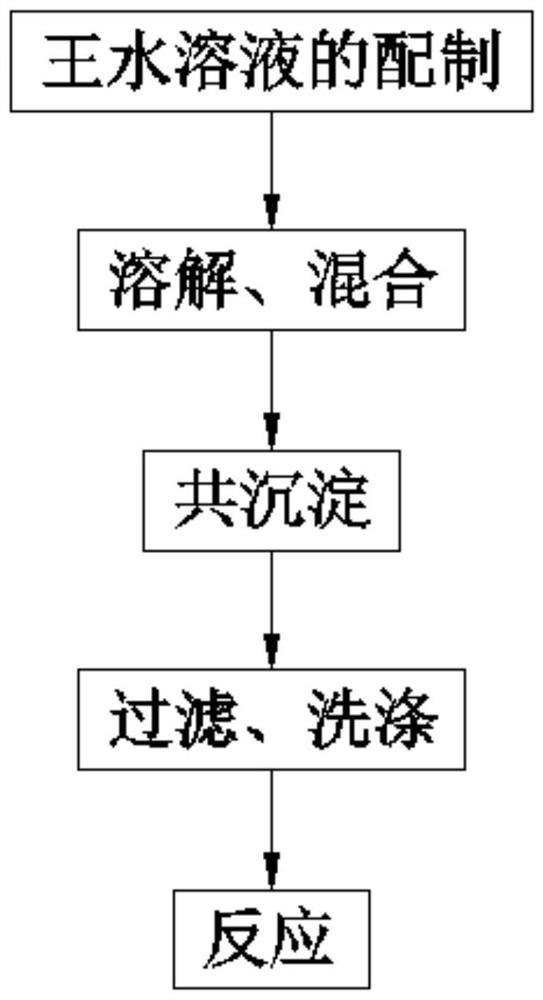

[0042] Embodiment 1: a kind of method for preparing nano-ITO powder at low temperature, such as figure 1 shown, including the following steps:

[0043] S1, preparation of aqua regia solution

[0044] Concentrated hydrochloric acid and concentrated nitric acid are made into 80ml of aqua regia solution at a volume ratio of 1:3;

[0045] S2, dissolve, mix

[0046] Take 40ml of aqua regia solution, then weigh 16g of metal indium (99.99%) and 3.4g of tin tetrachloride to dissolve them in the aqua regia solution in turn, stir evenly, set aside to obtain In 2 o 3 : SnO 2 A mixture with a weight ratio of 9:1;

[0047] S3, coprecipitation

[0048] Under stirring, sodium hydroxide solution is added to the mixture obtained in step S2, so that the mixture is neutral, and after the two co-precipitate, the colloidal precursor of indium hydroxide and tin hydroxide is obtained;

[0049] S4, filter, wash

[0050] Wash the colloidal precursor obtained in step S3 with distilled water for...

Embodiment 2

[0067] Embodiment 2: a kind of method for preparing nano-ITO powder at low temperature, the difference with embodiment 1 is, comprises the following steps:

[0068] S1, preparation of aqua regia solution

[0069] Concentrated hydrochloric acid and concentrated nitric acid are made into 80ml of aqua regia solution at a volume ratio of 1:3;

[0070] S2, dissolve, mix

[0071] Take 40ml of aqua regia solution, then weigh 10g of metal indium (99.99%) and 3g of tin tetrachloride to dissolve them in the aqua regia solution in turn, stir evenly, set aside to obtain In 2 o 3 : SnO 2 A mixture with a weight ratio of 8:1;

[0072] S3, coprecipitation

[0073] Under stirring, sodium hydroxide solution is added to the mixture obtained in step S2, so that the mixture is neutral, and after the two co-precipitate, the colloidal precursor of indium hydroxide and tin hydroxide is obtained;

[0074] S4, filter, wash

[0075] Wash the colloidal precursor obtained in step S3 with distilled...

Embodiment 3

[0078] Embodiment 3: a kind of method for preparing nano-ITO powder at low temperature, the difference with embodiment 1 is, comprises the following steps:

[0079] S1, preparation of aqua regia solution

[0080] Concentrated hydrochloric acid and concentrated nitric acid are made into 80ml of aqua regia solution at a volume ratio of 1:3;

[0081] S2, dissolve, mix

[0082] Take 40ml of aqua regia solution, then weigh 10g of metal indium (99.99%) and 3g of tin tetrachloride to dissolve them in the aqua regia solution in turn, stir evenly, set aside to obtain In 2 o 3 : SnO 2 A mixture with a weight ratio of 8:1;

[0083] S3, coprecipitation

[0084] Under stirring, sodium hydroxide solution is added to the mixture obtained in step S2, so that the mixture is neutral, and after the two co-precipitate, the colloidal precursor of indium hydroxide and tin hydroxide is obtained;

[0085] S4, filter, wash

[0086] Wash the colloidal precursor obtained in step S3 with distilled...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com