Patents

Literature

49results about How to "Reduce sodium chloride content" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Complex flavouring with function of adding saltiness, adding freshness and containing less sodium

ActiveCN101243861AReduce sodium chloride contentSimplify cooking operationsFood shapingFood preparationCooking processLow sodium

The invention discloses a low-sodium functional compound seasoning which can increase the taste of salty and savory. The invention is characterized in that the low-sodium salt is the main raw material on the basis of which one or a plurality of functional nutrients that can increase the taste of savory and salty, and one or a plurality of savory materials are added; then after mixing, stirring, and granulating, the compound seasoning is made. The compound comprises 20 to 80 portions weight of low-sodium salt, 10 to 30 portions weight of functional nutrient and 3 to 15 portions weight of savory materials. Therefore, the compound seasoning has the advantages of effectively reducing the ingestion of NaCI, outstanding flavoring effect and nutrient function. What's more, the invention can be operated simply for the taste of salty, savory and delicious can be got at a time in the process of cooking.

Owner:上海东南清宫食品工业有限公司

Composition for reducing the NaCl content in food products

ActiveUS20100028496A1Reduce sodium chloride contentMilk preparationMeat/fish preservationBiotechnologyOrganic chemistry

The present invention relates to a composition for reducing the sodium chloride content in food products, to processes for the preparation thereof and to uses.

Owner:SYMRISE GMBH & CO KG

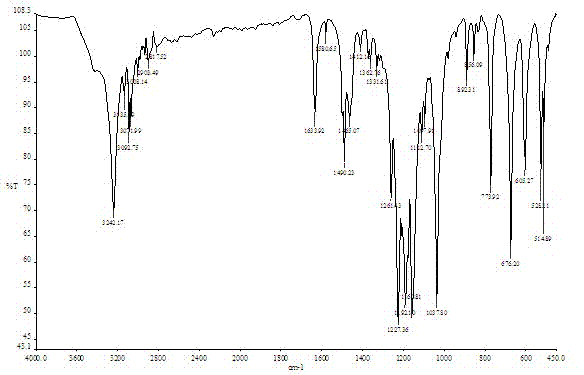

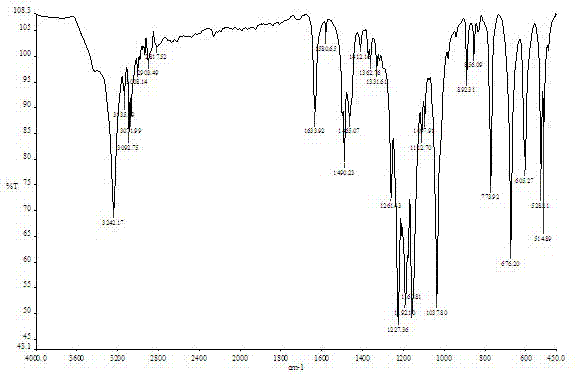

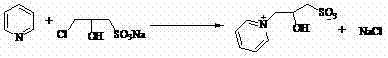

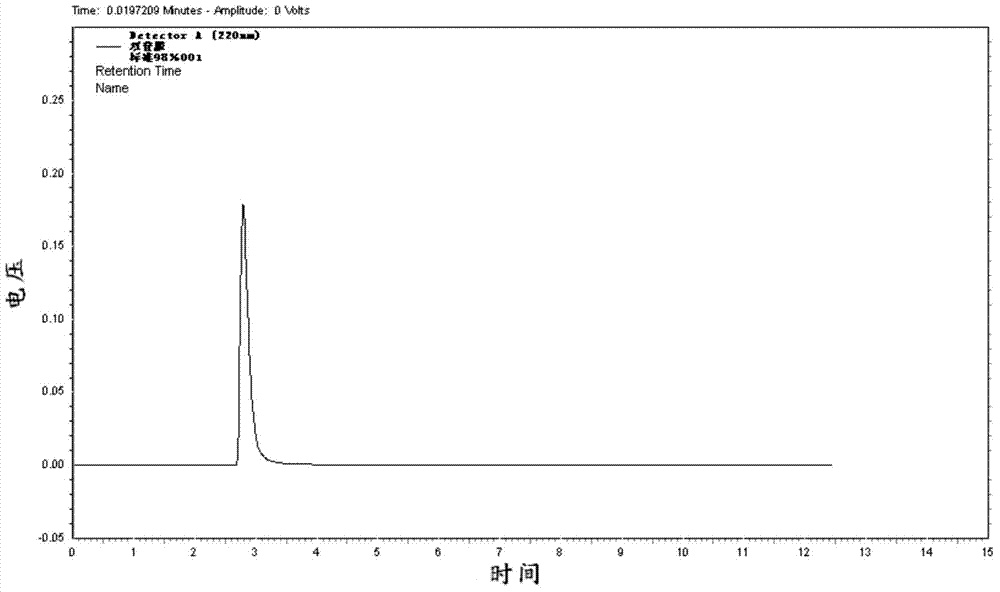

Production method of high-purity PPS-OH

InactiveCN102491942AHigh purityReduce sodium chloride contentOrganic chemistryInorganic saltsOrganic solvent

The invention discloses a production method of high-purity PPS-OH. The production method of the high-purity PPS-OH comprises the following steps of dropwisely adding pyridine into a sodium 3-chloro-2-hydroxypropanesulfonate aqueous solution, carrying out a reflux reaction process for multiple hours, removing the pyridine and water by pressure reduction, carrying out drying to obtain white solids, dissolving the white solids in one or more organic solvents, filtering to remove inorganic salts, adding one or more organic solvents into the filtrate, filtering, and drying to obtain the high-purity PPS-OH. The PPS-OH obtained by the production method has high purity, is convenient for transportation, has low common salt content, does not contain pyridine and has good electroplating effects.

Owner:ZHUZHOU TIMES ELECTRIC INSULATION

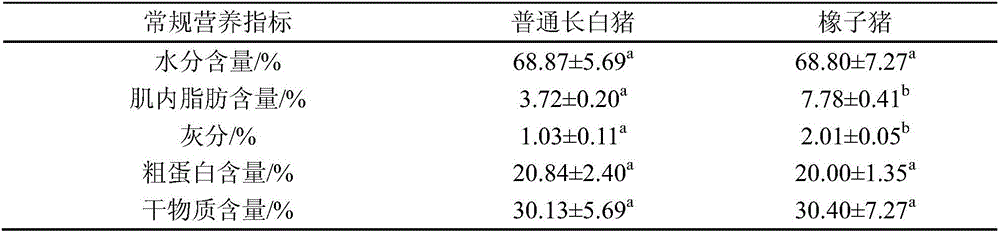

Enhanced high-temperature curing method with synergism of low salt and K salt substitution for producing dry-cured hams of acorn pigs

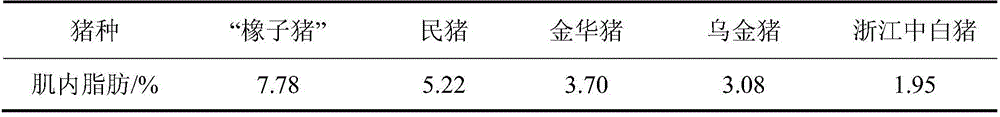

ActiveCN106035603AIncrease productivityReduce sodium chloride contentMeat/fish preservation by shapingClimate change adaptationFlavorAcorn

The invention relates to an enhanced high-temperature curing method with synergism of low salt and K salt substitution for producing dry-cured hams of acorn pigs and belongs to the technical field of deep processing of animal products. The method comprises the following steps: hybridizing local black pigs with Duroc, breeding pigs, taking legs of acorn pigs fed by taking acorns as main feeds as the raw materials, airing, fermenting and curing by using a modern enhanced high-temperature curing process for salting the legs with synergism of low salt and K salt which partially substitutes the salt, carrying out short-time enhanced high-temperature pretreatment after the salting is completed, carrying out anti-oxidization coating treatment on the surface of the hams in the middle period of fermenting and curing, and developing to obtain novel products of dry-cured hams of acorn pigs. The content of sodium chloride in the hams can be obviously reduced; meanwhile, the processing time of the hams is shortened from 10-12 months of the conventional dry-cured hams to 5-6 months through the enhanced high-temperature curing process; the flavor and the quality of the hams are obviously improved. Through the method, the production efficiency of the dry-cured hams is greatly improved; the flavor and the quality of the conventional hams are retained and developed; the characteristics of the process which breaks through the international process and the conventional process and is characterized by fermenting low-salt hams under high temperature are highlighted; the hams can more meet the requirements on health, nutrition and flavor of consumers in the modern society, and have broad market prospects.

