Gelatin/polyvinyl alcohol composite sponge and preparation method thereof

A technology of polyvinyl alcohol and composite sponge, applied in medical science, absorbent pads, prostheses, etc., to achieve the effect of low cost, simple process, and good viscoelasticity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0025] The preparation method of gelatin / polyvinyl alcohol composite sponge comprises the steps:

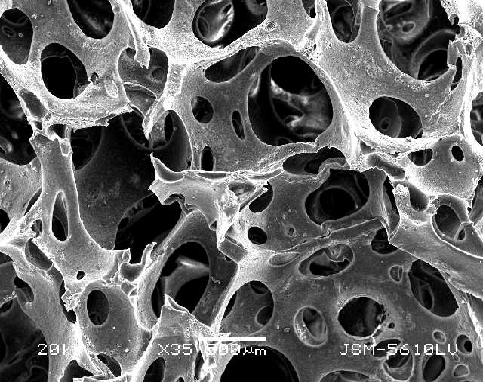

[0026] Add polyvinyl alcohol and gelatin according to the weight percentage of each raw material: 9 wt% polyvinyl alcohol with a degree of polymerization of 1700, 1 wt% gelatin, and 72 wt% water, put them into a three-necked bottle, reflux and dissolve at 90°C for 100 minutes, Pour the solution into a beaker, add 10wt% hydrochloric acid, 7wt% formaldehyde and 1wt% sodium lauryl sulfate, stir and mix evenly, pour the blend into a mold, and thermoform in an oven at 80°C for 10h to obtain gelatin / Polyvinyl alcohol composite sponge. The elongation at break of the obtained gelatin / polyvinyl alcohol composite sponge was 348%, and the water absorption rate was 1261%. The pore structure of the resulting gelatin / polyvinyl alcohol composite sponge is shown in figure 2 . figure 2 shows the internal network structure of the gelatin / polyvinyl alcohol composite sponge, from figure 2 W...

Embodiment 2

[0028] The preparation method of gelatin / polyvinyl alcohol composite sponge comprises the steps:

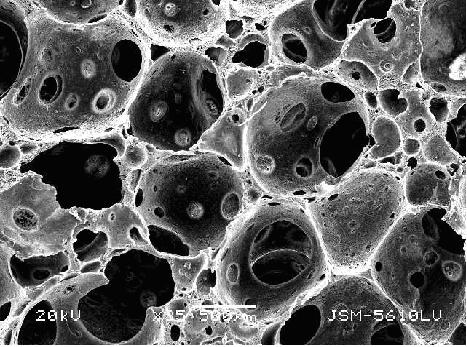

[0029] Add polyvinyl alcohol and gelatin according to the weight percentage of each raw material: 9wt% of polyvinyl alcohol with a degree of polymerization of 1700, 3.86wt% of gelatin, and 69.14wt% of water, put them into a three-necked bottle, reflux and dissolve at 90°C for 100min , pour the solution into a beaker, add 10wt% hydrochloric acid, 7wt% formaldehyde and 1wt% sodium lauryl sulfate, stir and mix evenly, pour the blend into a mold, and thermoform it in an oven at 80°C for 10h to obtain Gelatin / polyvinyl alcohol composite sponge. The elongation at break of the obtained gelatin / polyvinyl alcohol composite sponge was 353%, and the water absorption was 1255%. The pore structure of the resulting gelatin / polyvinyl alcohol composite sponge is shown in image 3 . image 3 shows the internal network structure of the gelatin / polyvinyl alcohol composite sponge, from image 3 ...

Embodiment 3

[0031] The preparation method of gelatin / polyvinyl alcohol sponge comprises the steps:

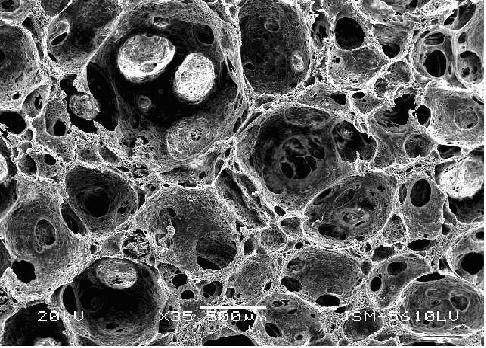

[0032] Add polyvinyl alcohol and gelatin according to the weight percentage of each raw material: 9wt% of polyvinyl alcohol with a degree of polymerization of 1700, 9wt% of gelatin, and 64wt% of water. Pour the solution into a beaker, add 10wt% hydrochloric acid, 7wt% formaldehyde and 1wt% sodium lauryl sulfate, stir and mix evenly, pour the blend into a mold, and thermoform it in an oven at 80°C for 10h to obtain gelatin / Polyvinyl alcohol composite sponge. The elongation at break of the obtained gelatin / polyvinyl alcohol composite sponge was 326%, and the water absorption rate was 1249%. The pore structure of the resulting gelatin / polyvinyl alcohol composite sponge is shown in Figure 4 . Figure 4 shows the internal network structure of the gelatin / polyvinyl alcohol composite sponge, from Figure 4 We can clearly see that the pores of the gelatin / polyvinyl alcohol composite sponge a...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com