High-elasticity color antiskid wearing layer

A high-elasticity and color technology, applied to the coagulation pavement, roads, roads and other directions paved on site, can solve the problems of cracking, limited use field, brittleness of anti-slip and wear layer materials, etc., to achieve simple formula, convenient production, Excellent low temperature performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0033] Example 1: Prepare 3000 g of the highly elastic colored anti-skid wear layer of the present invention, and test the road performance of the material.

[0034]

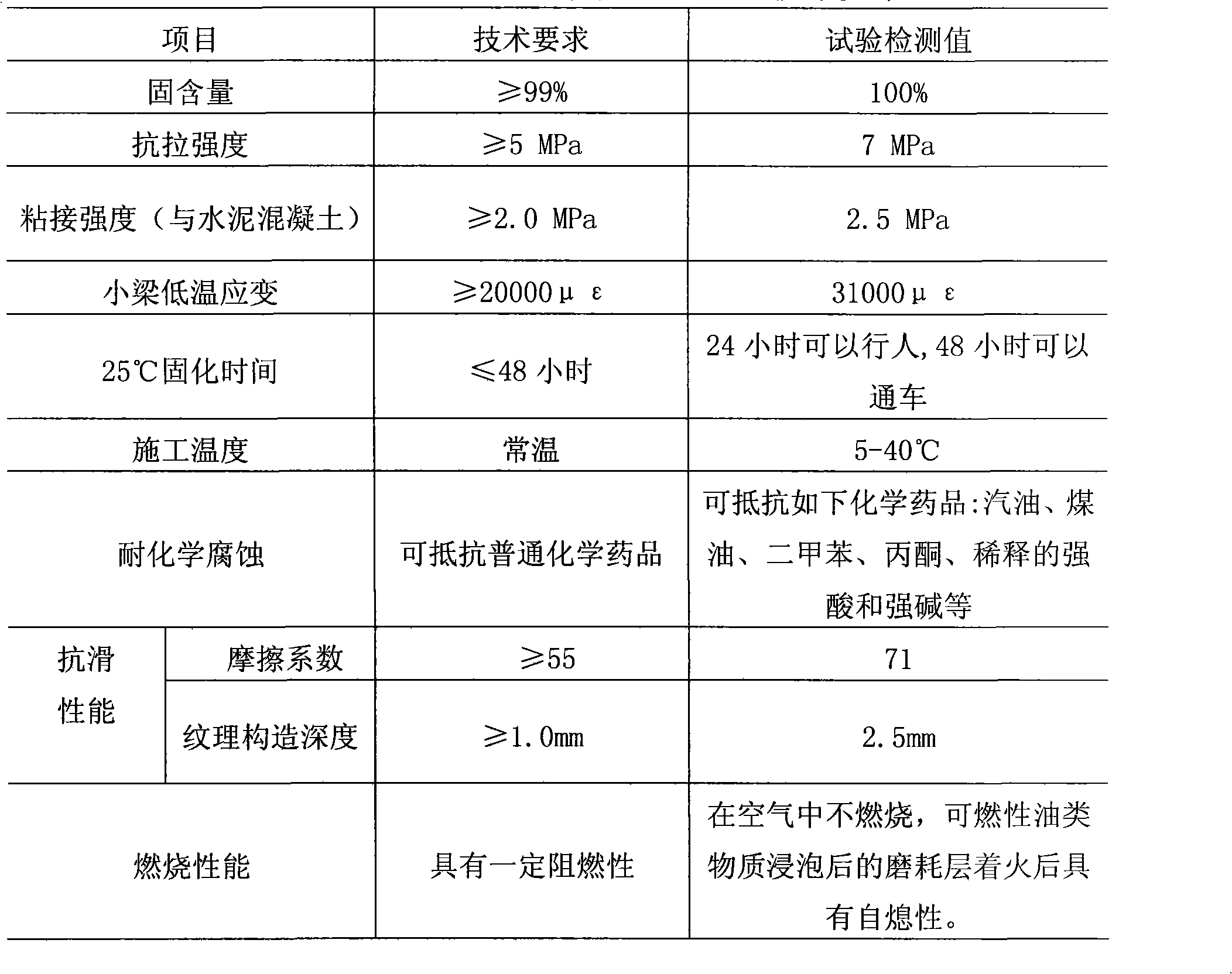

[0035] The base asphalt is melted at 140°C and added to the reaction kettle, then the compatibilizer, rheology agent, anti-ultraviolet aging agent and curing agent are added in sequence, the temperature is controlled at 90±5°C, and stirred for 2 to 3 hours to form the B component, and the A Components and B components are mixed evenly in proportion at room temperature, and then fine stones are added and stirred evenly. According to the test requirements, after forming various test specimens, sprinkle colored wear-resistant glass beads. The test results are as follows:

[0036]

[0037] It can be seen from the test results that the various performances of the colored anti-skid wear layer material used in Example 1 can meet the technical requirements, and the performance is good.