Owner:NANJING AGRICULTURAL UNIVERSITY +1

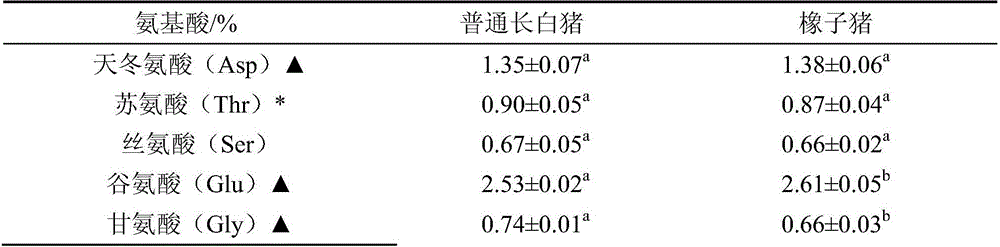

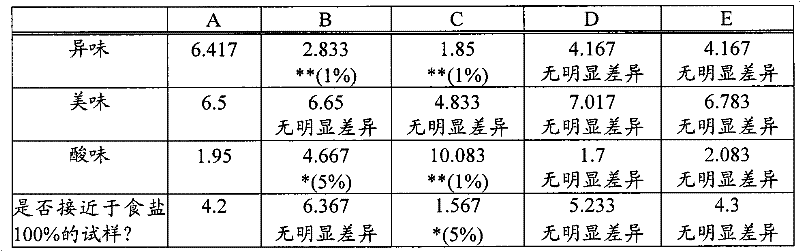

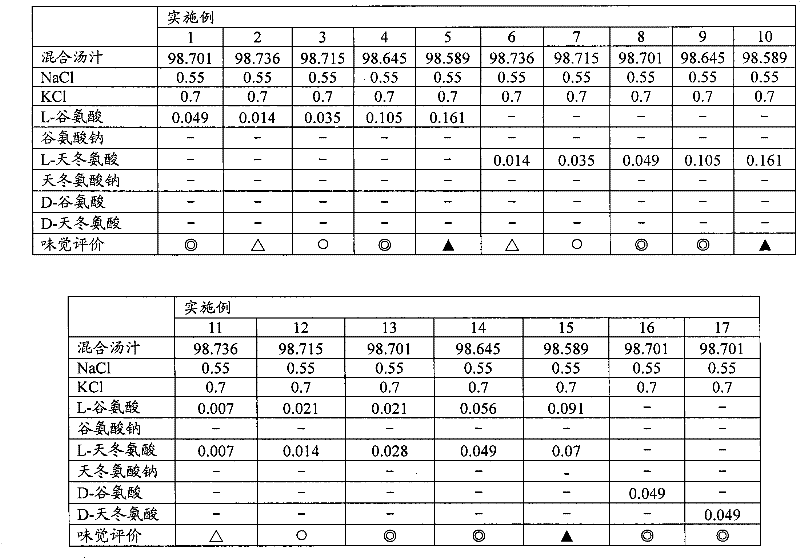

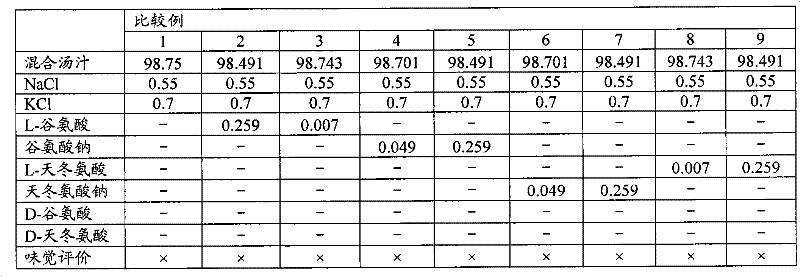

Food composition having strengthened or enhanced saltiness and potassium chloride-containing composition having suppressed offensive taste

InactiveCN102548429AReduce sodium chloride contentReduce contentFood preparationAcetic acidSalty taste

Disclosed are a means for strengthening or enhancing the saltiness of sodium chloride contained in a food composition and a means for suppressing the offensive taste of a composition containing potassium chloride. A food composition containing sodium chloride the saltiness of which is strengthened or enhanced by adding potassium chloride together with acetic acid and / or lactic acid thereto. A composition containing potassium chloride the potassium-origin offensive taste of which is suppressed by adding at least one of glutamic acid and aspartic acid thereto.

