Fiber winding fiber reinforced plastic pipeline structure and sand inclusion layer manufacturing method and device

A technology of glass fiber reinforced plastic and sand interlayer, applied in the field of filament winding, can solve the problems of low strength, poor flexibility, unsatisfactory tensile strength and stiffness, etc., to improve flexibility, enhance bonding force and interlayer strength, and enhance adsorption. force effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0016] In order to make the above objects, features and advantages of the present invention more comprehensible, the present invention will be further described in detail below in conjunction with the accompanying drawings and specific embodiments.

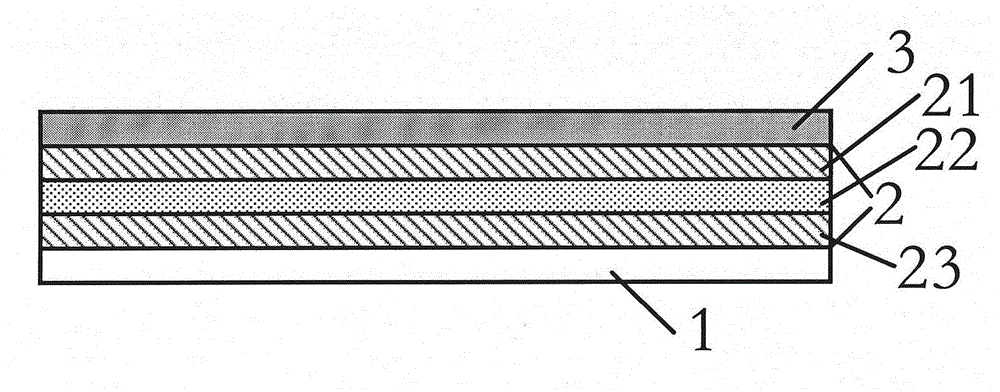

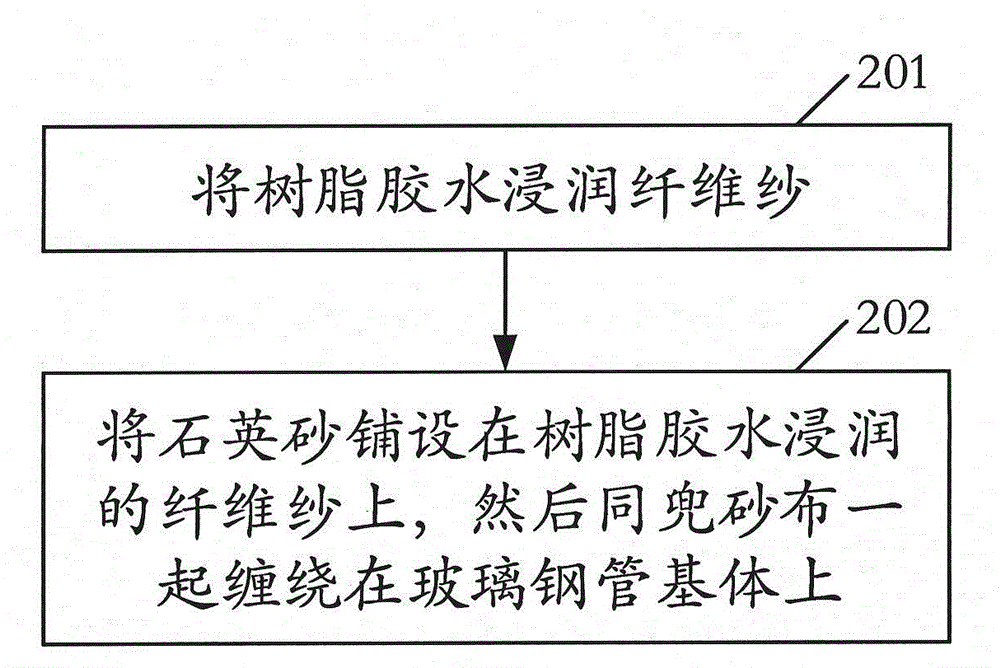

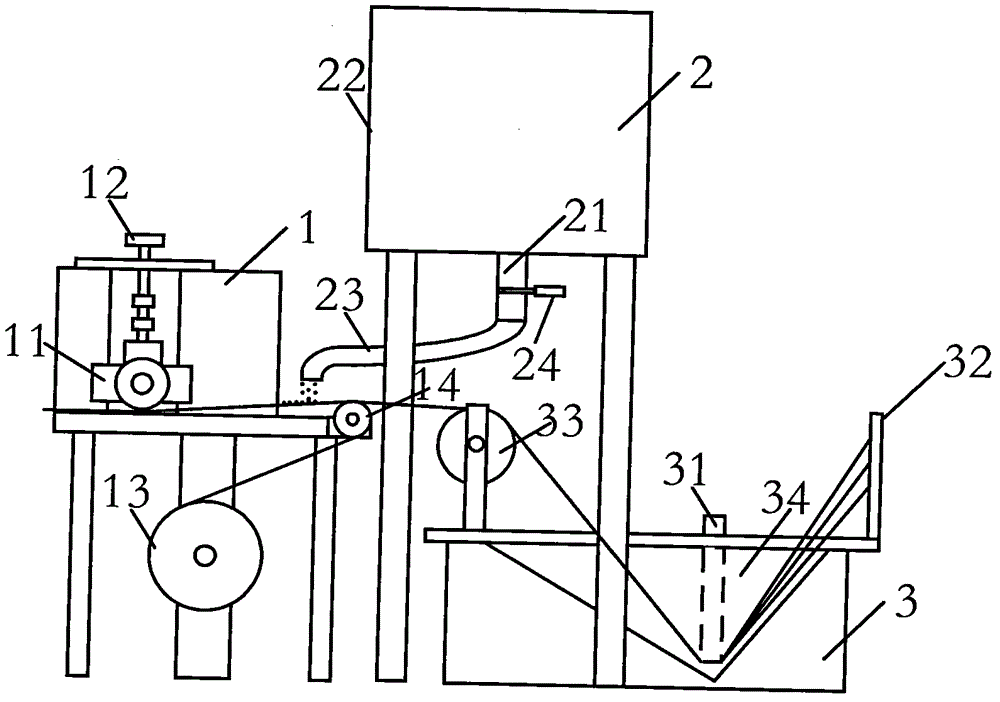

[0017] The embodiment of the present invention provides a schematic view of the structure of a fiber-wound FRP pipe, such as figure 1 As shown, it includes: an inner lining layer 1, a structural layer 2 and an outer protective layer 3, and the structural layer 2 includes an outer winding layer 21, a sand inclusion layer 22 and an inner winding layer 23, and the outer winding layer 21 and the inner winding layer The winding layer 23 is compounded by glass fibers impregnated with resin glue, and the sand inclusion layer 22 is composed of sand cloth and quartz sand impregnated with resin glue wrapped around fiber yarns.

[0018] Wherein, the sand interlayer may also be composed of sand cloth and fiber yarn wound with resin glue soake...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com