Sulfur-free and pearlite-free firecracker reagent and preparation method thereof

A technology of perlite and firecrackers, which is applied in the direction of explosives, etc., can solve the problems of storage stability defects and high production costs, and achieve the effects of being beneficial to environmental protection, reducing the decomposition temperature, and increasing the rate of oxygen release

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

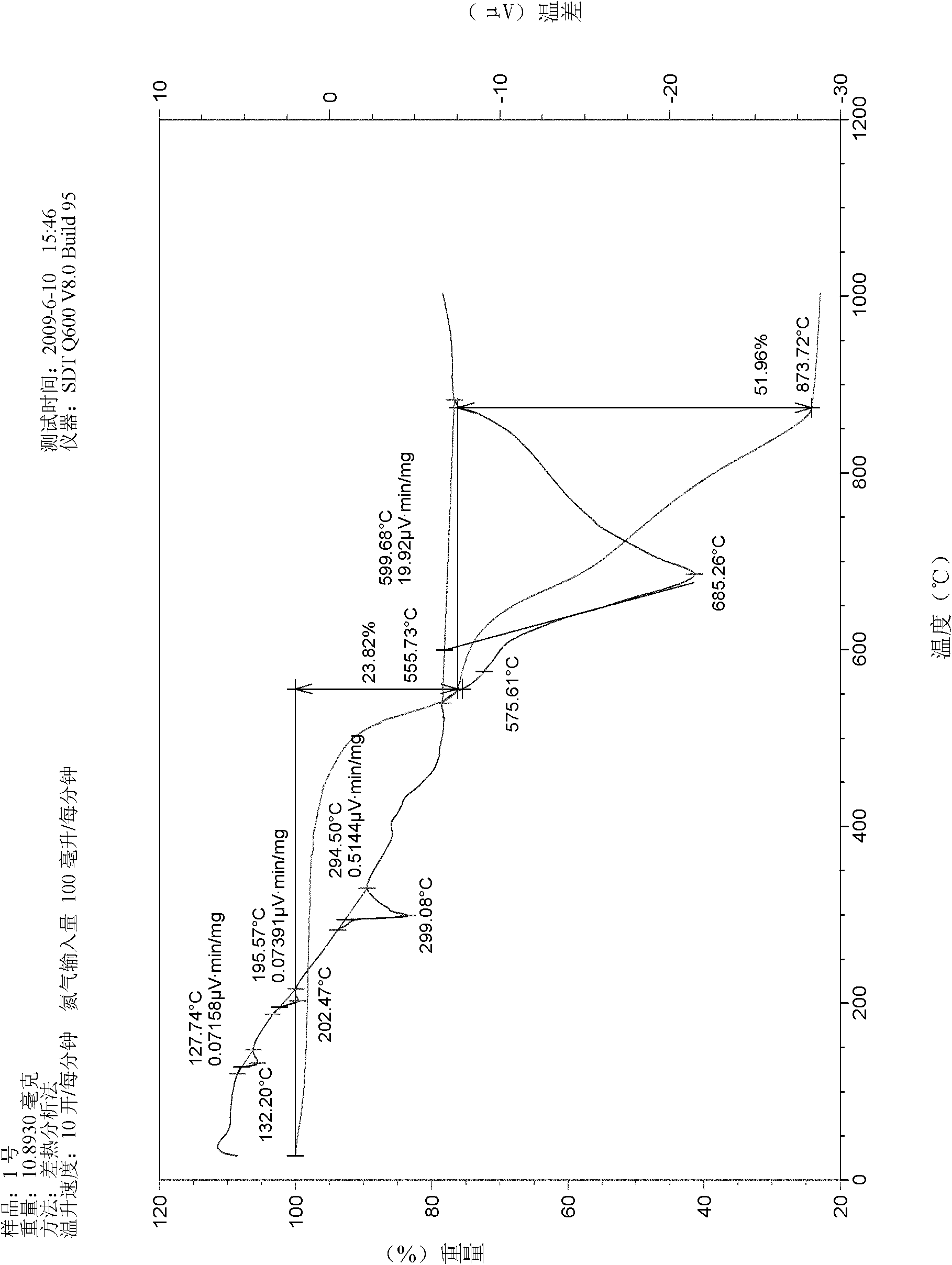

Embodiment 1

[0034] Make the potion according to the following ratio

[0035] Component A: Potassium perchlorate 40%, potassium nitrate 30%, barium nitrate 30% to form a mixture, tartaric acid accounting for 3% of the mixture;

[0036] Component B: aluminum silver powder 65%, charcoal powder 10%, organic foaming powder 25%.