Owner:HOUSE FOOD IND CO LTD

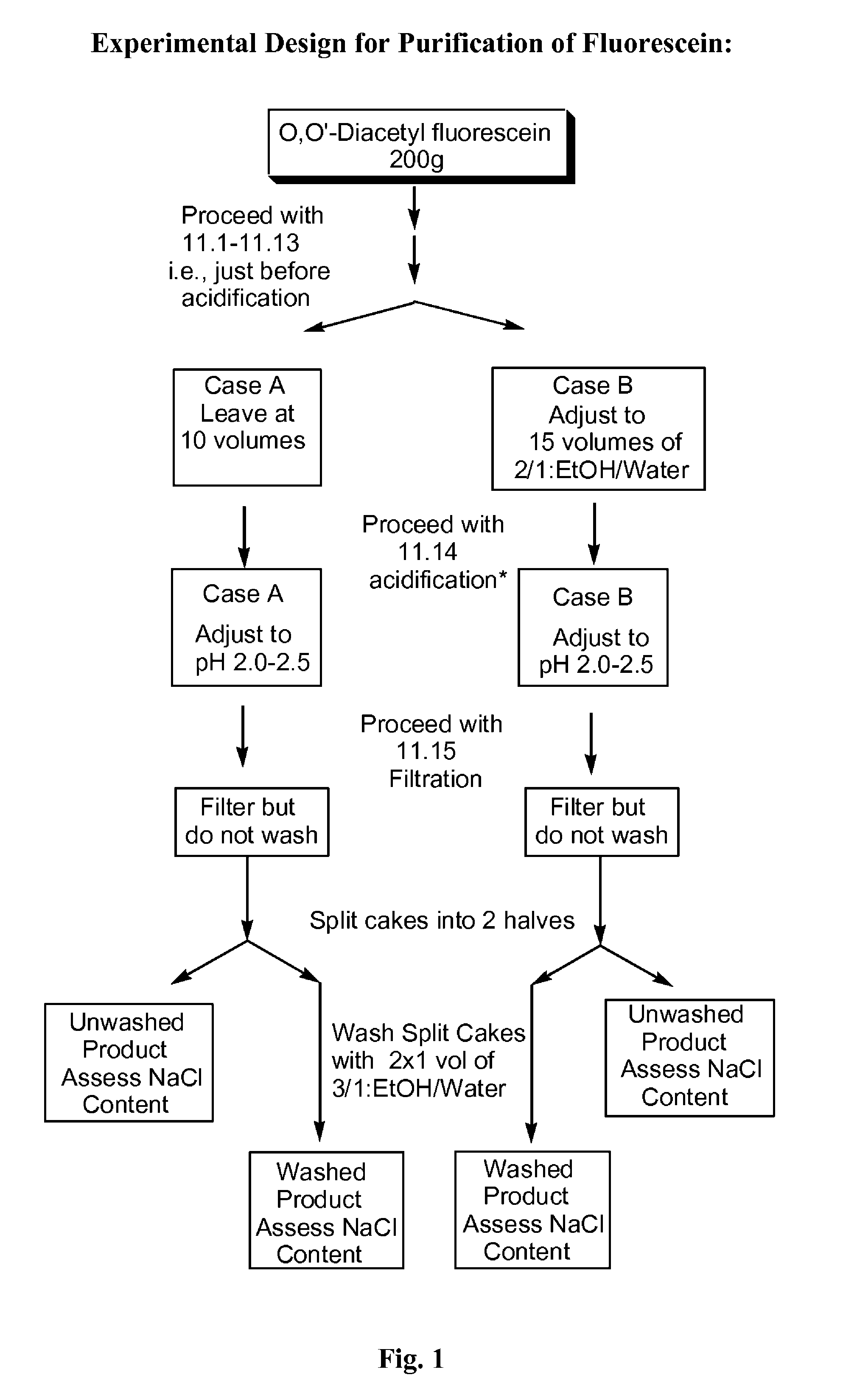

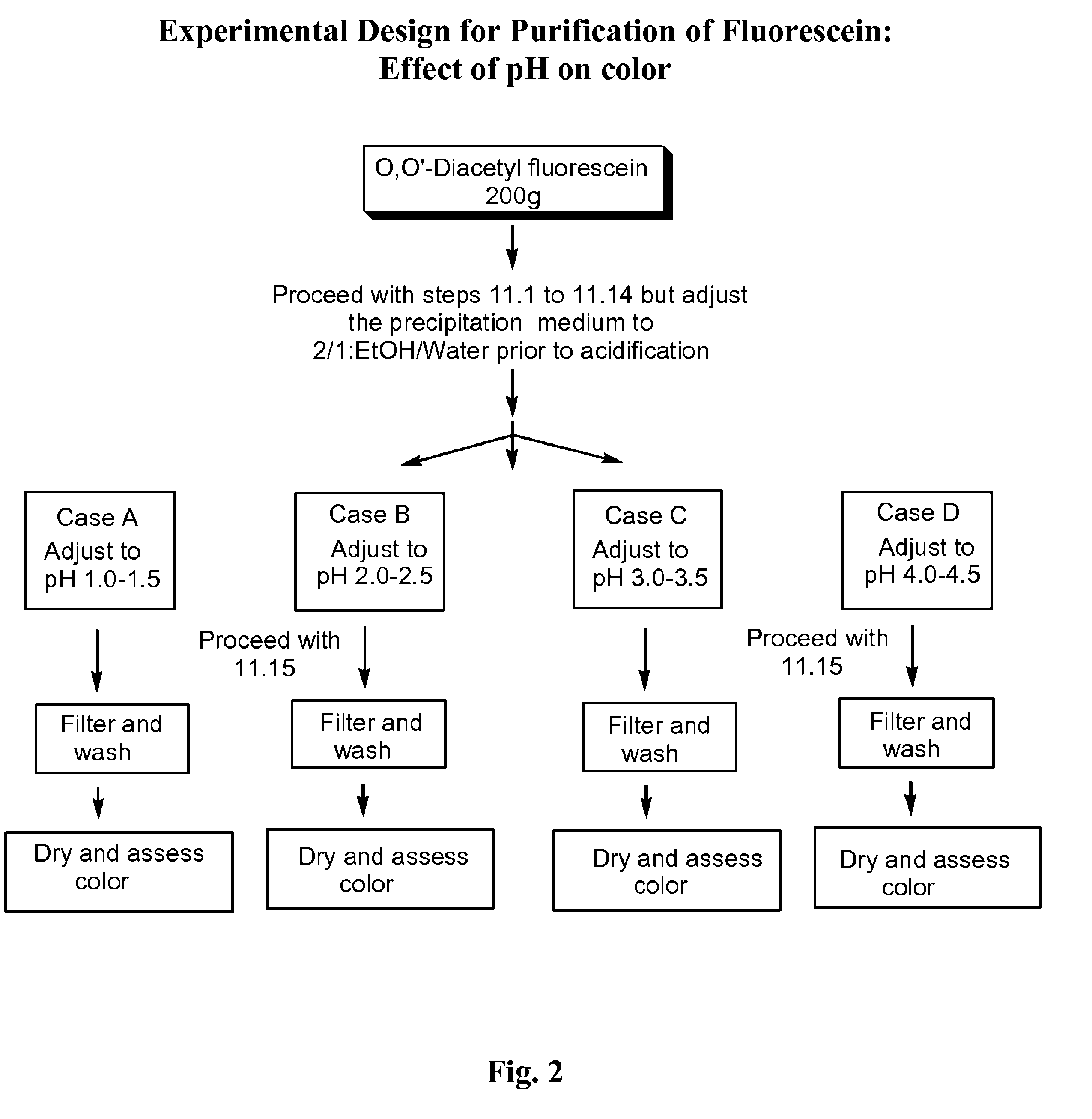

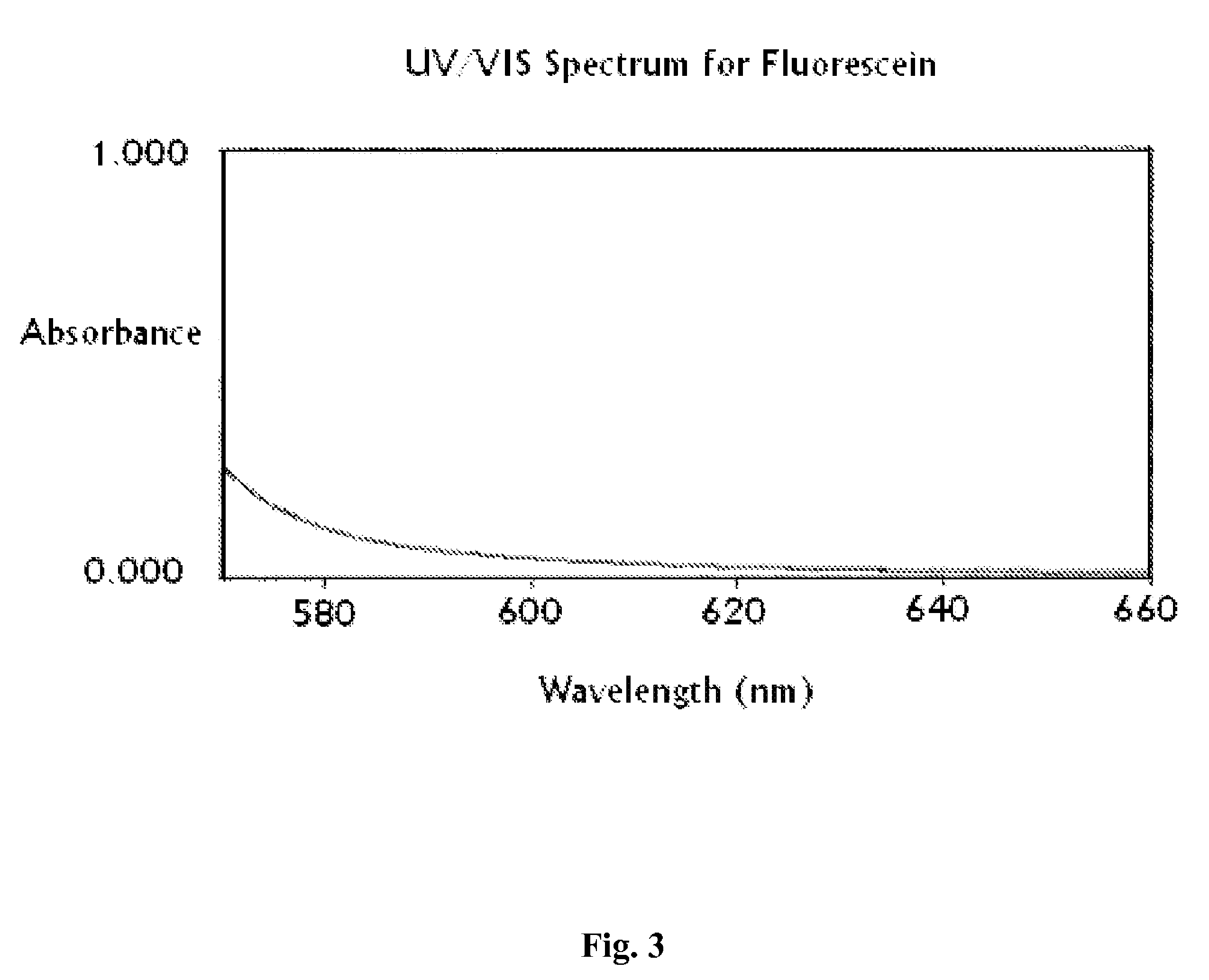

Substantially pure fluorescein

The present invention is directed to an improved process for producing substantially pure fluorescein, as well as to substantially pure fluorescein compositions prepared by the process. The invention is particularly directed to the provision of pharmaceutical compositions for use in angiography. The substantially pure fluorescein produced by the process of the present invention is low in color, low in sodium chloride content, and substantially free of pyridine.

Owner:ALCON INC

Food composition with reinforced or enhanced salty taste and composition containing potassium chloride with suppressed offensive taste

InactiveUS20120201945A1Reduce sodium chloride contentEnhanced salty tasteFood preparationChloride sodiumLactic acid

This invention provides a means for reinforcing or enhancing the salty taste of sodium chloride in a food composition and a means for suppressing the offensive taste in a composition containing potassium chloride. This invention relates to a food composition with a reinforced or enhanced salty taste realized with the addition of potassium chloride and acetic acid and / or lactic acid into a food composition containing sodium chloride. This invention also relates to a composition supplemented with potassium chloride capable of suppressing an offensive taste originating from potassium to which at least one selected from glutamic acid and aspartic acid has been added.

Owner:HOUSE FOOD IND CO LTD

Production method of low-salt low-nitrite sauced beef

InactiveCN108184976ALong storage timeAdd lessMeat/fish preservation by heatingNatural extract food ingredientsNitrosamineSodium nitrite

The invention discloses a production method of low-salt low-nitrite sauced beef. The method comprises the following steps: raw material treatment, preparation of spice essential oil, preparation of spice injection, injecting, rolling, standing and pickling, cooking, and vacuum packaging. Compared with the prior art, the method has the following beneficial effects: the method uses composite salt toreplace pure sodium chloride used in sauced beef, so that the sodium chloride content is reduced by 20 percent or above; the method uses monascus color and nisin to replace part of sodium nitrite, sothat the addition amount of nitrite is reduced by 30 percent; the method adopts ascorbic acid to prevent nitrosamines from forming, and the toxicity of nitrite is further reduced; the method uses thespice essential oil for seasoning so as to control the flavor of the sauced beef more accurately; and a high-temperature cooking process prolongs the storage time of the sauced beef, and improves production efficiency at the same time.

Owner:河南伊赛牛肉股份有限公司

Compound low sodium salt and preparation method thereof

PendingCN107156773ADoes not affect saltinessSavory GuaranteedFood ingredient as taste affecting agentFood shapingRaw materialCalcium

The present invention provides a preparation method of compound low sodium salt. The preparation method comprises the following steps: firstly, potassium chloride, a flavor masking agent and maltodextrin are mixed to obtain flavor masked potassium chloride; then the obtained flavor masked potassium chloride is mixed with calcium source, amino acids, sodium glutamate and sodium chloride to obtain the compound low sodium salt; and wherein the amino acids comprise alanine and uses amounts of each of the raw materials are defined. Firstly, the potassium chloride is mixed with the flavor masking agent and maltodextrin. Under a function of the flavor masking agent carrier of the maltodextrin, the maltodextrin is combined with the flavor masking agent. The flavor masking agent realizes a masking of a bitter mouthfeel of the potassium chloride, is then combined with the calcium source, amino acids, sodium glutamate and sodium chloride, effectively avoids the masking of the own salty taste of the sodium chloride, ensures the salty taste of the added sodium chloride, effectively lowers sodium chloride content and at the same time ensures the salty taste of the sodium chloride.

