Method for producing sodium aluminate by treating Bayer-process red mud through andradite one-step alkali thermal method

A technology for Bayer process red mud and calcium iron garnet, which is applied to the field of sodium aluminate production from Bayer process red mud by one-step alkaline heat treatment of calcium iron garnet, can solve the problems of waste of raw materials, high cost, low removal efficiency and the like

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0037] In this embodiment, diaspore Bayer process red mud is used, and the main chemical composition (mass percentage, wt%) is: alumina (Al 2 o 3 ) 21.62%, silicon dioxide (SiO 2 )16.11%, sodium oxide (Na 2 O) 7.08%, calcium oxide (CaO) 16.50%, total iron (TFe) 14.80%, and its aluminum-silicon ratio is 1.34;

[0038] Sodium ferrite is sintered from iron-containing raw materials and industrial caustic soda;

[0039] The caustic concentration in the circulating mother liquor is 240g / L, and the molecular ratio is 25;

[0040] F / A=0.6:1;

[0041] C / S=2.5:1.

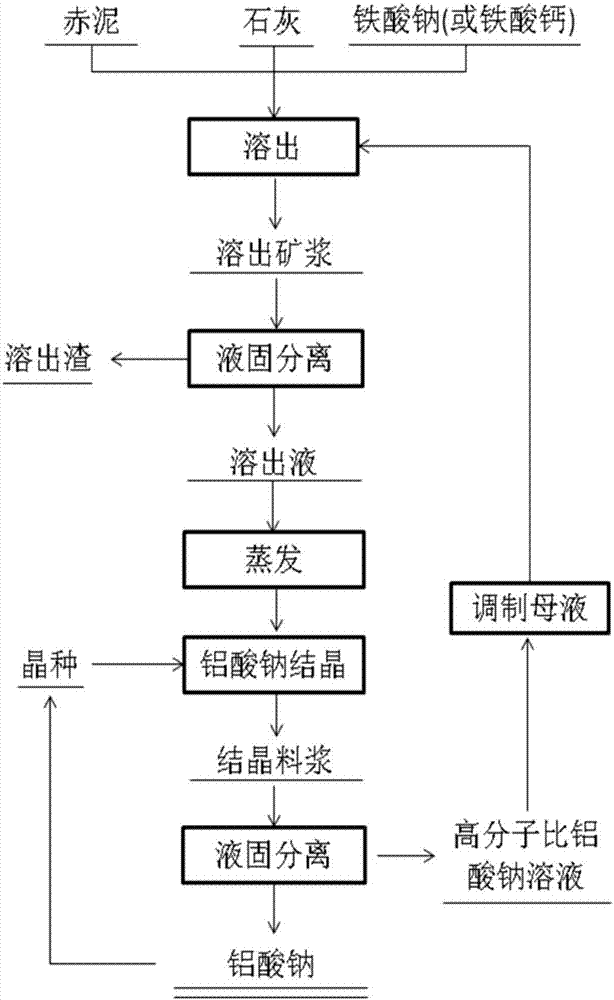

[0042] according to this figure 1 The method for the production of sodium aluminate by the one-step alkali-thermal process of the present invention with andradite red mud of Bayer process as shown:

[0043] S1: After mixing red mud, sodium ferrite and active lime, mix it with circulating mother liquor according to the ratio of L / S=4:1 to prepare raw material slurry;

[0044] S2: The raw material pulp is subjected to alk...

Embodiment 2

[0056] This embodiment adopts Bayer process red mud, and its main chemical composition (mass percentage, wt%) is: alumina (Al 2 o 3 ) 23.35%, silicon dioxide (SiO 2 ) 23.23%, sodium oxide (Na 2 O) 15.61%, calcium oxide (CaO) 0.51%, total iron (TFe) 16.16%, titanium dioxide (TiO 2 )5.37%, and its aluminum-silicon ratio is 1.01;

[0057] Calcium ferrite is sintered from iron-containing raw materials and lime;

[0058] The caustic concentration in the circulating mother liquor is 240g / L, and the molecular ratio is 25;

[0059] F / A=0.5:1;

[0060] C / S=3:1.

[0061] according to this figure 1 The method for the production of sodium aluminate by the one-step alkali-thermal process of the present invention with andradite red mud of Bayer process as shown:

[0062] S1: After mixing red mud, sodium ferrite and lime, mix them with circulating mother liquor according to the ratio of L / S=5:1 to prepare raw material slurry (note: the iron contained in red mud is not included in the...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com