Technique for preparing sodium dimethyl 5-sulfoisophthalate

A technology of dimethyl isophthalate and sodium sulfonate, which is applied in the preparation of sulfonate, organic chemistry, etc., and can solve the problems of many impurities, environmental pollution, and difficult recovery and treatment.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

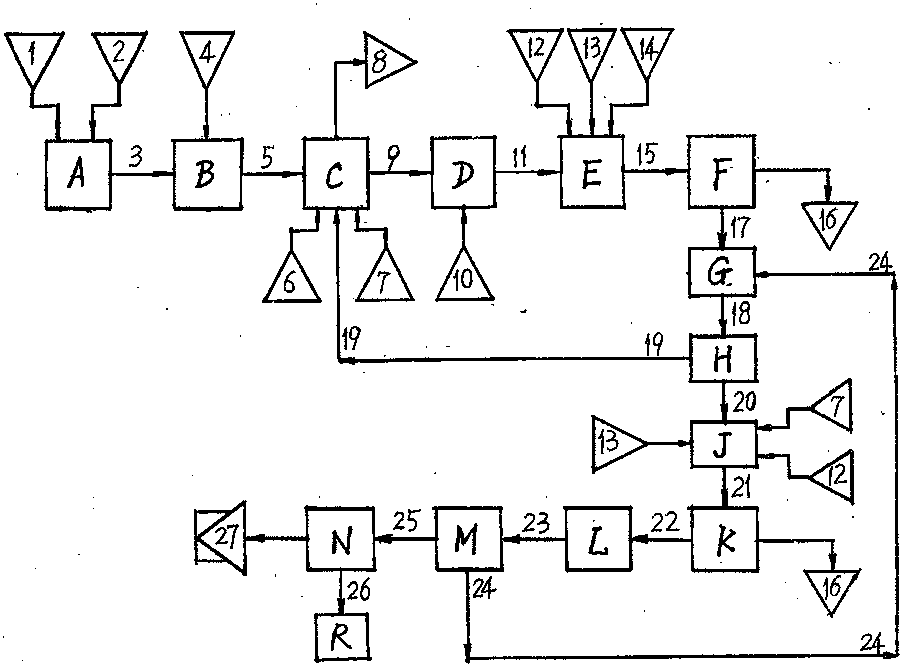

[0008] Specific embodiments of the present invention will be described below in conjunction with the accompanying drawings.

[0009] refer to figure 1, the process for preparing dimethyl isophthalate-5-sodium sulfonate is composed of sulfonation kettle A, esterification kettle B, extraction kettle C, stripping kettle D, decolorization gettering kettle E, filter F, intermediate Crystallization kettle G, centrifugal dehydrator H, thermal melting kettle J, fine filter K, terminal crystallization kettle L, secondary dehydrator M, and dryer N are process equipment, which are connected by pipelines to form a production line. Nicotinic sulfuric acid 2 is the main raw material, after the sulfonation process, esterification process, extraction and stripping process, decolorization and impurity removal and filtration process, intermediate crystallization and dehydration process, hot melting and fine filtration process, terminal crystallization dehydration and drying process Process, ad...

PUM

| Property | Measurement | Unit |

|---|---|---|

| acid value | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com