Embodiment 2

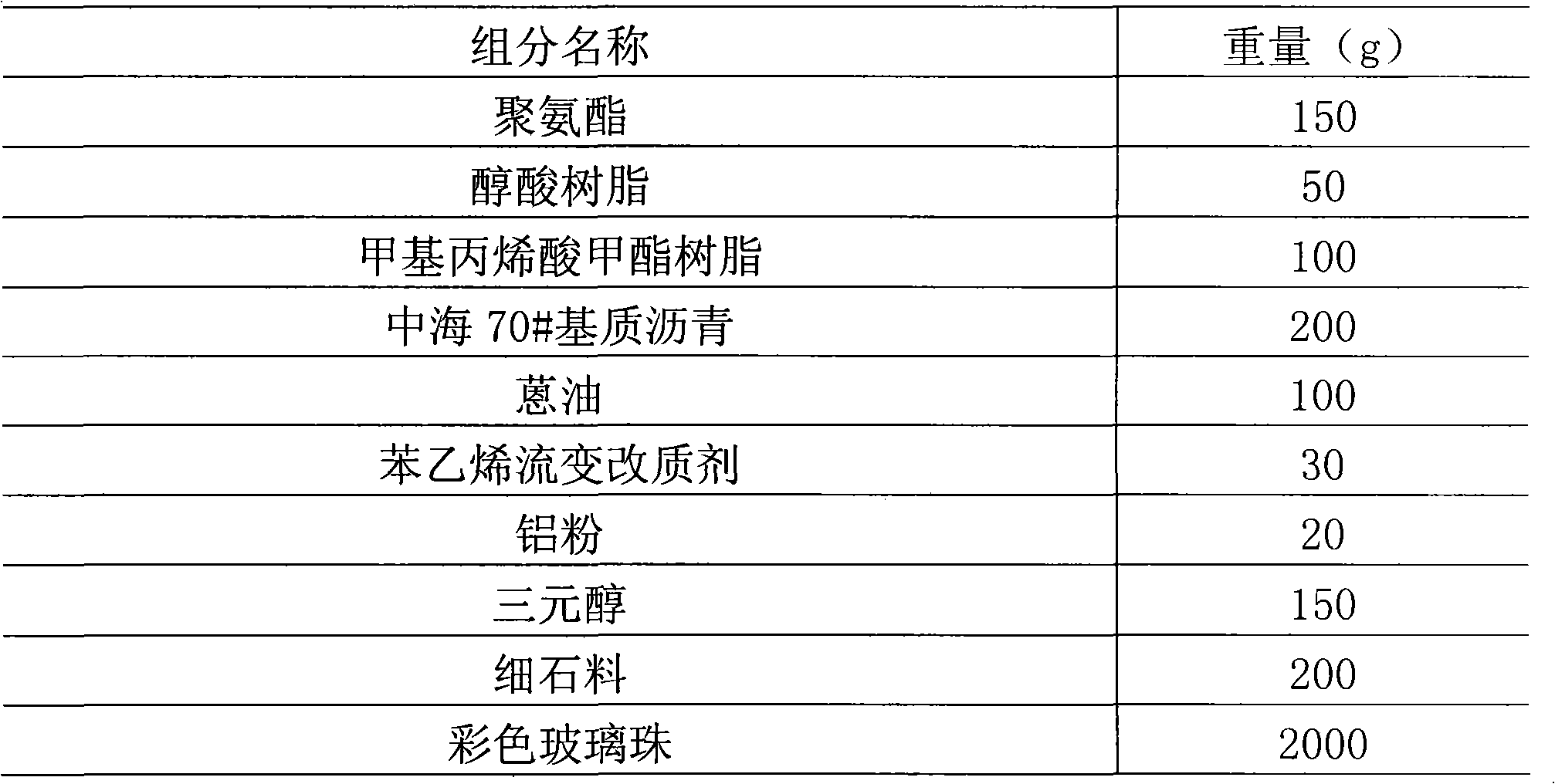

[0038] Example 2: Prepare 3000 g of the highly elastic colored anti-skid and wear layer of the present invention, and test the road performance of the material.

