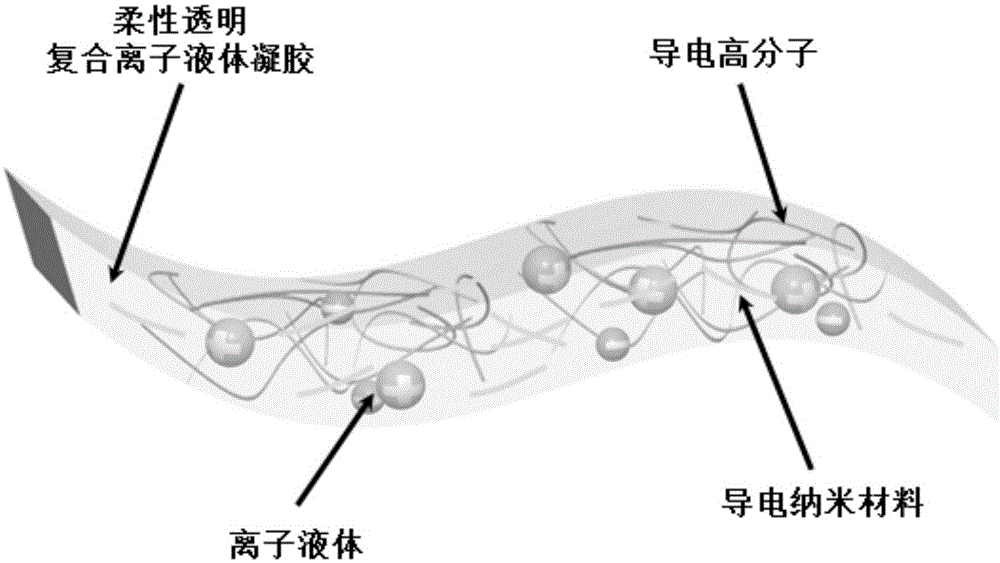

Preparation method for flexible and transparent composite ionic liquid gel conductive electrode

A technology of transparent conductive electrodes and composite ions, which is applied in semiconductor/solid-state device manufacturing, circuits, photovoltaic power generation, etc., can solve the problems of complex preparation process of silver nanowires, high process cost, and reduced conductivity, so as to achieve stable properties and equipment Simple, easy-to-use effects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0032] (1) Preparation method of transparent porous polymer network

[0033] The monomer acrylamide, the initiator potassium persulfate, the crosslinking agent N,N-methylenebisacrylamide, and the porogen sodium bicarbonate are dissolved in water at a weight ratio of 1000 / 10 / 30 / 5 by weight (acrylamide / The weight ratio of water is 150 / 1000), stir to a uniform state. Then, it reacts to form a gel under heating at 80°C, and is soaked in an acidic solution of pH=5 to remove sodium bicarbonate to obtain a transparent porous polymer gel. This type of porous gel is used in the next step to prepare an ionic liquid gel transparent electrode.

[0034] (2) Preparation method of composite ionic liquid gel transparent electrode with enhanced mechanical properties

[0035] The transparent porous polymer gel formed in step (1) is immersed in an aqueous solution containing 1-vinyl-3-ethylimidazole dinitrile amine salt, potassium persulfate, and N,N-methylenebisacrylamide (1 -The weight ratio of vi...

Embodiment 2

[0041] (1) Preparation method of transparent porous polymer network

[0042] Monomer methyl methacrylate, initiator benzophenone, cross-linking agent polyethylene glycol dimethacrylate, porogen polyethylene glycol (molecular weight 600) in a weight ratio of 1000 / 20 / 20 / 10 The ratio is dissolved in acetone (the weight ratio of methyl methacrylate / acetone is 200 / 1000), and stirred to a uniform state. Then, it reacts to form a gel under 255nm ultraviolet light irradiation, and is soaked in acetone to remove polyethylene glycol to obtain a porous polymer gel. This type of porous gel is used in the next step to prepare an ionic liquid gel transparent electrode.

[0043] (2) Preparation method of composite ionic liquid gel transparent electrode with enhanced mechanical properties

[0044] Soak the porous polymer gel formed in step (1) in an ethanol solution containing N-vinylpyridine tetrafluoroborate, benzophenone, and polyethylene glycol dimethacrylate (N-vinylpyridine The weight ratio ...

Embodiment 3

[0050] (1) Preparation method of transparent porous polymer network

[0051] Sodium alginate and porogen silica gel are dispersed in water at a weight ratio of 1000 / 10, and stirred to a uniform state. Coat the above dispersion evenly on polytetrafluoroethylene, then soak it in a 5% calcium chloride aqueous solution to react for 2 minutes to form a gel, and then treat it with hydrofluoric acid to obtain a porous polymer gel. This type of porous gel Used in the next step to prepare ionic liquid gel transparent electrode.

[0052] (2) Preparation method of composite ionic liquid gel transparent electrode with enhanced mechanical properties

[0053] Soak the porous polymer gel formed in step (1) in an aqueous solution containing tributylvinylammonium (trifluoromethanesulfonyl) imide salt, ammonium persulfate, and N,N-methylenebisacrylamide ( The weight ratio of tributylvinylammonium (trifluoromethanesulfonyl) imide salt / ammonium persulfate / N,N-methylenebisacrylamide / water is 1000 / 10 / 20...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com