Owner:NORTHEAST AGRICULTURAL UNIVERSITY

Non-bitter low-sodium umami salt and preparation method thereof

InactiveCN108740961AInhibition of growth and reproductionKeep freshInorganic compound food ingredientsGluconic acidLow sodium

The invention discloses non-bitter low-sodium umami salt. The non-bitter low-sodium umami salt is prepared from the following components in parts by weight: 45 to 50 parts of edible potassium chloride, 35 to 45 parts of edible sodium chloride, 1 to 10 parts of trehalose, 1 to 10 parts of disodium malate, 1 to 15 parts of sodium gluconate and 0.1 to 5 parts of L-alanine. The invention also discloses a preparation method of the non-bitter low-sodium umami salt. According to the non-bitter low-sodium umami salt disclosed by the invention, the salinity and the umami of salt can also be kept or increased while a bitter taste and the content of sodium chloride are reduced; the sodium gluconate and the disodium malate coordinate with each other to play a salinity increasing role, and the trehalose, the disodium malate, the sodium gluconate and the L-alanine can coordinate with each other to play a umami increasing role, so that the salinity and the umami are both remarkably increased; compared with the edible sodium chloride, the content of sodium chloride is reduced by 50 percent or above, and the intake of sodium is greatly reduced.

Owner:YIYANTANG YINGCHENG HEALTH SALT MFG

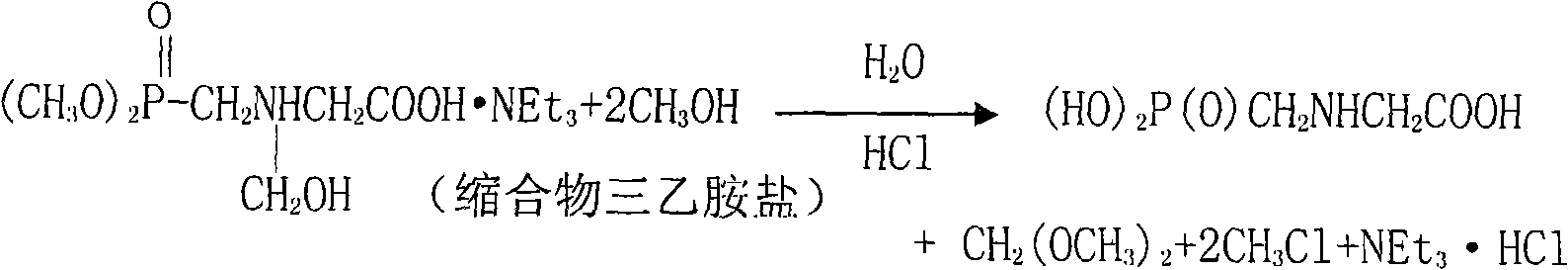

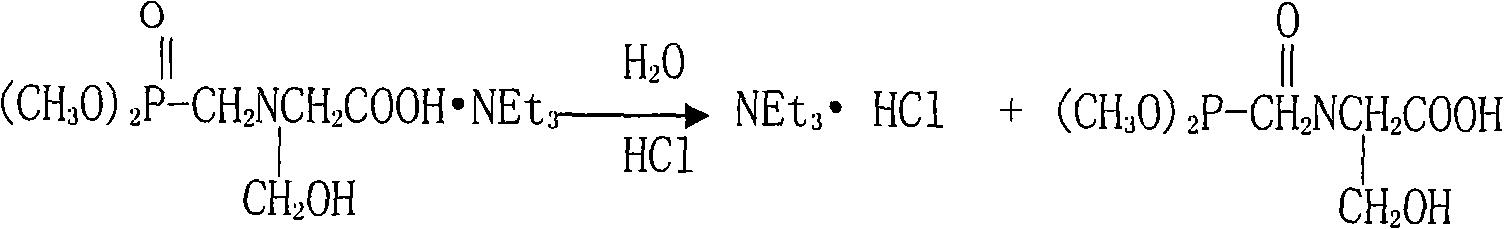

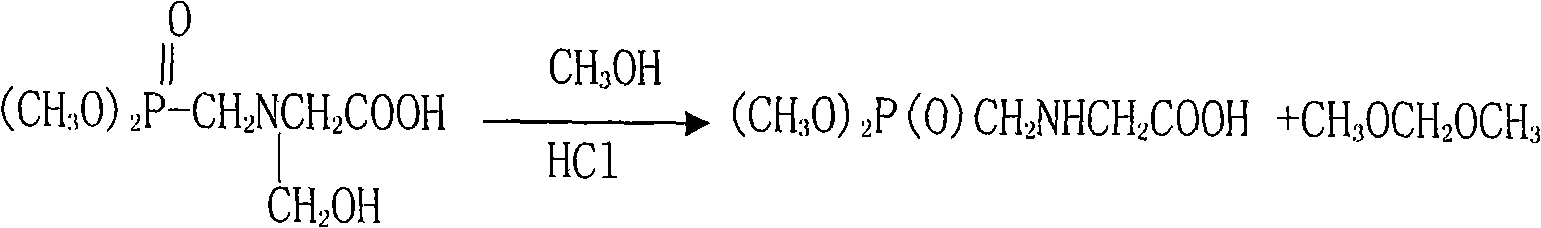

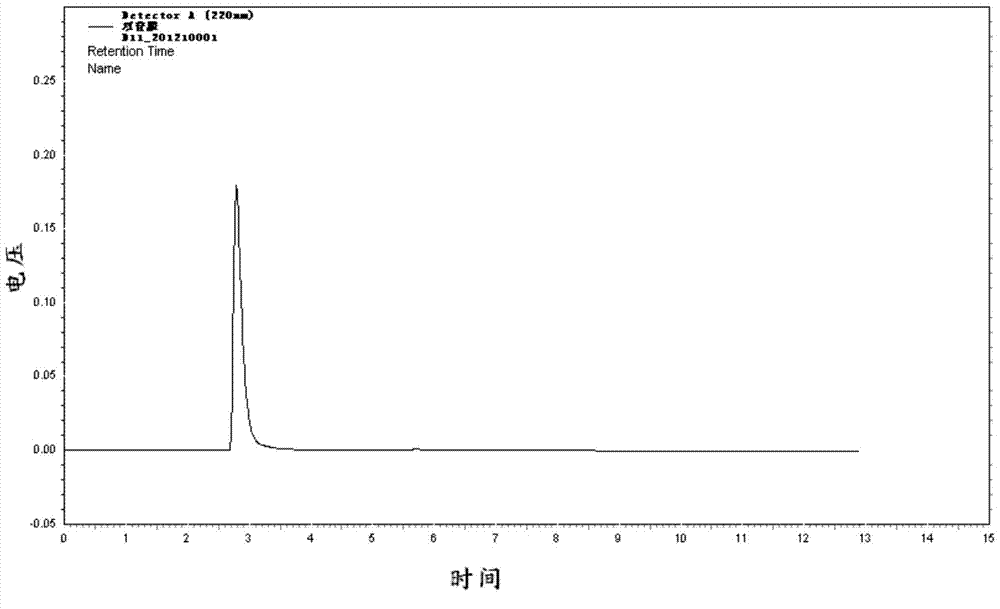

Hydrolyzation post-processing technique during preparation of glyphosate through glycin method

ActiveCN101671363AIncrease surface areaShorten the timeGroup 5/15 element organic compoundsDistillationHydrolysis

The invention relates to a hydrolyzation post-processing technique during preparation of glyphosate through a glycin method, which includes the steps of implementing reduced pressure distillation andseparation to a hydrolyzation liquor under the temperature between 80 and 110 DEG C and the pressure equal to or less than 0.05MPa after the condensation reaction and hydrolysis reaction for preparingglyphosate through the glycin method are finished, depickling and then crystallizing to obtain the glyphosate products. The hydrolyzation post-processing technique during preparation of glyphosate through the glycin method recovers hydrochloric acid by reducing the pressure, which can lead the recovery rate of hydrochloric acid to be more than 4 percent; and hot water is added for crystallizing after the hydrochloric acid is removed, thus effectively improving the availability factor of a crystallization kettle; and meanwhile, as no caustic soda liquor is added during hydrolyzation, the totalamount of a mother liquor and the content of sodium chloride are reduced as well, the energy consumption for recovering triethylamine through rectifying the mother liquor is reduced, and the total yield of the finally obtained solid glyphosate reaches 73-75 percent.

Owner:SICHUAN LESHAN FUHUA TONGDA AGRO-CHEM TECH CO LTD

Selenium-rich chicken essence seasoning containing wild fungi and preparation method of selenium-rich chicken essence seasoning

InactiveCN106616787AAvoid obesity worriesReduce contentFood scienceFood additiveTricholoma matsutake

The invention relates to selenium-rich chicken essence seasoning containing wild fungi and a preparation method of the selenium-rich chicken essence seasoning and belongs to the technical field of food additives. According to the selenium-rich chicken essence seasoning containing wild fungi, holy basil, tricholoma matsutake powder, russula vinosa powder, truffle powder, thelephora ganbajun zang powder and an enzymatic hydrolysate form main delicate flavor, then, roxburgh rose juice and Stanleya pinnata are used for correcting the delicate flavor, besides, disodium 5'-ribonucleotide, xylose and low-sodium salt are compounded, so that the chicken essence seasoning has unique flavor, is fragrant and delicious and contains rich nutrients; meanwhile, through compounding of the thelephora ganbajun zang powder and the Stanleya pinnata, the selenium content of the product is greatly increased, and a good health-care function is realized. Besides, the content of fat and protein in the chicken essence seasoning is greatly reduced, worry of an eater about obesity is avoided, and the selenium-rich chicken essence seasoning is easy to popularize and apply.

