Fuel chemical chain hydrogen production system and method

A fuel chemistry and hydrogen production system technology, applied in chemical instruments and methods, inorganic chemistry, hydrogen, etc., can solve problems such as difficulty in heat recovery and utilization, reduced hydrogen production efficiency, complex systems, etc., to suppress carbon deposition and widen the temperature window , The effect of high hydrogen production efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

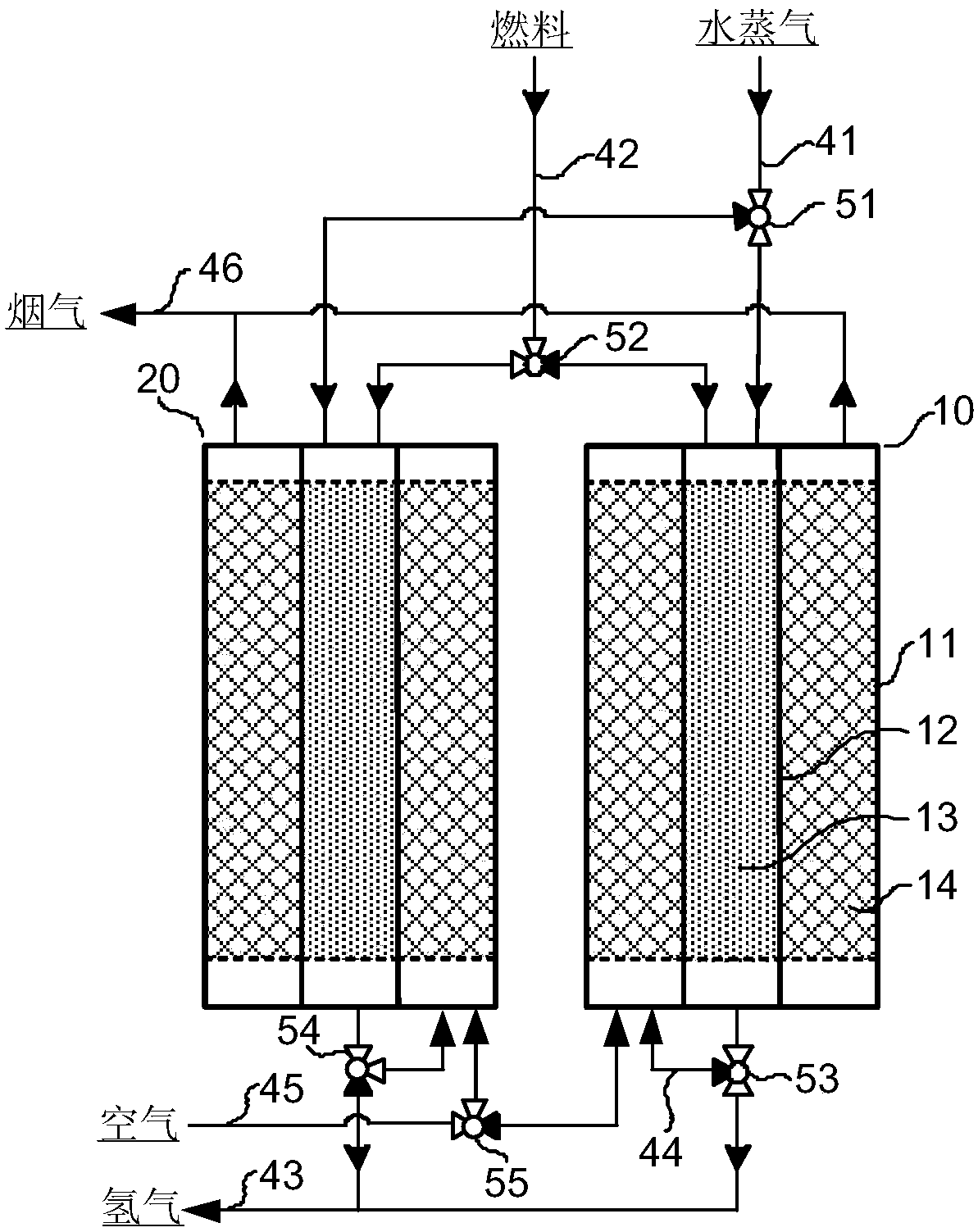

[0052] This embodiment provides a fuel chemical loop hydrogen production system, such as figure 1 shown.

[0053] The fuel chemical looping hydrogen production system provided in this embodiment includes two completely identical chemical looping combustion reactors, namely the first chemical looping combustion reactor 10 and the second chemical looping combustion reactor 20, wherein the two chemical looping combustion The reactors all include an outer tube 11 and an inner tube 12 coaxially arranged with the outer tube, the inner tube is filled with a first oxygen carrier 13, and the interlayer between the outer tube and the inner tube is filled with a second oxygen carrier 14; the inner tube The upper end of the inner tube is connected with a water vapor introduction pipeline 41 and a fuel introduction pipeline 42, and the lower end of the inner tube is connected with a gas outlet pipeline, and the gas outlet pipeline passes through the third three-way valve 53 (or the fourth ...

