Method of measuring micro-amount niobium in steelmaking blast furnace slag

A technology of blast furnace slag and micro-quantity, which is applied in the direction of measuring devices, material analysis by electromagnetic means, instruments, etc., can solve problems such as unsuitable analysis of micro-quantity niobium, unsatisfactory measurement, interference in measurement, etc., to achieve good application effect and eliminate matrix effect, the effect of easy operation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

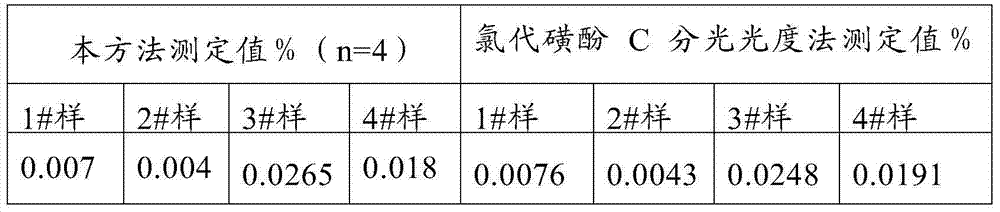

[0053] Blast furnace slag samples were weighed and determined by acid-soluble-chlorosulfonol C spectrophotometry and the above method, respectively, and the results are shown in Table 1.

[0054] Table 1 Sample determination results

[0055]

Embodiment 2

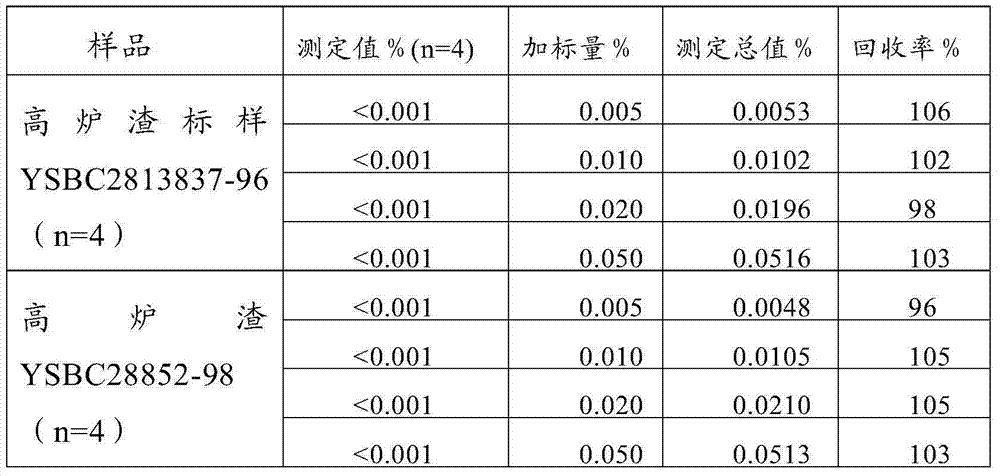

[0056] Embodiment 2: standard addition recovery

[0057]Weigh the niobium-free blast furnace slag standard sample YSBC28851-98, and add niobium standard to the blast furnace slag YSBC28852-98, so that the niobium content is 0.0050%, 0.0100%, 0.020%, and 0.050%, respectively, and measure it according to the above method, and the results are shown in the table 2.

[0058] Table 2 Standard sample spiked recovery determination results

[0059]

[0060] From the data in the above table, it can be calculated that the recovery rate of the addition of niobium is 96%-106%, and the measurement results are accurate, meeting the requirements for the determination of trace amounts of niobium in blast furnace slag.

Embodiment 3

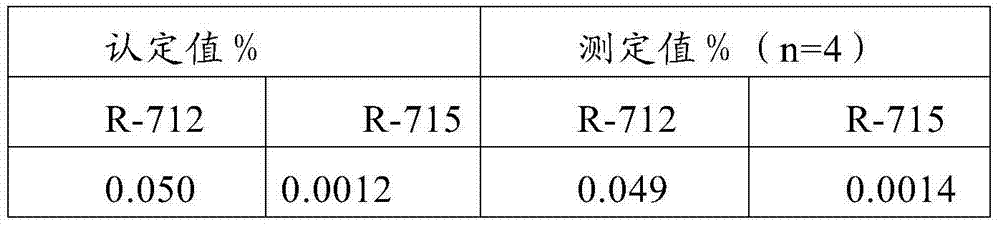

[0062] Select slag standard sample R-712 (Nb 2 o 5 The certified value is 0.066%, and this standard sample exceeds the upper limit of the analytical method by weighing 0.0500g sample), R-715 (Nb 2 o 5 Certified value is 0.042%), measured by the above-mentioned method, the results are shown in Table 3.

[0063] Table 3 Determination results of standard samples

[0064]

[0065] Therefore, the present invention adopts the low-temperature acid dissolution-ICP-MS mass spectrometry method to simultaneously rapidly and accurately measure the content of trace niobium in steelmaking blast furnace slag. The recovery rate and accuracy of this method all meet the detection and analysis requirements, and the linear correlation coefficients of the elements are all between 0.9991 and 0.9999, which has high practicability and wide promotion value.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com