Method for extracting alpha-mangostin from mangosteen fruit peel

A technology of mangostin and mangosteen peel, applied in the direction of pharmaceutical formula, medical preparations containing active ingredients, plant raw materials, etc., can solve the problems of complex process, low yield, long operation time, etc., and achieve simple process and high yield High, short operation time effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

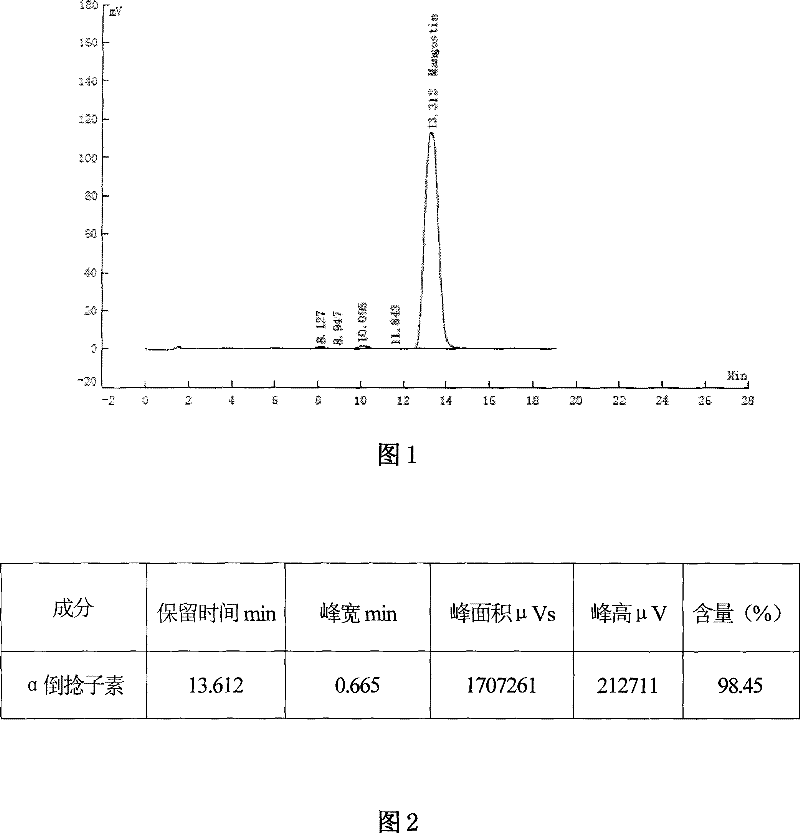

[0065] Take 100 kg of mangosteen peel, wash and crush it, add 5 times the volume of 50% ethanol, extract 3 times at 90°C for 2 hours each time, and collect the first, second and third extraction liquids respectively, and pass each extraction liquid through centrifuge, filter, combine, and under the conditions of temperature of 60°C and pressure of 0.06MPa, concentrate under reduced pressure until there is no alcohol smell to obtain a concentrated solution, add 5 times the volume of ethyl acetate to extract the concentrated solution for 3 times, The extracts were combined, concentrated to 1 / 20 of the original volume, and 2 times the volume of silica gel was added to mix the sample to obtain a mixed sample. The mixed sample and 120 mesh silica gel were packed in a column at a mass ratio of 1:10, and the mixture was mixed with chloroform and ethyl acetate. Mix at a volume ratio of 20:1 to elute and remove impurities, and then mix at a volume ratio of 10:1 to elute the active ingre...

Embodiment 2

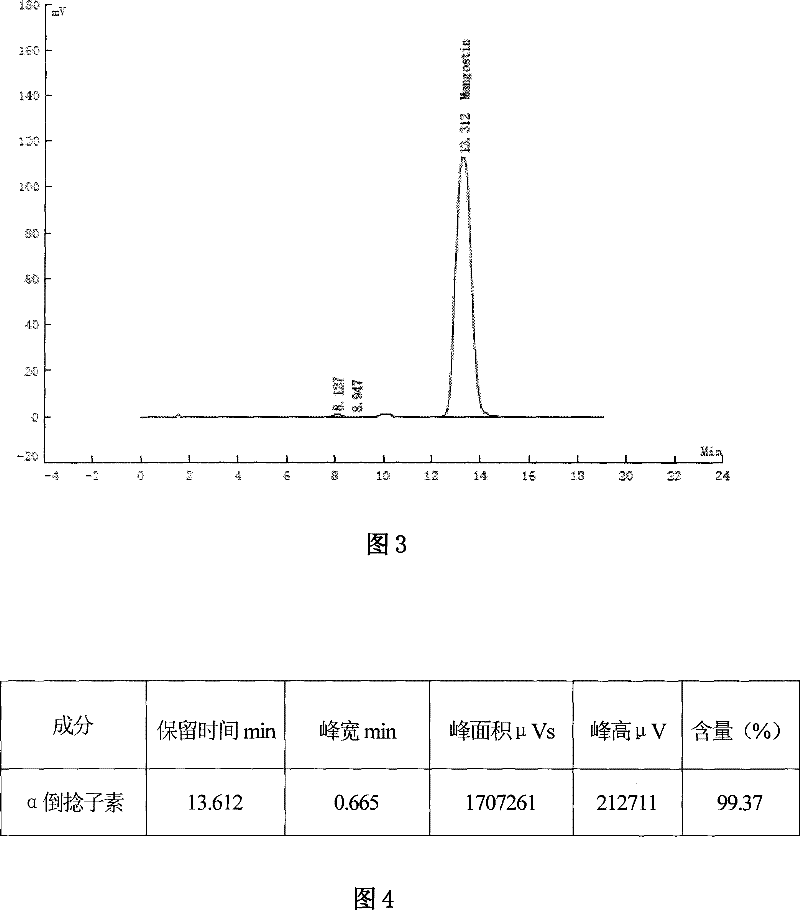

[0067]Take 100kg of mangosteen peel, wash and crush it, add 4 times the volume of 75% ethanol, extract twice at 80°C for 2 hours each time, collect the first, second and third extraction liquids respectively, and pass each extraction liquid through centrifugation Machine centrifugation, filtration, combined, at a temperature of 60°C and a pressure of 0.06MPa, concentrated under reduced pressure until no alcohol smell, to obtain a concentrated solution, adding 5 times the volume of ethyl acetate to extract the concentrated solution 3 times, combined The extract is concentrated to 1 / 20 of the original volume of the specific gravity, and 2 times the volume of silica gel is added to obtain a mixed sample. The mixed sample and 120 mesh silica gel are packed in a column at a mass ratio of 1:10, and the volume ratio of chloroform and acetone is 40:1. 1. After mixing, elute and remove impurities, and then mix according to the volume ratio of 20:1 to elute the active ingredient, and use...

PUM

| Property | Measurement | Unit |

|---|---|---|

| wavelength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com