Embodiment 2

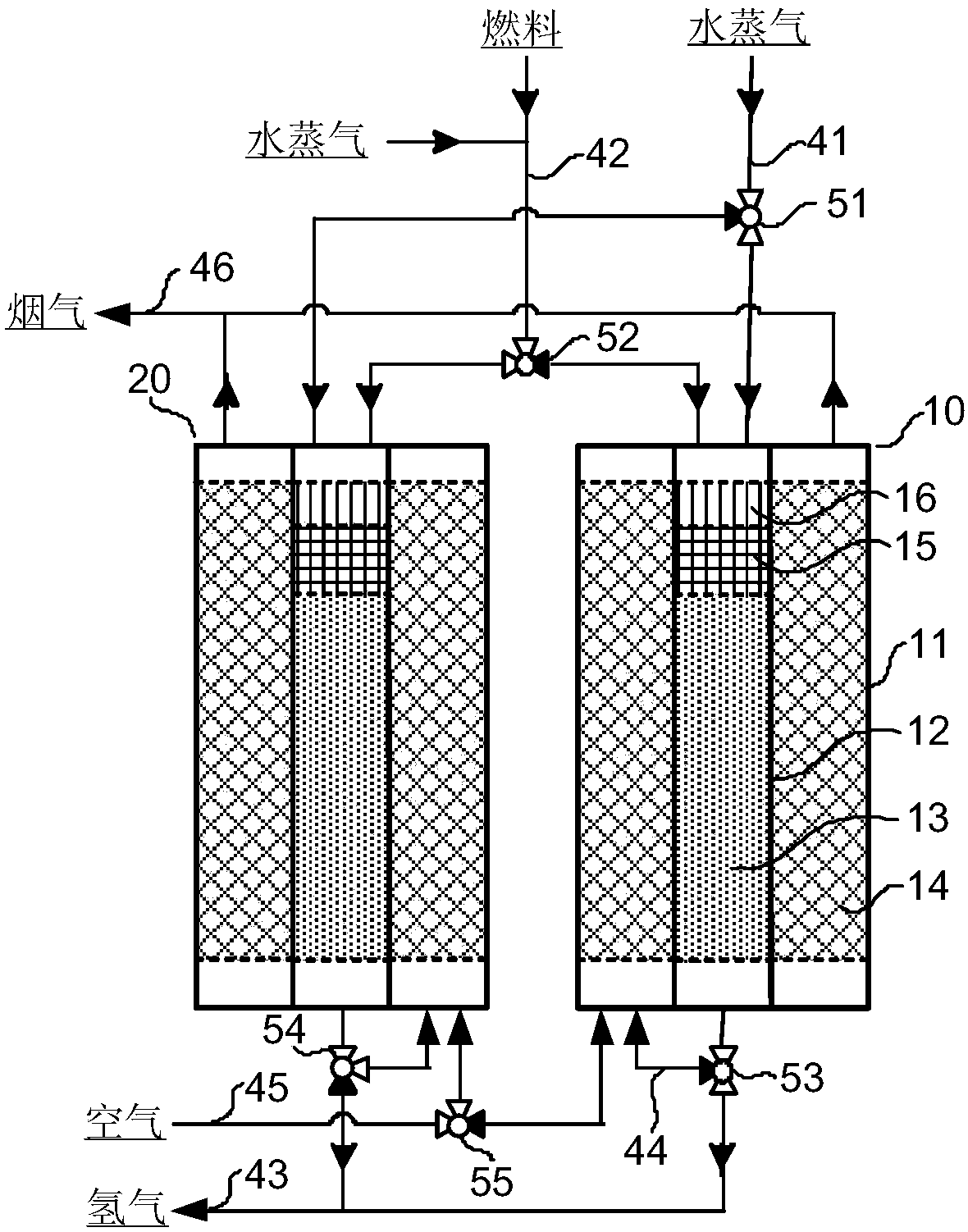

[0057] This embodiment provides a fuel chemical loop hydrogen production system, such as figure 2 shown.

[0058] In the fuel chemical loop hydrogen production system provided in this embodiment, water vapor is added to the fuel, and a steam reforming catalyst 15 is also filled above the first oxygen carrier filling layer to carry out the steam reforming reaction of fuel and CO water vapor Change response. Preferably, the steam reforming catalyst may be a Ni-based reforming catalyst or a Ru-based reforming catalyst.

