Pin-type load-bearing/protection integrated high-strength polyethylene composite armored bulkhead structure

A high-strength polyethylene and pinning technology, which is applied to hull bulkheads, hulls, and hull panels, can solve problems such as failure of connection interfaces, reduction of overall protection performance of bulkhead structures, and low shear strength of weak connection interfaces. Improve the interlayer strength, improve the bearing capacity and anti-penetration performance, and the effect of high specific stiffness

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

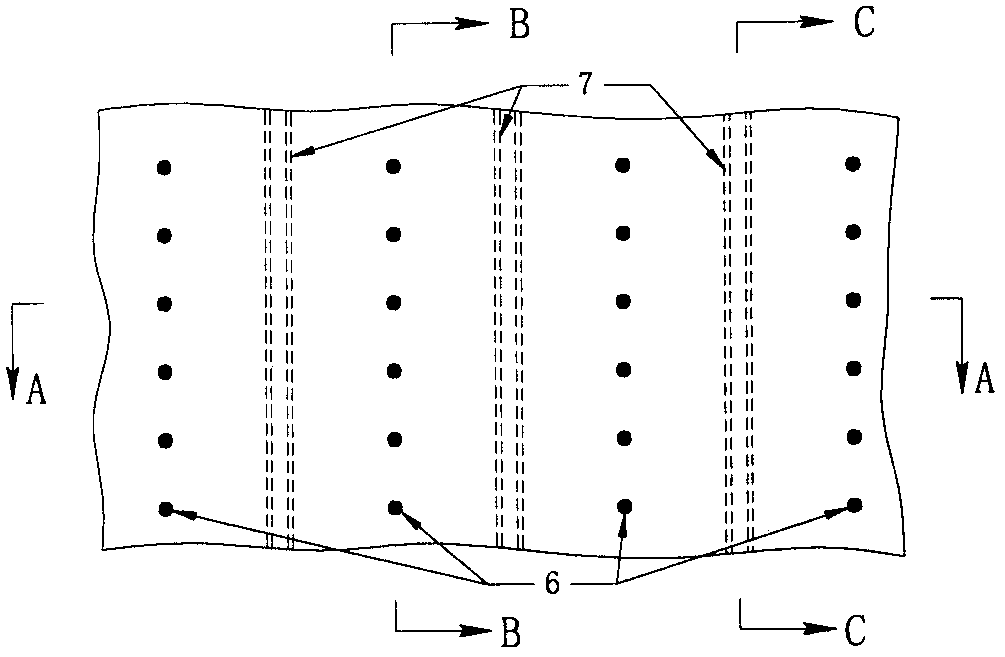

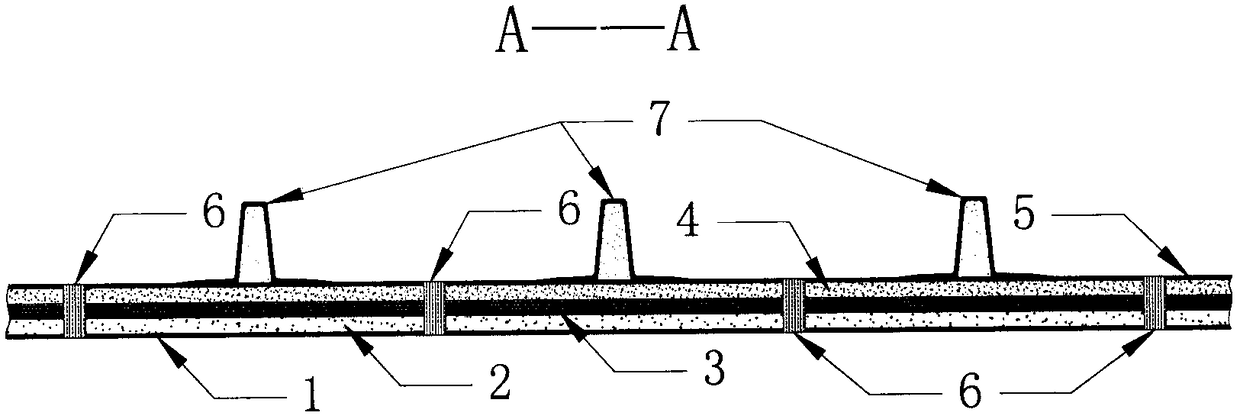

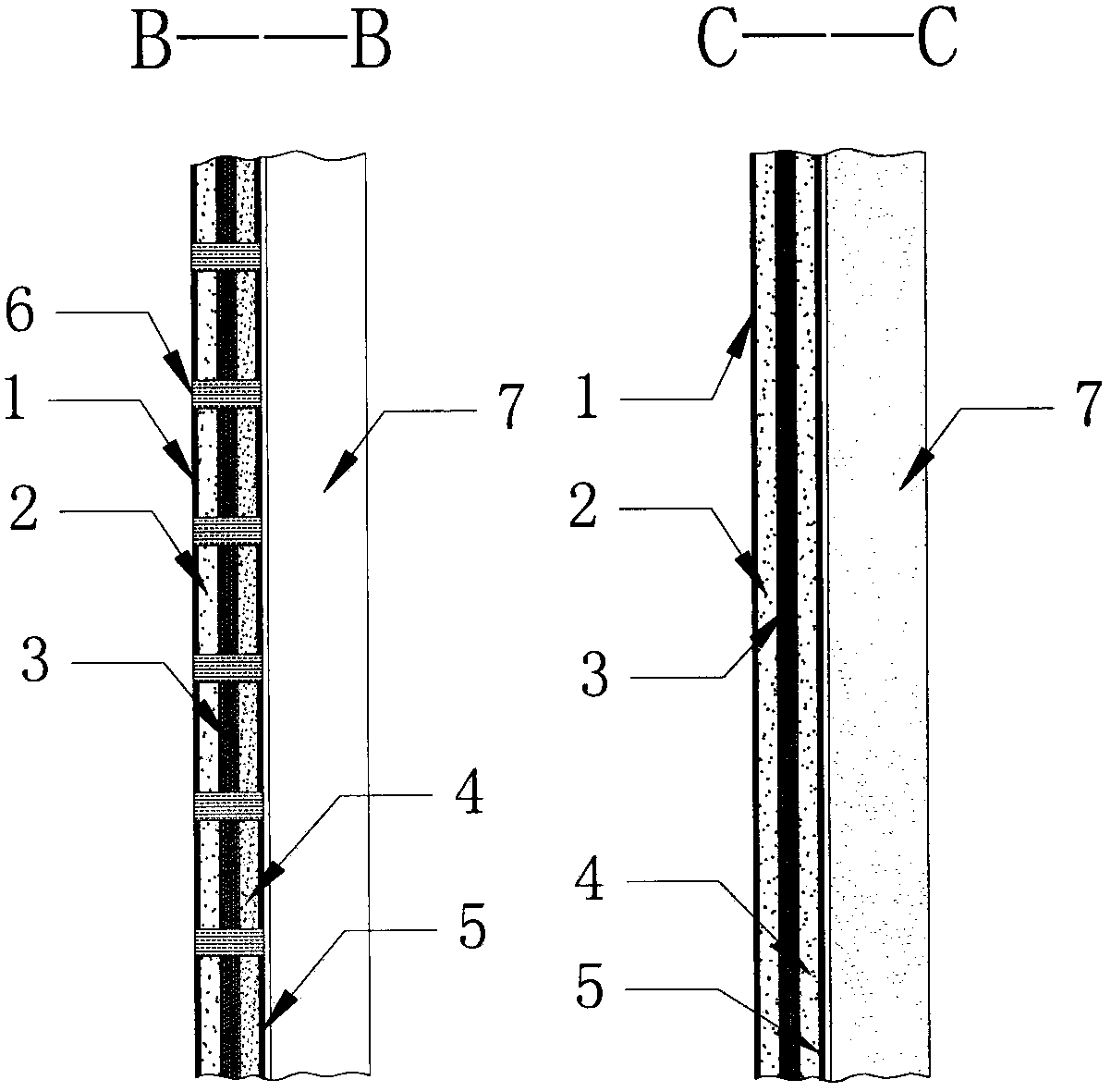

[0017] see figure 2 , the pinning type bearing / protection integrated high-strength polyethylene composite armored bulkhead structure of the present invention is composed of sandwich panels and hat-shaped reinforcing ribs. The sandwich panel consists of a front panel (1), a buffer heat insulation layer (2), a high-strength polyethylene fiber ballistic layer (3), an energy-absorbing heat insulation layer (4), a rear panel (5) and restraining fiber nails ( 6) Composition. The front panel (1) and the rear panel (5) can adopt fiber reinforced composite materials, and the fiber reinforced composite materials can adopt high-strength glass fibers, high-strength carbon fibers, basalt fibers and hybrid fiber-reinforced composite materials thereof; The heat insulation layer (2) and the energy-absorbing heat insulation layer (4) can adopt heat insulation materials with light bulk density and small thermal conductivity, and the heat insulation materials can adopt airgel felt, PVC foam, p...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com