Flexible fire-proof cable and its producing process and producing device

A fireproof cable, flexible technology, applied in the direction of insulated cables, power cables, cables, etc., can solve the problems of complex fireproof power cable manufacturing process, complex fireproof cable equipment, power cables not resistant to high temperature, etc., and achieves a high degree of automation and high speed. , Excellent high temperature resistance effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

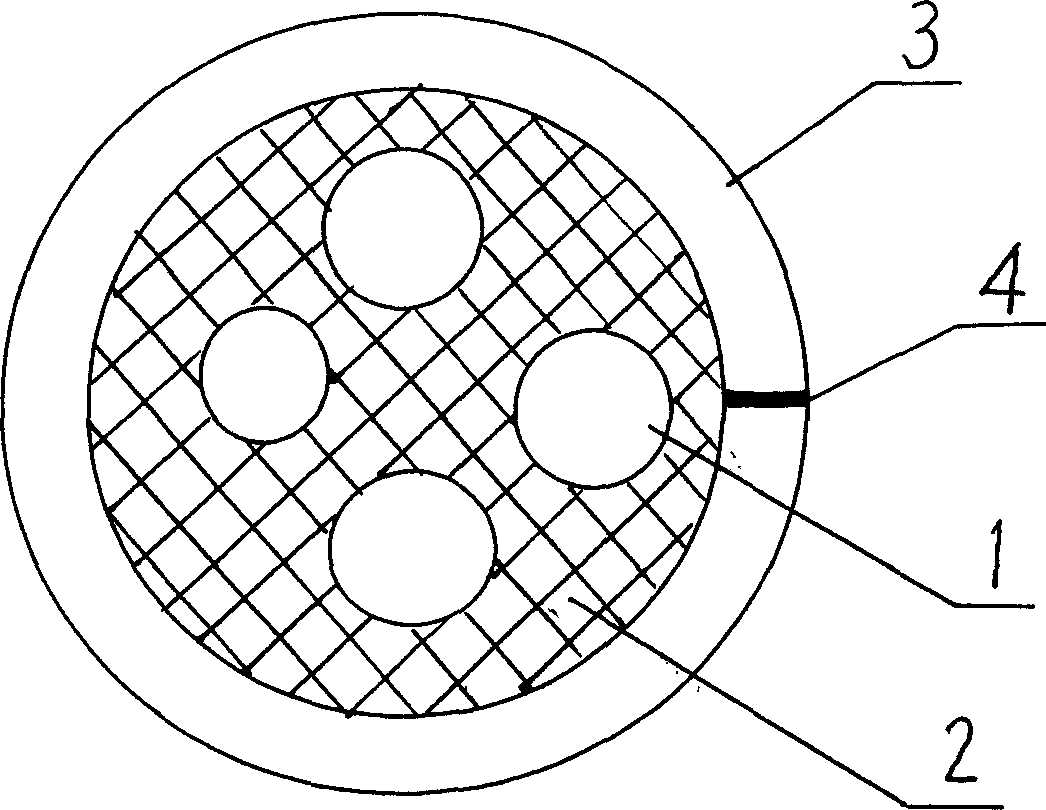

[0023] Examples of flexible fireproof cables refer to figure 1 , a group of metal cores 1 are evenly distributed, and the surroundings are isolated from each other by mica tape insulating layer 2 and wrapped, and outside the mica tape insulating layer is wrapped by metal tape 3, and there is a weld 4 in the longitudinal direction of the cable, and the cable is welded into smooth The metal sheath forms a flexible fireproof cable.

[0024] The mica tape insulating layer 2 can be replaced by a glass fiber tape, asbestos tape or a mixed inorganic material insulating tape made of metal oxide. The insulated core wire is made by wrapping or longitudinal wrapping. The number of a group of metal cores can be 1-42. The multi-core metal wire core is formed by twisting multiple strands of metal wires, and the multiple strands of metal wires can be 1 to 54 strands. The metal sheath can be rolled with "grain" to form a metal sheath with "grain". The metal core is made of copper, copper...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com