Amorphous polyaryletherketone/sulfone powder for laser sintering 3D printing and preparation method of amorphous polyaryletherketone/sulfone powder

A technology of laser sintering and polyaryletherketone, which is applied in the field of additive manufacturing, can solve the problems of low powder fluidity, wide particle size distribution of powder particles, and low yield.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

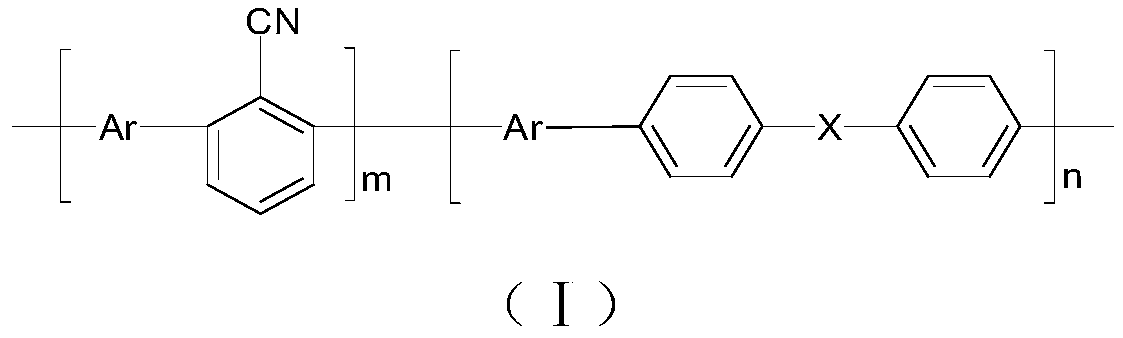

[0028] The present invention at first provides a kind of preparation method of amorphous polyaryletherketone / sulfone powder for laser sintering, the method comprises:

[0029] Step 1: Dissolve the coarse powder of amorphous polyarylether nitrile ketone / sulfone resin in a solvent, then blend it with water, stabilizer, and emulsifier in a reaction vessel, and stir at a high speed at 40-50°C to form an emulsion; The solvent is preferably N,N-dimethylformamide, N,N-dimethylacetamide, dimethyl sulfoxide, N-methylpyrrolidone, methylene chloride or tetrahydrofuran; the stabilizer is preferably PVA, The emulsifier is preferably glycerol, the mass ratio of the amorphous polyarylether nitrile ketone / sulfone resin to the solvent is preferably 1:(1-5), and the mass ratio of the solvent, water, stabilizer and emulsifier is preferably It is 1:(5~15):0.2:0.2. The stirring rate is greater than 400rpm, and the stirring time is preferably 1-2h.

[0030] Step 2: Gradiently raise the temperatur...

Embodiment 1

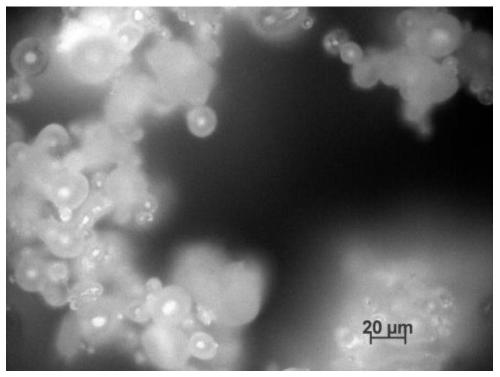

[0042] Dissolve 5 g of coarse powder of amorphous polyaryletherketone resin (structure shown in II) in dichloromethane (10 g), and then mix with water (90 g), stabilizer (PVA, 2 g), emulsifier (glycerin, 2 g) Blended in a reaction vessel, stirred at 40°C for 2 hours at high speed to form an emulsion; gradually increased the temperature, each time by 10°C and kept warm for 0.5h, and finally raised to 90°C, distilled off the solvent dichloromethane; cooled to room temperature, filtered, and respectively used Wash the filter cake twice with ethanol and water, and dry it in vacuum at 180°C for 4 hours to obtain a dense microsphered amorphous polyaryletherketone powder with a bulk density of 0.4g / cm 3 , with a uniform particle size of about 20 μm.

[0043]

[0044] Wherein, m=0, n=1.

[0045] figure 1 It is a polarized light microscope image of the dense microsphered amorphous polyaryletherketone prepared in Example 1 of the present invention.

Embodiment 2

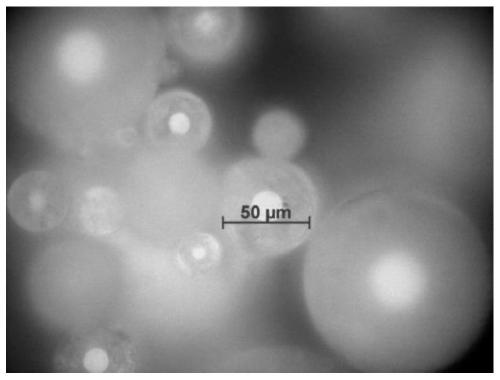

[0047] Dissolve 5 g of coarse powder of amorphous polyaryletherketone resin (structure shown in III) in dichloromethane (10 g), then mix with water (100 g), stabilizer (PVA, 2 g), emulsifier (glycerin, 2 g) Blended in a reaction vessel, stirred at 40°C for 2 hours at high speed to form an emulsion; gradually increased the temperature, each time by 10°C and kept warm for 0.5h, and finally raised to 90°C, distilled off the solvent dichloromethane; cooled to room temperature, filtered, and respectively used Wash the filter cake twice with ethanol and water, and dry it in vacuum at 180°C for 4 hours to obtain a dense microsphered amorphous polyarylether nitrile ketone powder with a bulk density of 0.45-0.5g / cm 3 , with a uniform particle size of about 50 μm.

[0048]

[0049]

[0050] Wherein, m=0.7, n=0.3.

[0051] figure 2 It is a polarized light microscope picture of the dense microsphered amorphous polyarylether nitrile ketone prepared in Example 2 of the present inve...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com