A kind of preparation method of phytosterol ester

A technology of phytosterol esters and phytosterols, which is applied in the field of preparation of phytosterol esters, can solve the problems of high temperature resistance and many side reactions of cation exchange resins, and achieve the effects of overcoming severe corrosion of equipment, overcoming high temperature resistance, and high conversion rate

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation Embodiment 1

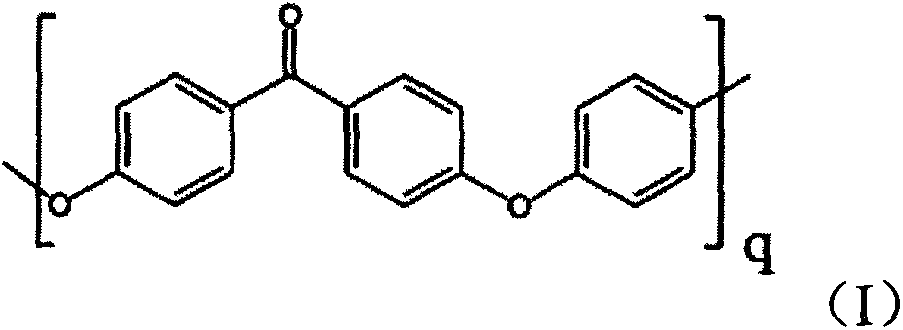

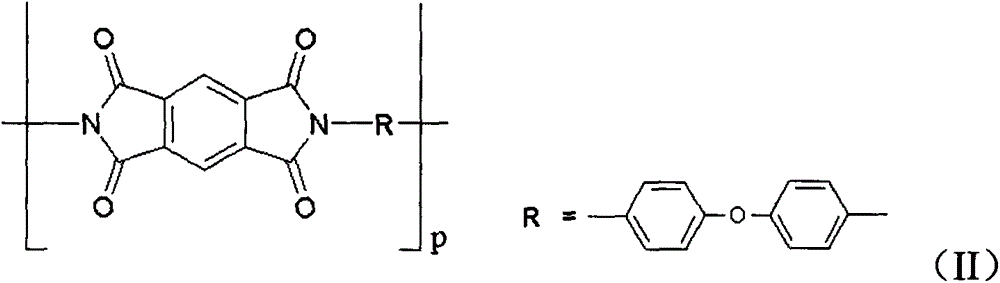

[0045] Preparation Example 1: Preparation of High Temperature Resistant Polymer Catalytic Membrane

[0046] First, carbon fiber non-woven fabrics (purchased from Beijing Jucheng Zhonggu Technology Co., Ltd.) were soaked in 5 g / L NaOH ethanol solution at 40°C for 2 hours, then the samples were taken out and washed with ethanol and placed in a refrigerator at a temperature of 80°C. Dry in an electric heating constant temperature air blast drying oven, and cut the pretreated nonwoven fabric into small pieces with an area of 10cm×10cm for later use.

[0047] Dissolve 150 grams of sulfonated polyetheretherketone powder (purchased from Haipu Poly) with a sulfonation degree of 30% in 850 grams of N,N-dimethylpyrrolidone solvent to form a cast film with a mass concentration of 15%. liquid; then immerse the pretreated non-woven fabric in the casting solution, so that the non-woven fabric and the casting solution are fully infiltrated, take it out after 30 minutes and put it into the ...

preparation Embodiment 2

[0049] Preparation Example 2: Preparation of High Temperature Resistant Polymer Catalytic Membrane

[0050] Prepare the high-temperature-resistant polymer catalytic membrane with the same method as Preparation Example 1, the difference is that the non-woven fabric used is a basalt fiber non-woven fabric (purchased from Yancheng Shibang Cloth Industry Co., Ltd.), and the non-woven fabric was previously Soak with ethanol solution at 40°C for 3 hours.

[0051] The ion exchange capacity of the obtained membrane was measured by the method of acid-base titration to be 1.5 mmol / g membrane.

preparation Embodiment 3

[0052] Preparation Example 3: Preparation of High Temperature Resistant Polymer Catalytic Membrane

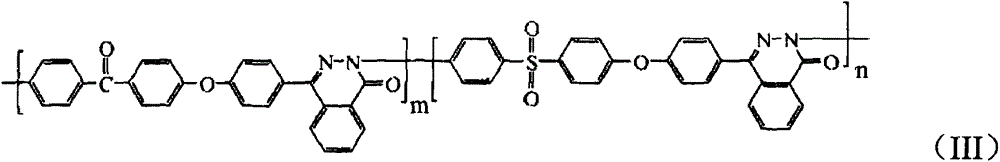

[0053] A high temperature resistant polymer catalytic membrane was prepared in the same manner as in Preparation Example 1, except that no support layer was used. The high temperature resistant polymer catalyst material used is sulfonated polyarylether sulfone ketone (provided by Dalian University of Technology), and the sulfonation degree is 90%. Pour the prepared casting solution directly on the flat glass, and cast and scrape the film. After about 1 minute, put the glass plate with the casting solution in the ethanol coagulation bath for 30 minutes, so as to solidify and form, and obtain a porous composite membrane.

[0054] The ion exchange capacity of the resulting membrane was measured by acid-base titration to be 5 mmol / g membrane.

[0055] Synthesis Example 1: Synthesis of Phytosterol Esters

[0056] Cut the catalytic membrane of sulfonated polyetheretherketone (purch...

PUM

| Property | Measurement | Unit |

|---|---|---|

| degree of substitution | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com