Owner:赵站锋

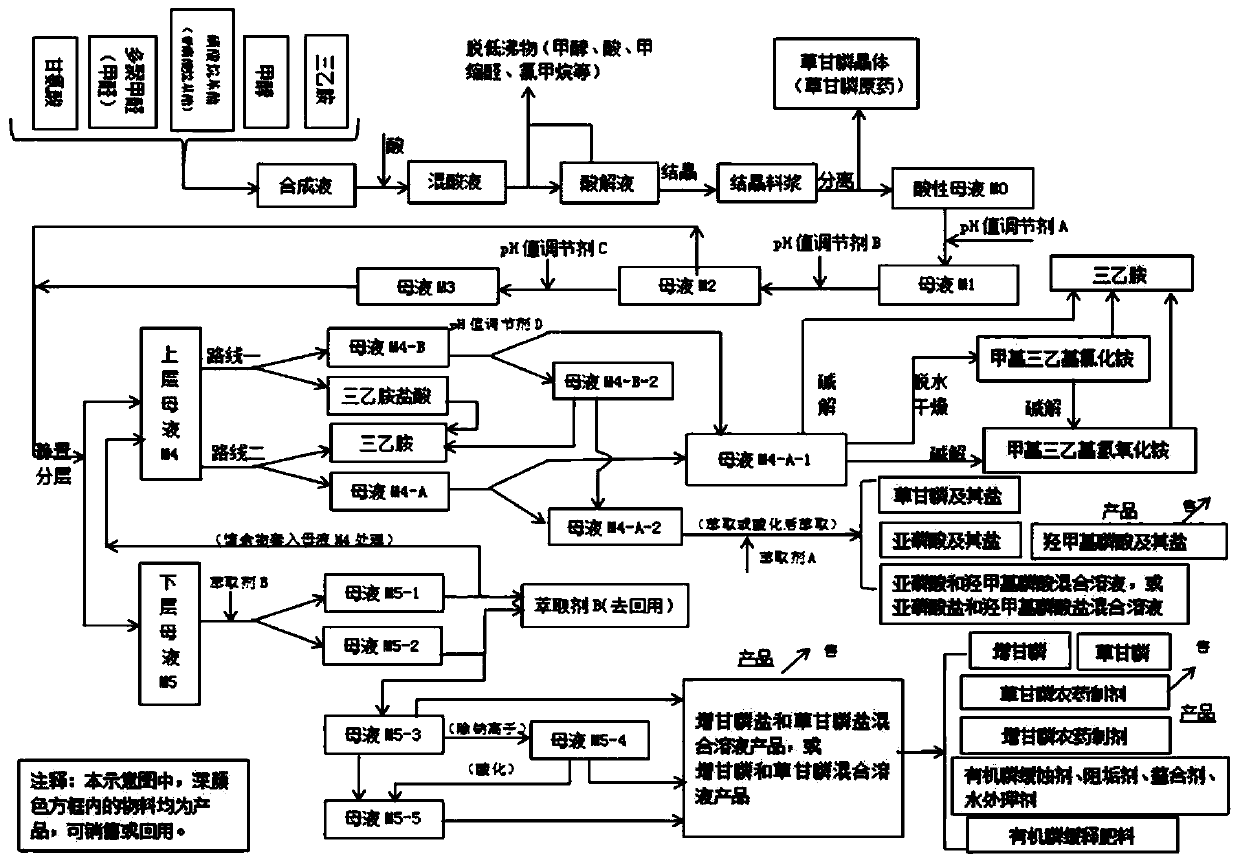

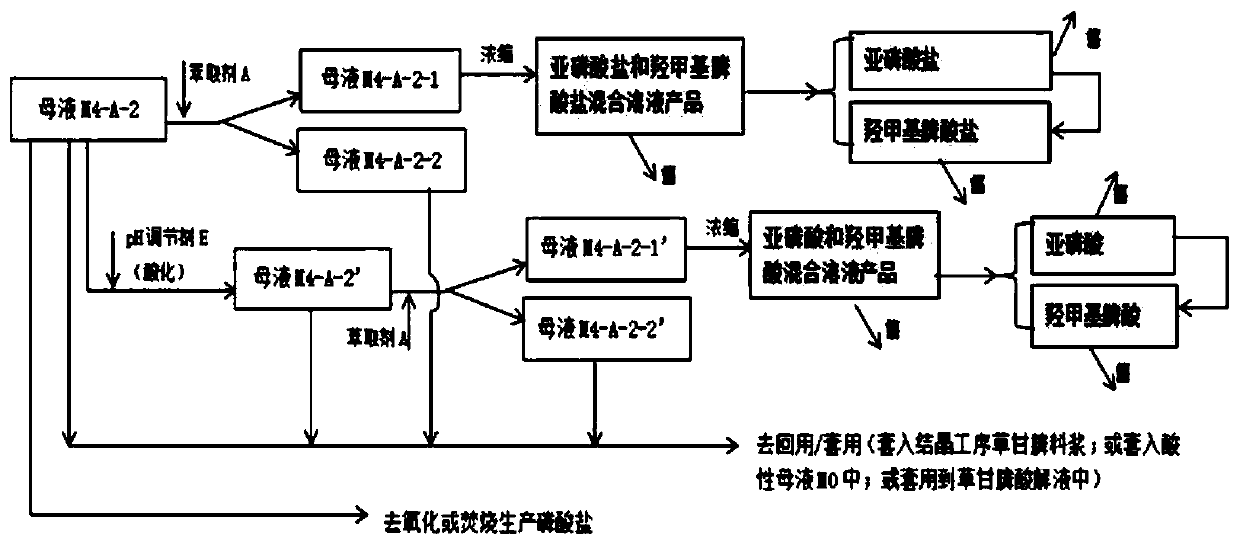

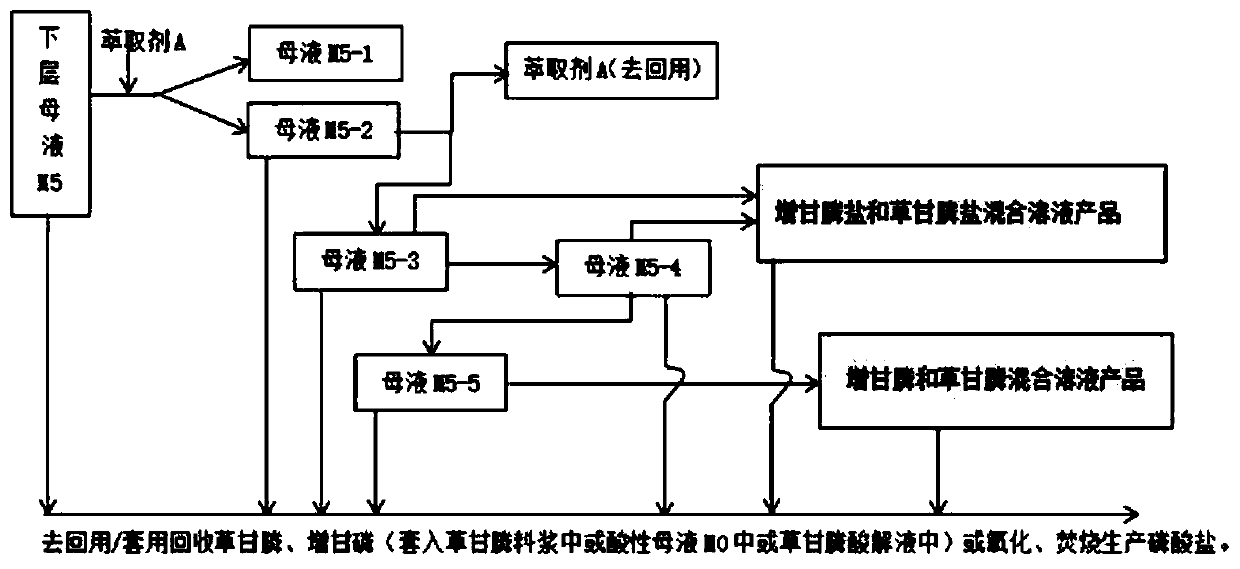

Glyphosate mother liquor comprehensive treatment and resource recycling method

PendingCN111333519AReduce volume and handling costsLess impuritiesAmino compound purification/separationGroup 5/15 element organic compoundsPhosphorous acidPulp and paper industry

The invention discloses a glyphosate mother liquor comprehensive treatment and resource recycling method which comprises the following steps: adding a pH value regulator into acidic mother liquor M0,standing for layering, and separating the solution to obtain mother liquor M4 at the upper layer and mother liquor M5 at the lower layer; the mother liquor M4 and the mother liquor M5 are treated andapplied, triethylamine hydrochloride, triethylamine, chloride salt, methyltriethylammonium chloride, phosphorous acid or salt thereof, hydroxymethylphosphonic acid or salt thereof, glyphosate or saltthereof, glyphosate or salt thereof and glyphosate or salt thereof are recovered from the mother liquor M4 and the mother liquor M5, and are respectively and correspondingly converted into products with higher additional values for utilization. The glyphosate mother liquor comprehensive treatment and resource recycling method has the advantages that the emission is reduced from the source; the method reduces the total amount and treatment load of the glyphosate mother liquor, reduces environmental pollution, realizes reasonable recycling and appreciation of resources, improves economic benefits, is environment-friendly, outstanding in economic benefits and good in technical implementation effect, and is suitable for large-scale industrial application.