[0039]

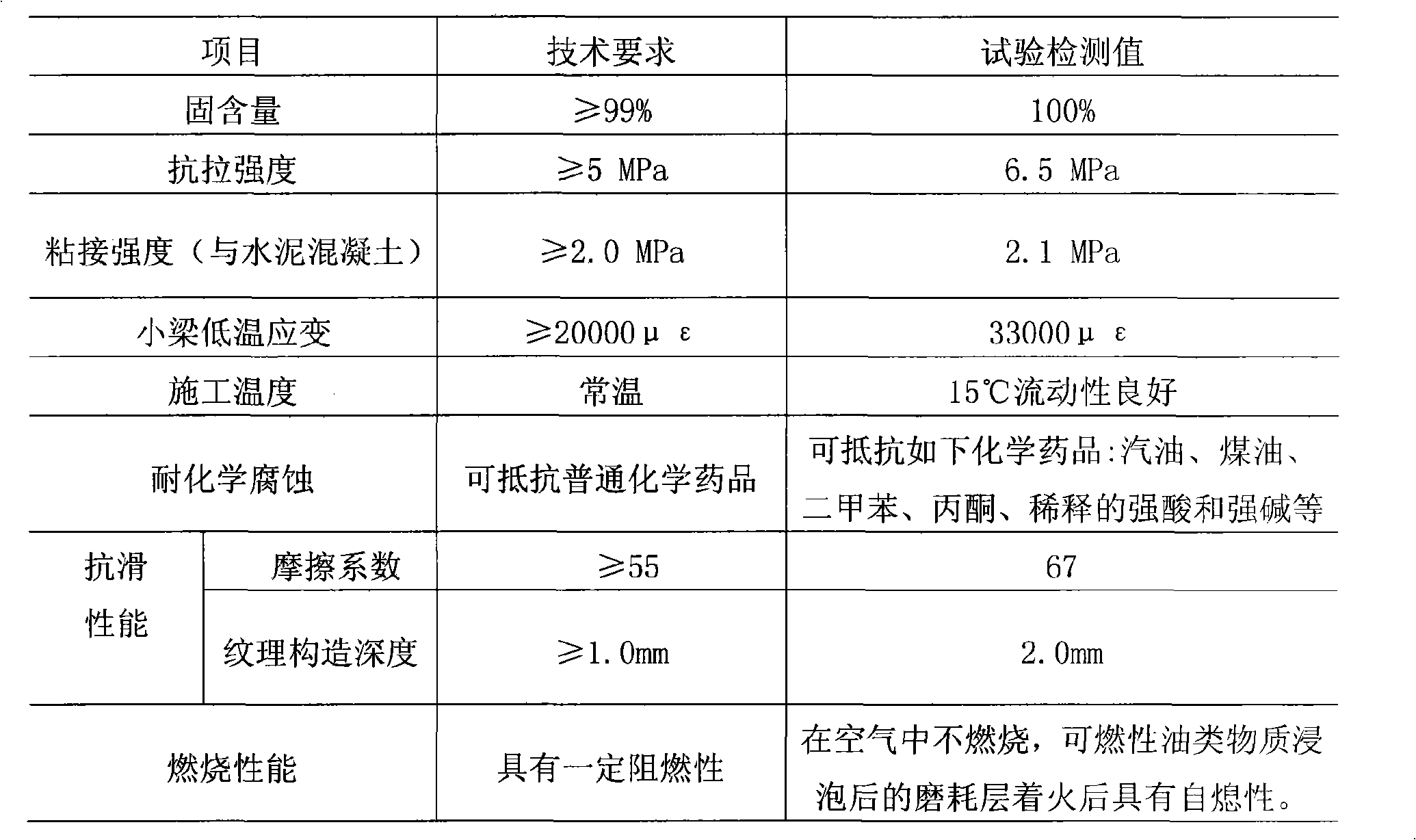

[0040] The base asphalt is melted at 140°C and added to the reaction kettle, then the compatibilizer, rheology agent, anti-ultraviolet aging agent and curing agent are added in sequence, the temperature is controlled at 90±5°C, and stirred for 2 to 3 hours to form the B component, and the A Component and B component are mixed evenly in proportion at room temperature, then add fine stones and stir evenly. According to the test requirements, after forming various test specimens, sprinkle colored wear-resistant granite stone materials, the test results are as follows:

[0041]

[0042] It can be seen from the test results that the various properties of the colored anti-skid wearing layer material used in Example 2 can meet the technical requirements, and the performance is good.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com