[0059] In the fuel chemical loop hydrogen production system provided in this embodiment, the top of the first oxygen carrier filling layer is filled with a steam reforming catalyst, so that the fuel and Fe 3 o 4 Before the reaction, the fuel is pre-converted into CO and H with stronger reducing ability through the steam reforming reaction 2 , so that Fe 3 o 4 The temperature required for reduction to FeO is obviously lowered, and the reduction reaction tem...

Embodiment 3

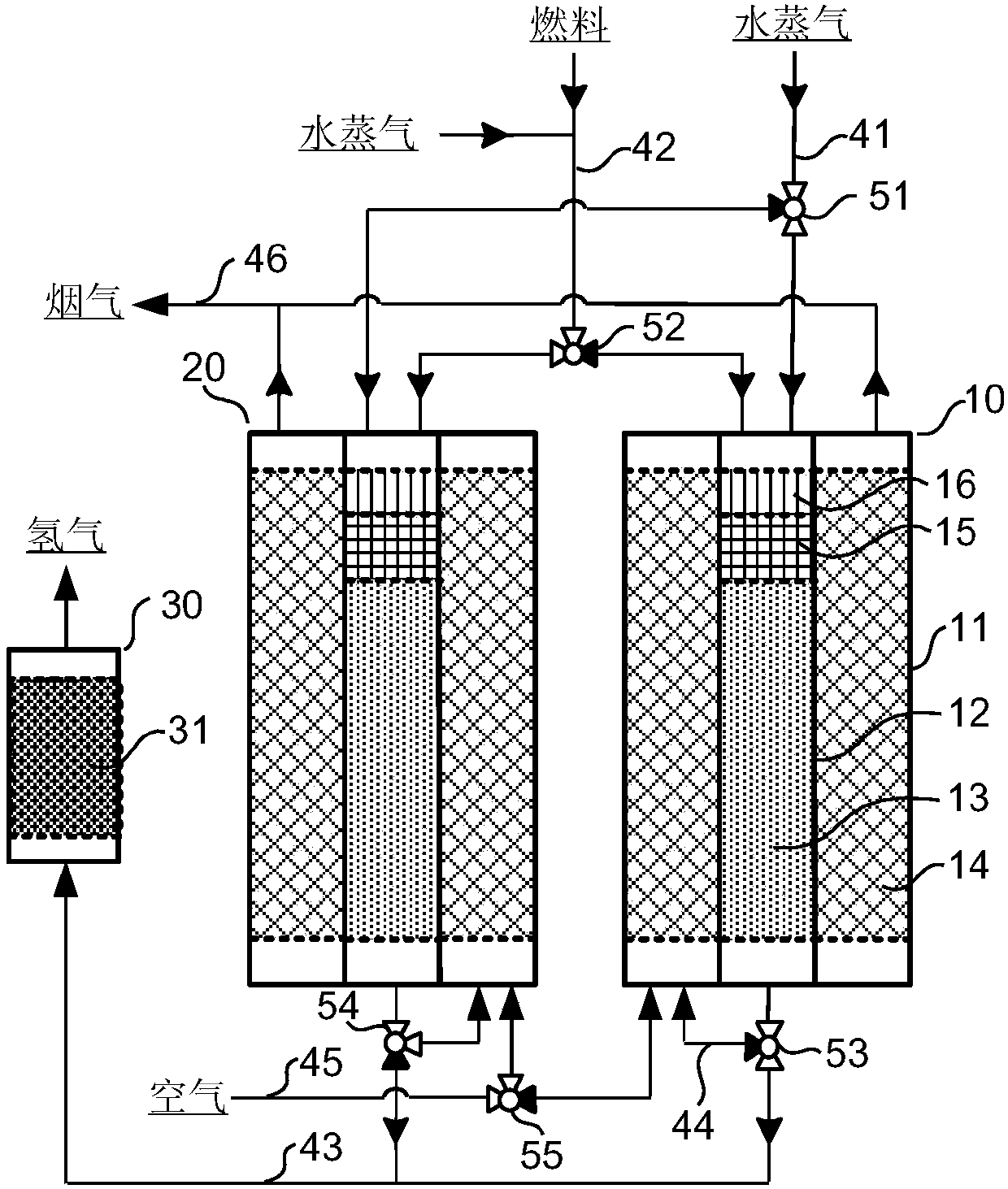

[0063] This embodiment provides a fuel chemical loop hydrogen production system, such as image 3 shown.

[0064] In the fuel chemical chain hydrogen production system provided in this embodiment, a methanation reactor 30 is provided on the hydrogen outlet pipeline, and the methanation catalyst 31 is filled in the methanation reactor.

[0065] In this embodiment, a methanation reactor is installed on the hydrogen outlet pipeline, and a small amount of CO mixed into the hydrogen during switching 2 and CO is converted to H 2 -Harmless CH in PEMFC stack 4 .

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com