Owner:陈兴华

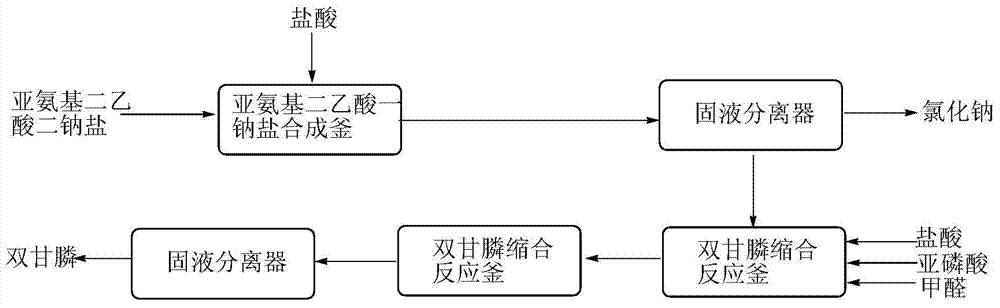

Preparation method of N-(phosphonomethyl) iminodiacetic acid

InactiveCN103613615APrevent precipitationLow viscosityGroup 5/15 element organic compoundsPhosphorous acidSolubility

The invention provides a preparation method of N-(phosphonomethyl) iminodiacetic acid. The preparation method comprises the steps of enabling disodium iminodiacetate to react with hydrochloric acid to obtain a solution containing monosodium iminodiacetate and sodium chloride; concentrating the solution containing monosodium iminodiacetate and sodium chloride, heating and filtering to obtain a sodium chloride solid and filtrate; mixing the filtrate with hydrochloric acid and phosphorous acid, heating, then adding formaldehyde and reacting to obtain N-(phosphonomethyl) iminodiacetic acid. As monosodium iminodiacetate has relatively large solubility in water and the changes in solubility of sodium chloride along with the temperature are not obvious, sodium chloride obtained by acidification of disodium iminodiacetate by hydrochloric acid is firstly separated, so that the content of sodium chloride is reduced, the precipitation of sodium chloride in the subsequent reaction is avoided, and the reaction yield is improved; meanwhile, the viscosity of raw materials is reduced, so that the mixing of the raw materials becomes more uniform. Secondary, as sodium chloride in the system is reduced, wastewater produced by washing during separation of N-(phosphonomethyl) iminodiacetic acid is reduced. Experimental results show that the yield of N-(phosphonomethyl) iminodiacetic acid prepared by the method provided by the invention can be up to above 93%.

Owner:CHONGQING UNISPLENDOUR CHEM

Complex flavouring with function of adding saltiness, adding freshness and containing less sodium

ActiveCN101243861BReduce sodium chloride contentSimplify cooking operationsFood shapingFood preparationCooking processLow sodium

The invention discloses a low-sodium functional compound seasoning which can increase the taste of salty and savory. The invention is characterized in that the low-sodium salt is the main raw material on the basis of which one or a plurality of functional nutrients that can increase the taste of savory and salty, and one or a plurality of savory materials are added; then after mixing, stirring, and granulating, the compound seasoning is made. The compound comprises 20 to 80 portions weight of low-sodium salt, 10 to 30 portions weight of functional nutrient and 3 to 15 portions weight of savory materials. Therefore, the compound seasoning has the advantages of effectively reducing the ingestion of NaCI, outstanding flavoring effect and nutrient function. What's more, the invention can be operated simply for the taste of salty, savory and delicious can be got at a time in the process of cooking.

Owner:上海东南清宫食品工业有限公司

Preparation method of novel nutrition low-sodium salt

ActiveCN105433345AReduce sodium chloride contentReduce contentFood ingredient as taste affecting agentFlavorFood grade

The invention discloses composition and a preparation method of a novel nutrition low-sodium salt. Food-grade sodium chloride, potassium chloride, disodium 5'-ribonucleotide, a seaweed delicious liquid and ammonium ferric citrate are dissolved and stirred and the mixture is subjected to ball milling so that the novel nutrition low-sodium salt is obtained. The novel nutrition low-sodium salt substantially reduces sodium content and contains a freshness improvement component extracted from plants. Through ball milling mixing, sodium chloride and potassium chloride are uniformly mixed so that the problem of uneven mixing caused by uneven particle sizes is avoided. The novel nutrition low-sodium salt keeps low sodium salt salinity, has a delicious taste, solves the problem of a potassium chloride bitter taste, has a good food local flavor and can prevent hypertension. The preparation method and preparation equipment can be operated simply and are suitable for industrial production.

Owner:CHINASALT JINTAN

Method for continuously synthesizing sodium dichloro isocyanurate dihydrate by wet process

ActiveCN102206192AIncrease productivityReduce energy consumptionOrganic chemistrySodium carbonateChemistry

The invention belongs to the technical field of disinfecting and sterilizing agent and discloses a method for continuously synthesizing sodium dichloro isocyanurate dihydrate by using cyanuric acid, caustic soda liquid and chlorine. The production method comprises the following steps: synthesizing disodium cyanurate, filtering, purifying, performing two stages of chlorination, cooling, crystallizing, centrifuging, mixing with sodium carbonate with a wet process, drying, granulating and the like to obtain the sodium dichloro isocyanurate dehydrate. The method is characterized in that: the adoption of a continuous chlorination synthesis process improves the utilization rate of equipment; and the process avoids dissolution, alkali addition and chlorine addition processes, so the production cost is reduced.

Owner:河北冀衡化学股份有限公司

Nutrition type pickles and production method

InactiveCN1795754AFull of nutritionGood fresh-keeping effectFood preparationPickled vegetablesNutrient

A method for preparing nutritive pickled vegetables containing the active components of Chinese medical stone includes such steps as spraying the powder of Chinese medical stone onto the plant used as raw material in its early and / or middle growth stage, spraying the hydrated liquid of Chinese medical stone onto said plant in its middle and / or later growth stage, adding Chinese medical stone in its pickling procedure. Its advantages are rich nutrients and high effect to remove harmful heavy metal elements (Hg, Pb, Cr, etc).