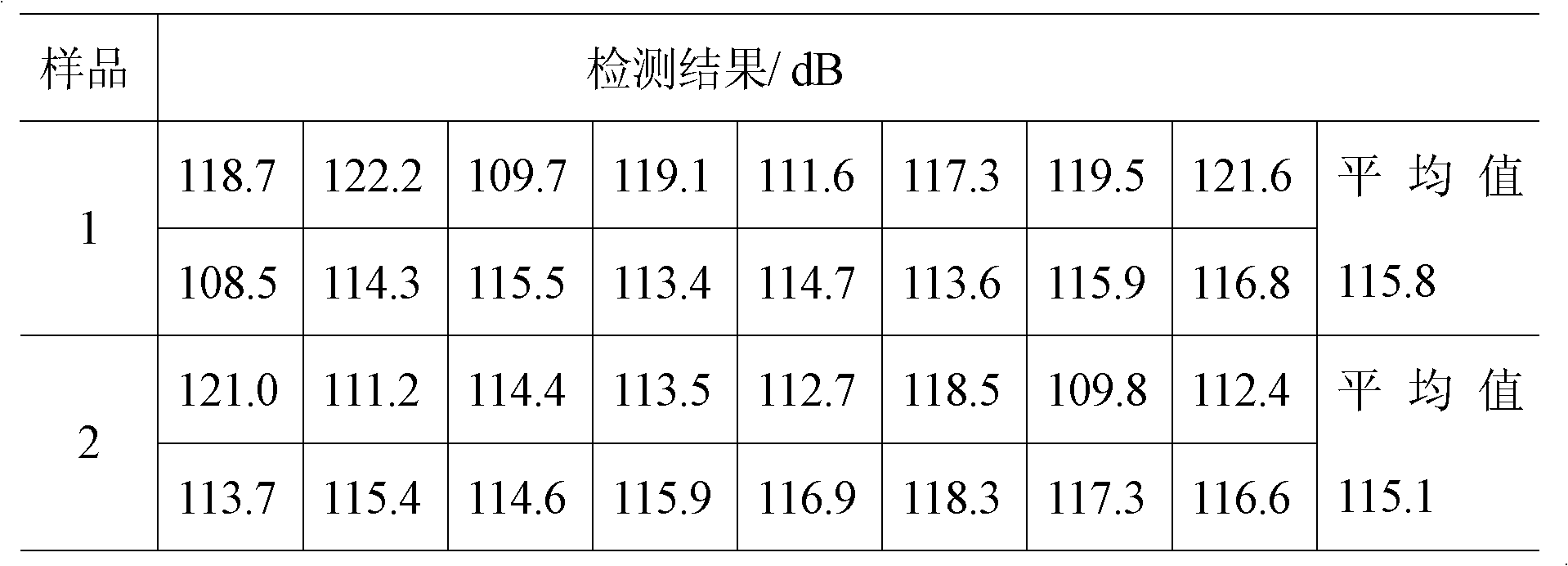

[0037] Produce firecrackers by the firecracker medicine that 60% A component and 40% B component are formed again. The test results are as follows:

[0038] Sound level: 108.5dB ≤ sound level value should be ≤ 122.2dB;

[0039] The time for the gas product pressure to rise from 0.69MP to 2.07MP is 1.74ms,

[0040] The pH value of the pyrotechnic powder is in the range of 5 to 9;

[0041] Moisture content of pyrotechnic powder ≤ 1.5%;

[0042] The moisture absorption rate of pyrotechnic powder is ≤2.0%;

[0043] The thermal stability of the pyrotechnic powder is that there is no decomposition phenomenon at 75°C±2°C for 48 hours;

[0044] The friction sensitivity...

