Biomass semi-gasification heating system

A heating system, semi-gasification technology, applied in the heating system, combustion air/fuel supply, chemical industry, etc., can solve the problems of generating a lot of smoke or harmful gas, the tar problem cannot be solved, and the combustion process is unstable , to reduce the risk of being scalded, use and maintain low costs, and reduce manual labor

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

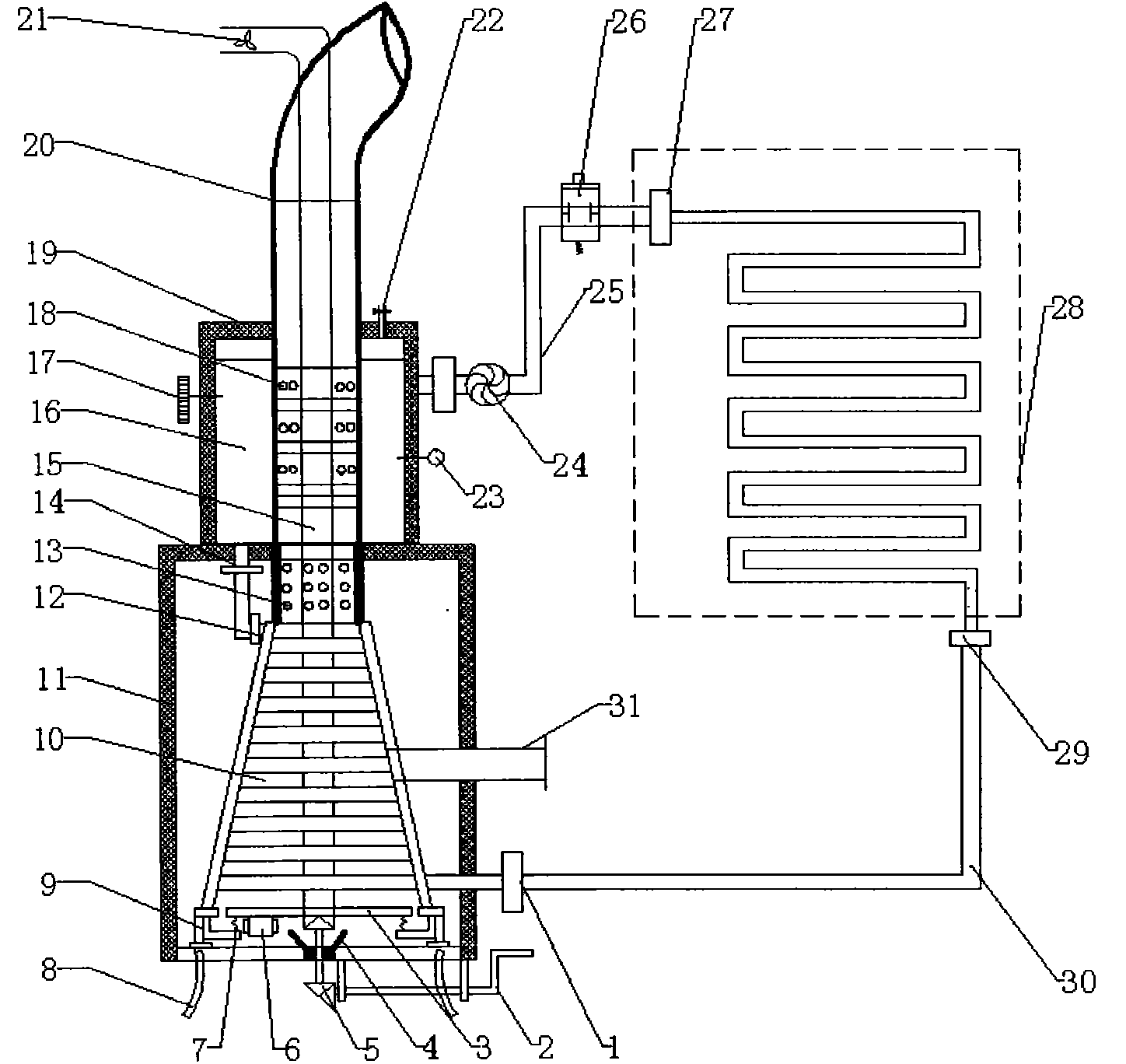

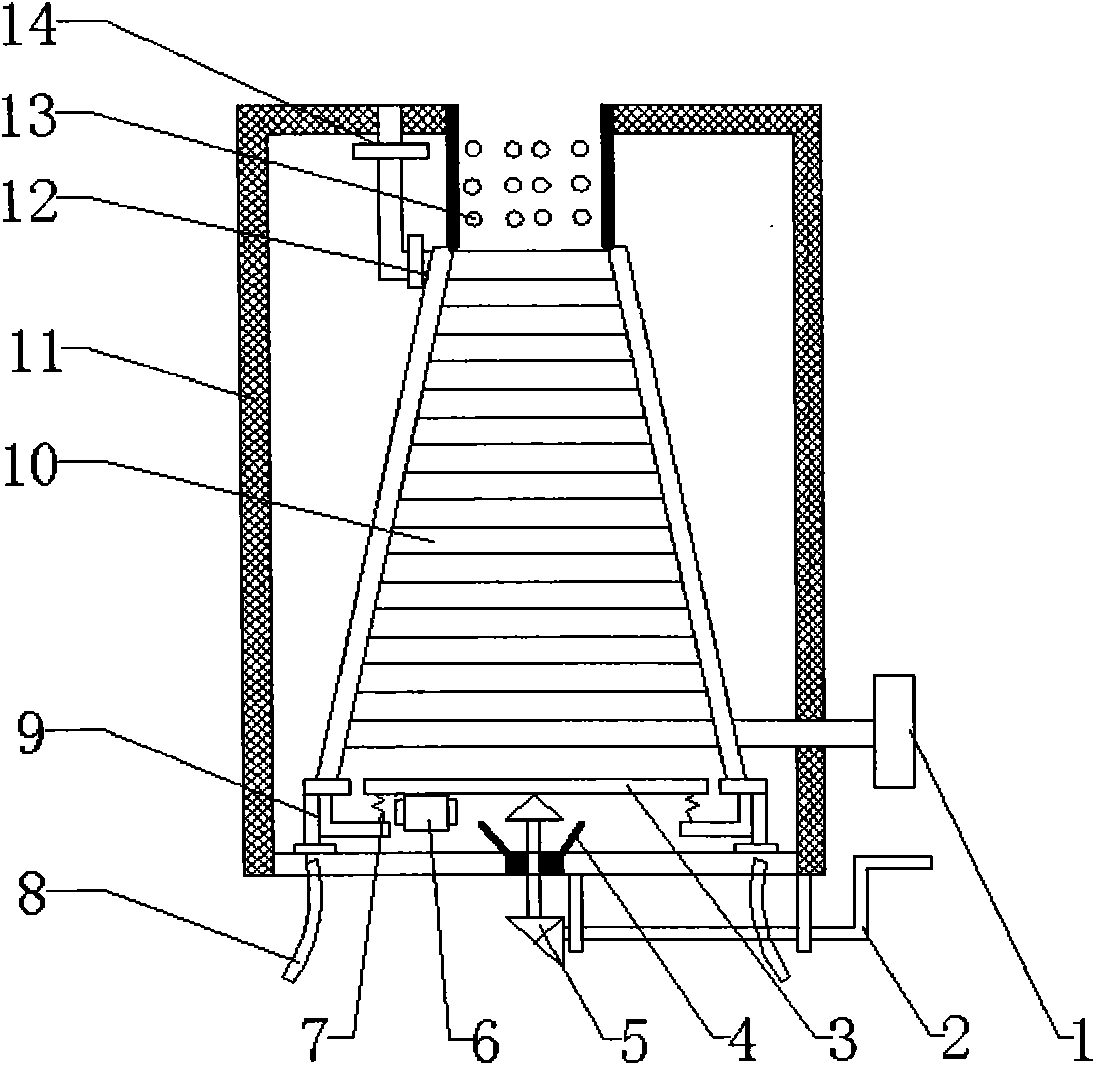

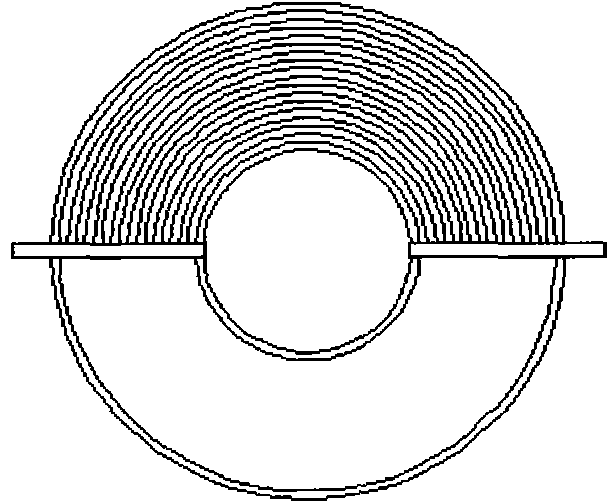

[0047] Such as figure 1As shown, the biomass semi-gasification heating system includes a biomass semi-gasification furnace 11, an energy-saving water tank 16, a heat exchanger 28, a chimney, and an air preheating pipe 15, and the energy-saving water tank 16 is placed in the biomass semi-gasification furnace Above 11, the energy-saving water tank 16 communicates with the first interface 27 of the heat exchanger, and the biomass semi-gasifier 11 communicates with the second interface 29 of the heat exchanger. The chimney runs through the energy-saving water tank 16, one end of the air preheating pipe 15 communicates with the atmosphere through the air inlet, and the other end is provided with an air outlet and is centrally fixed inside the chimney by relying on the air preheating pipe support 20, and passes out from the lower part of the chimney And run through the biomass semi-gasifier. The biomass semi-gasification furnace 11 includes a furnace body supported on the ground by...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com