Owner:季庆云 +1

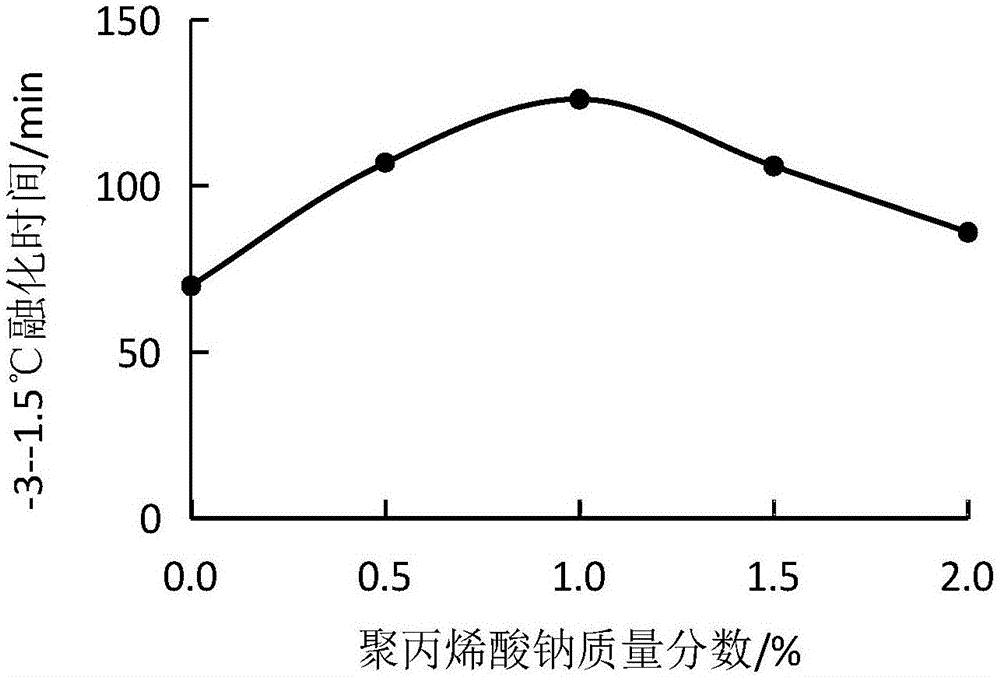

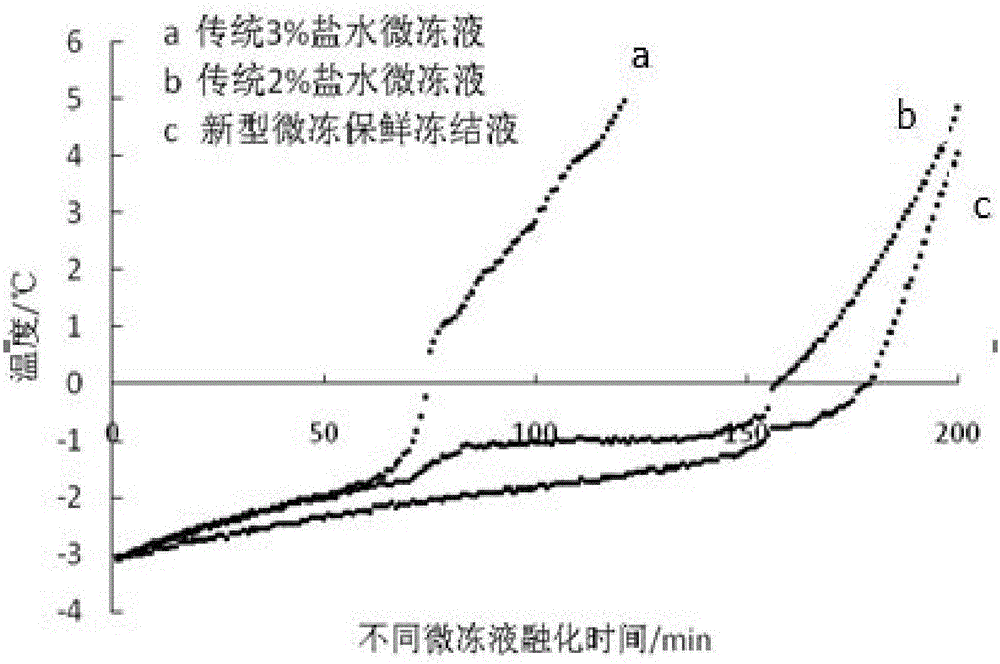

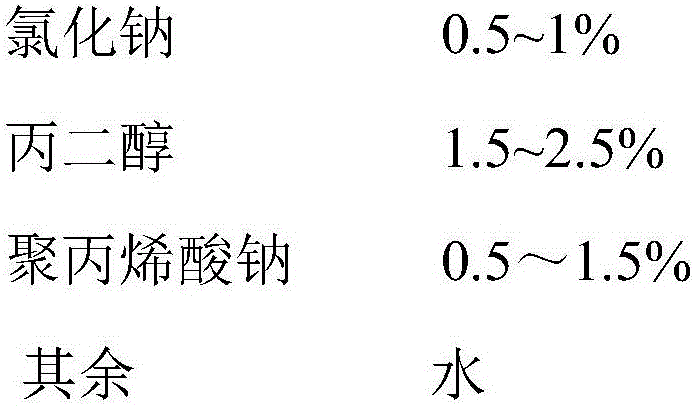

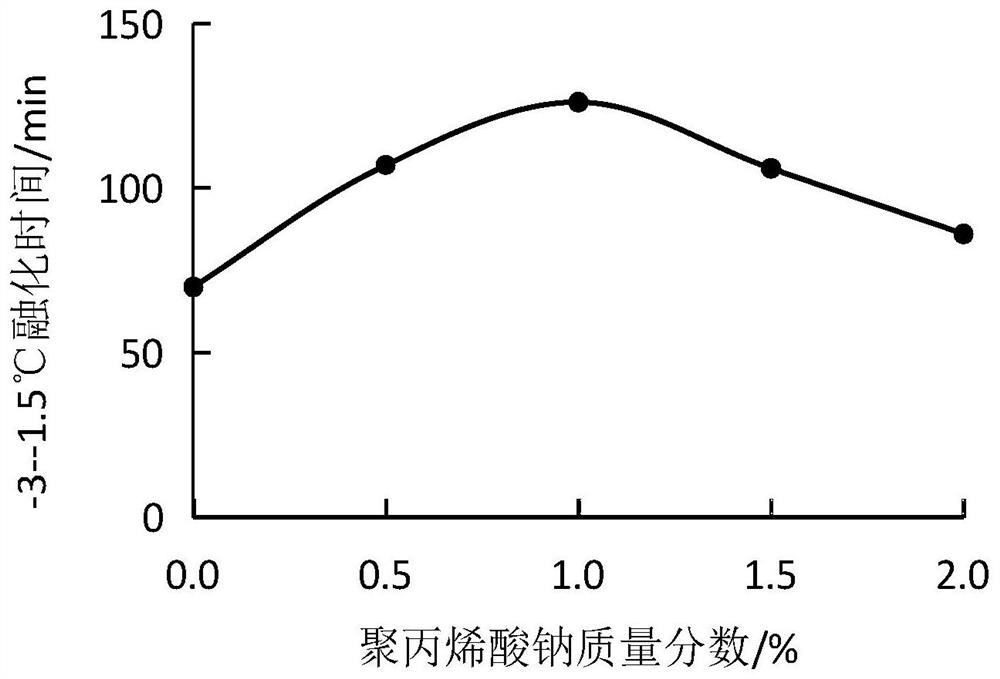

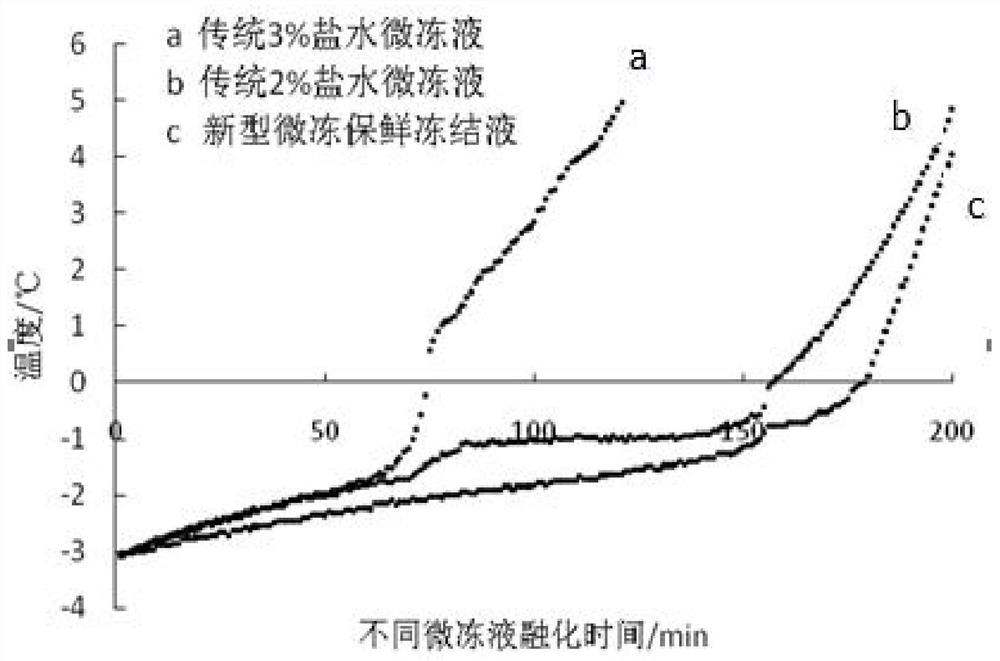

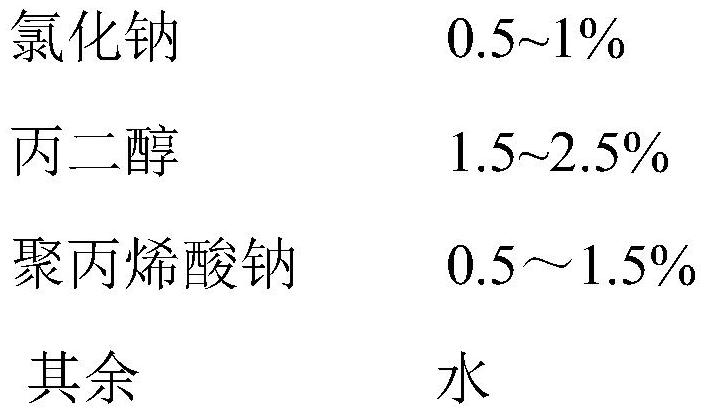

Ice for food partial freezing fresh keeping

ActiveCN106665791AReduce meltingSolve the problem of using security and application stabilityMeat/fish preservation by freezing/coolingCold chainAdditive ingredient

The invention discloses ice for food partial freezing fresh keeping. The ice mainly comprises the following ingredients in percentage by mass: 0.5 to 1 percent of sodium chloride, 1.5 to 2.5 percent of propanediol, 0.5 to 1.5 percent of sodium polyacrylate and the balance water. In the preparation process, sodium polyacrylate is firstly dissolved by propanediol; then, the solution is mixed with sodium chloride and water to prepare a mixed solution; next, the mixed solution is made into ice. The fresh keeping ice point range is -3 to -1.5 DEG C, and is lower than the ice point temperature of 0 DEG C of conventional ice; the maintaining time is obviously superior to that of the partial freezing ice prepared from NaCl; the recipe ingredient is harmless to the human body health; the ice point temperature is reduced through combining the sodium chloride and the propanediol for the first time; the sodium polyacrylate is used for prolonging the ice thawing time. The ice provided by the invention solves the problems that in the cold chain logistics, the ice point temperature of the ordinary ice is high; the thawing time is short; the long-distance cold chain transportation is not facilitated. The ice temperature storage environment can be created for the food in the long-distance cold chain transportation process; the transportation process temperature stability is maintained.