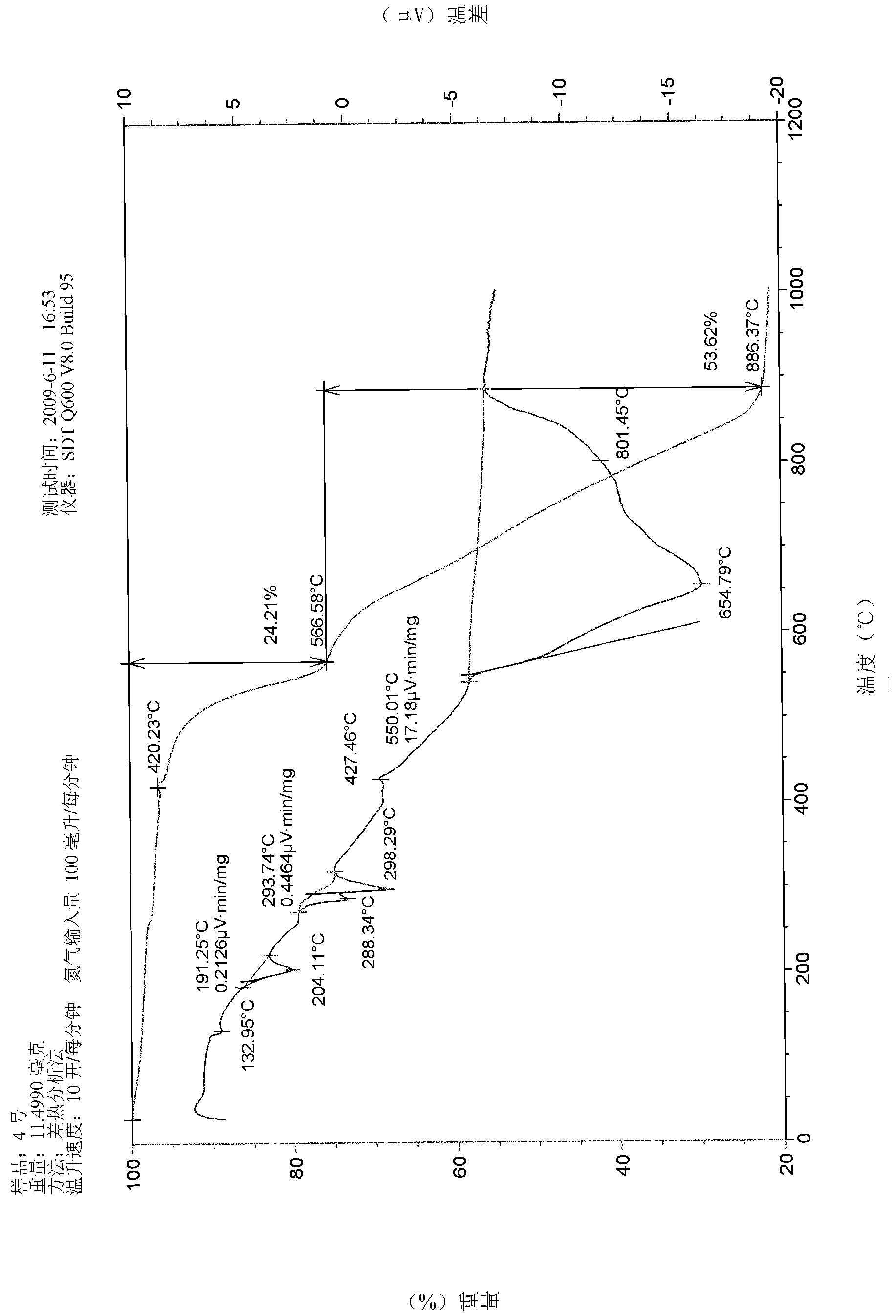

Embodiment 2

[0048] Component A: Potassium perchlorate 20%, potassium nitrate 30%, barium nitrate 50% to form a mixture, tartaric acid accounting for 1% of the mixture;

[0049] Component B: Aluminum silver powder 75%, charcoal powder 20%, organic foaming powder 15%.

[0050] Produce firecrackers by the firecracker medicine that 50% A component and 50% B component are formed again. The test results are as follows:

[0051] The explosion rate is over 95%;

[0052] The firing rate reaches over 98%;

[0053] Sound level: 105.5dB ≤ sound level value should be ≤ 120.2dB;

[0054] The time for the gas product pressure to rise from 0.69MP to 2.07MP is 1.75ms;

[0055] The pH value of the pyrotechnic powder is in the range of 5 to 9;

[0056] Moisture content of pyrotechnic powder ≤1.02%;

[0057] The moisture absorption rate of pyrotechnic powder is ≤2.0%;

[0058] The thermal stability of the pyrotechnic powder is that there is no decomposition phenomenon at 75°C±2°C for 48 hours;

[005...

Embodiment 3

[0062] Component A: a mixture of potassium perchlorate 50%, potassium nitrate 10%, barium nitrate 40%, tartaric acid accounting for 5% of the mixture;

[0063] Component B: Aluminum silver powder 60%, charcoal powder 25%, organic foaming powder 15%.

[0064] Component A is 50%, and component B is 50%. The test results are as follows:

[0065] The explosion rate is over 95%;

[0066] The firing rate reaches over 98%;

[0067] Sound level: 107.5dB ≤ sound level value should be ≤ 125.2dB;

[0068] The time for the gas product pressure to rise from 0.69MP to 2.07MP is 1.8ms;

[0069] The pH value of the pyrotechnic powder is in the range of 5 to 9;

[0070] Moisture content of pyrotechnic powder ≤1.10%;

[0071] The moisture absorption rate of pyrotechnic powder is ≤2.0%;

[0072] The thermal stability of the pyrotechnic powder is that there is no decomposition phenomenon at 75°C±2°C for 48 hours;

[0073] The friction sensitivity of pyrotechnic powder is ≤35%;

[0074] Th...

PUM

| Property | Measurement | Unit |

|---|---|---|

| water absorption | aaaaa | aaaaa |

| relative humidity | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com