Oil resistant silicone rubber

A silicone rubber and oil-resistant technology, applied in the field of oil-resistant silicone rubber, can solve the problems of high temperature resistance and high cost of rubber materials

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

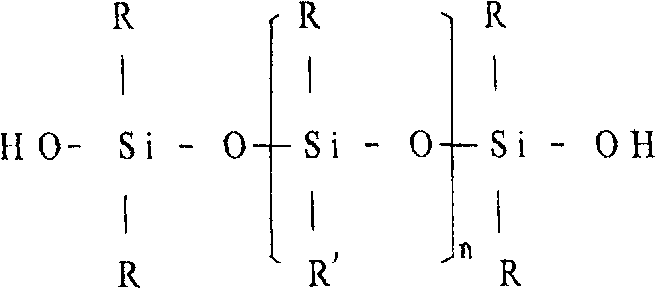

Method used

Image

Examples

preparation example Construction

[0087] A third aspect of the present invention provides a method for preparing the oil-resistant silicone rubber of the present invention, which includes the following steps:

[0088] providing the components described in the present invention;

[0089] The components are kneaded at 110-175° C., vacuumized and molded to obtain oil-resistant silicone rubber.

[0090] Preferably, the components are kneaded at 110-120°C.

[0091] In a specific embodiment of the present invention, the components are fed in a multi-feeding manner.

[0092] In a specific embodiment, 0.08% and 0.16% of raw rubber are put into the kneader, and the white carbon black is added in batches for about 3-4 times. When adding white carbon black, start to add hydroxyl silicone oil, and finally add hydrogen-containing silicone oil and dimethyl silicone oil when forming a group. Finally, the temperature in the kneader is about 110-120 ° C, and the rubber material is formed into a large group. Start vacuuming, ...

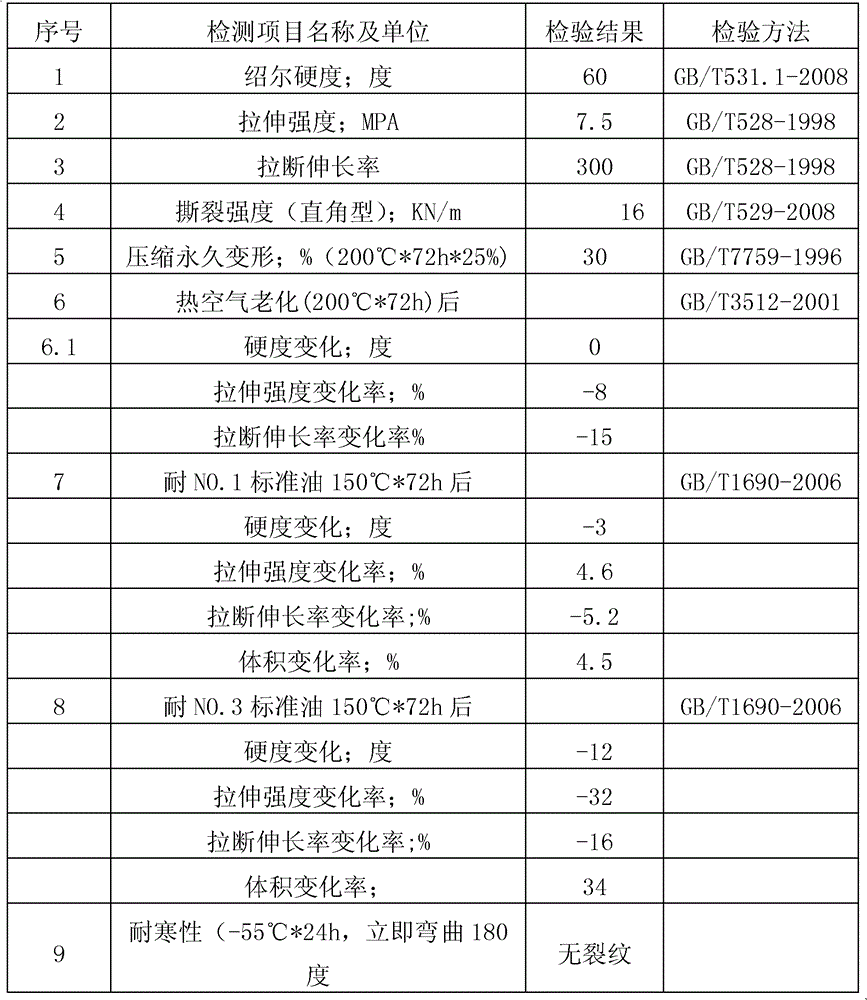

Embodiment 1

[0099] Summary of the invention: The formula is as follows by improving the ratio of silica gel and raw materials:

[0100] Use methyl vinyl raw rubber 0.08% 71 parts, 0.16% 29 parts, molecular weight between 580,000 and 620,000, 2.2 parts of hydroxyl silicone oil, 1.4 parts of hydrogen-containing silicone oil, 1.1 parts of methyl silicone oil, 0.42 parts of zinc stearate, Degu Sai 928 white carbon black 42 parts, 3000 mesh clay 29 parts, polytetrafluoroethylene 9 parts, silane coupling agent A-1721.2 parts.

[0101] The glue process is as follows:

[0102] Put 0.08% and 0.16% raw rubber into the kneader, add the silica in batches for about 3-4 times, add the next silica after each formation, and start adding the silica for the second time Hydroxyl silicone oil, add hydrogen-containing silicone oil and methyl silicone oil when forming a group at the end, the temperature in the kneader is about 110-120 ℃, the rubber material forms a large group, start vacuuming, the vacuum deg...

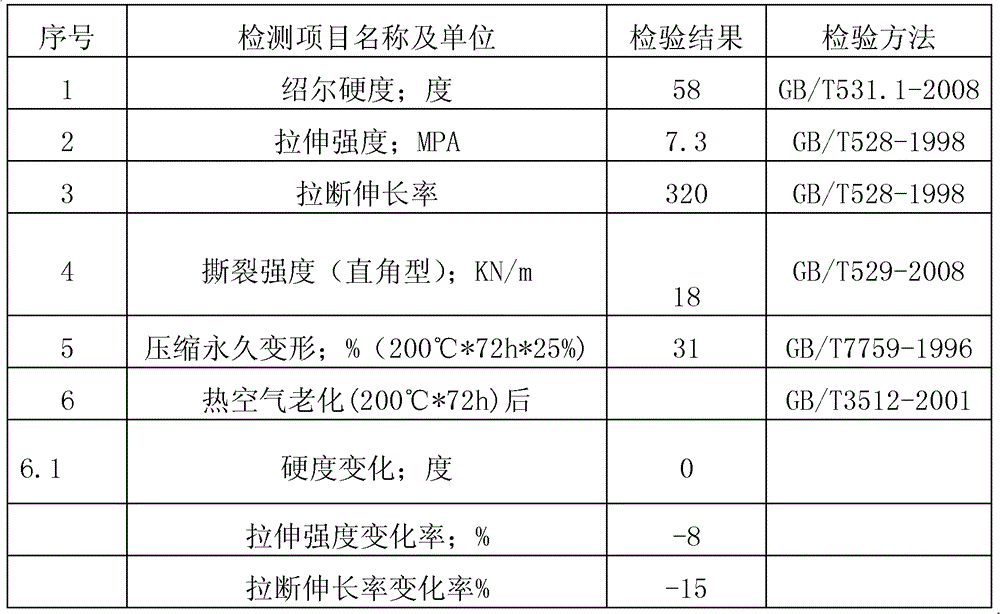

Embodiment 2

[0107] Summary of the invention: The formula is as follows by improving the ratio of silica gel and raw materials:

[0108] Use methyl vinyl raw rubber 0.07% 71 parts, 0.15% 29 parts, molecular weight 580,000-620,000, 2.2 parts of hydroxyl silicone oil, 1.4 parts of hydrogen-containing silicone oil, 1.1 parts of methyl silicone oil, 42 parts of precipitated white carbon black, 3000 29 parts of clay, 9 parts of polytetrafluoroethylene, 1721.2 parts of silane coupling agent A-172.

[0109] The glue process is as follows:

[0110] Put 0.08% and 0.16% raw rubber into the kneader, add the silica in batches for about 3-4 times, add the next silica after each formation, and start adding the silica for the second time Hydroxyl silicone oil, add hydrogen-containing silicone oil and methyl silicone oil when forming a group at the end, the temperature in the kneader is about 110-120 ℃, the rubber material forms a large group, start vacuuming, the vacuum degree is -0.075±0.002, and the v...

PUM

| Property | Measurement | Unit |

|---|---|---|

| degree of polymerization | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com