Owner:SOUTH CHINA SEA FISHERIES RES INST CHINESE ACAD OF FISHERY SCI

Preparation method capable of improving yield of medium-molecular-weight hydroxyethyl starch

The invention discloses a preparation method capable of improving yield of medium-molecular-weight hydroxyethyl starch, and belongs to the technical field of amylopectin chemical derivatives. The method includes the steps: firstly, adding amylopectin and hydrochloric acid into water and heating for hydrolyzing; secondly, adding etherifying agent and preserving heat for reaction; thirdly, adjusting pH (potential of hydrogen) value of reaction solution to range from 5 to 7, decoloring, leaching and filtering; fourthly, ultrafiltering and then electrodialyzing; and fifthly, nano-filtrating for concentration and spray-drying to obtain medium-molecular-weight hydroxyethyl starch. By means of the membrane refining process which combines ultrafiltration and electrodialysis, ultrafiltration times are greatly reduced, the refining process is shortened, and product yield and quality are improved. Further, by means of the process of nano-filtrating for concentration before spray-drying, spray-drying efficiency can be improved while yield of the hydroxyethyl starch can be improved. Additionally, products made by the method are low in sodium chloride and stable and reliable in quality; and since water is used as a dispersion medium, production safety is realized, and pollution is avoided.

Owner:HEBEI GUOLONG PHARMA CO LTD

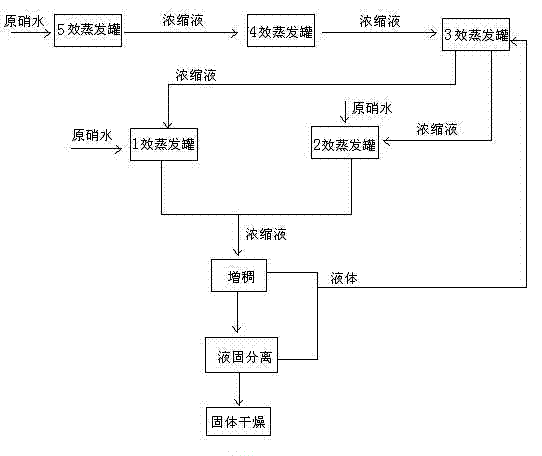

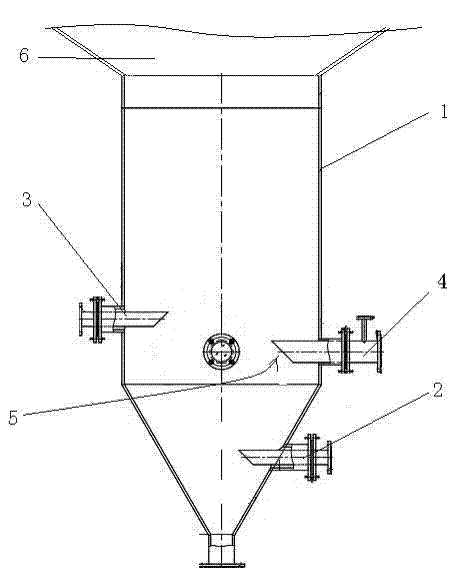

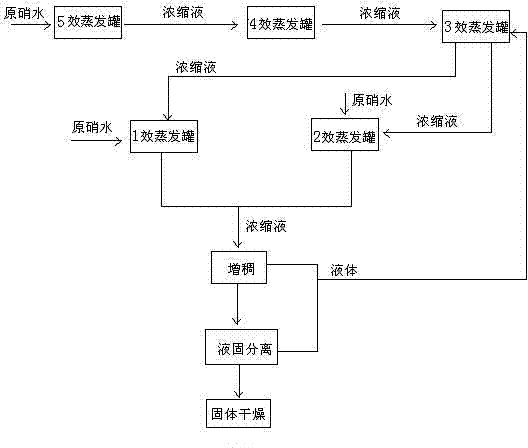

Sodium sulphate preparation method and sodium sulphate foot structure of evaporator therefor

InactiveCN102502713ADilution concentrationReduce the temperatureAlkali metal sulfites/sulfatesSingle effectLow sodium

The invention discloses a sodium sulphate preparation method and a sodium sulphate foot structure of an evaporator for the sodium sulphate preparation method. The method comprises the following steps of: (1) sequentially evaporating sodium sulphate liquid at least by a five-effect evaporator, a four-effect evaporator and a triple-effect evaporator, then evaporating the concentrated solution in the triple-effect evaporator in a double-effect evaporator and a single-effect evaporator separately, wherein a sodium sulphate liquid inlet is arranged at the middle lower part of the sodium sulphate foot of each of the double-effect evaporator and the single-effect evaporator, then introducing low sodium chloride raw-material sodium sulphate liquid from the inlets so as to decrease the temperature of the concentrated solution at the discharge port of the sodium sulphate foot in the evaporator to 70-80DEG C, and decrease the content of sodium chloride to 140-180 g / L; and (2) pumping the concentrated solution of temperature 70-80DEG C and sodium chloride content 140-180 g / L obtained in the step (1) into a thickening apparatus for thickening, separating the liquid from solid, feeding the obtained solid into a drying apparatus for drying, and pumping the mother solution of the thickening and drying processes into the triple-effect evaporator for recycling.

Owner:江苏白玫化工有限公司

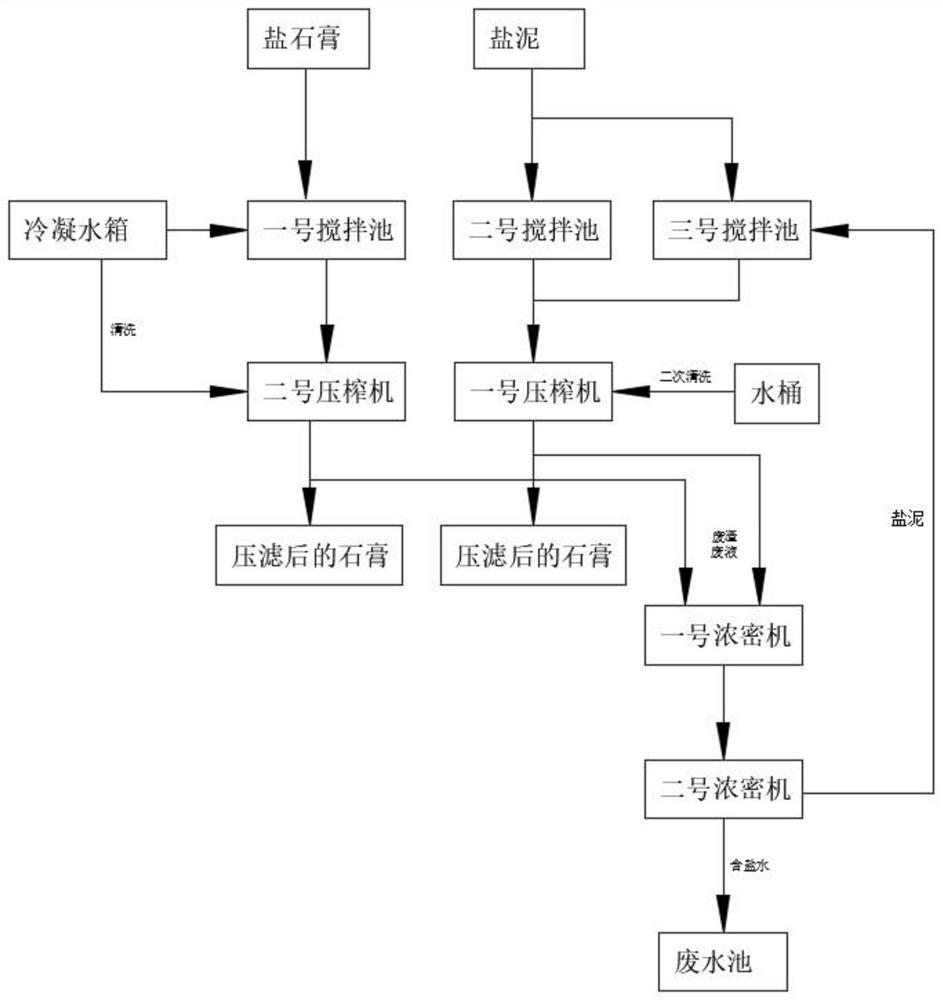

Salt gypsum and salty mud solid waste harmless treatment process

PendingCN113461043AReduce sodium chloride contentIncrease incomeSolid waste disposalCalcium/strontium/barium sulfatesPhysical chemistryEnvironmental engineering

The invention discloses a salt gypsum and salty mud solid waste harmless treatment process, and belongs to the technical field of salt gypsum treatment. The process can systematically treat salt gypsum and salty mud generated by a salt factory, the salt content (calculated according to the content of Cl<->) in the raw material salt gypsum is reduced to 1.0% or below and the water content is about 25% through the steps of water adding, stirring, squeezing, water removing and the like, the influence on the environment is reduced to the greatest extent, the sodium chloride content in the salt gypsum is greatly reduced, the gypsum generated after treatment can be reasonably used, and the gypsum and brine generated in the process of treating the salt gypsum and the salty mud increase the income of factories and improve the enthusiasm of treating the salt gypsum and the salty mud.

Owner:中国平煤神马集团联合盐化有限公司

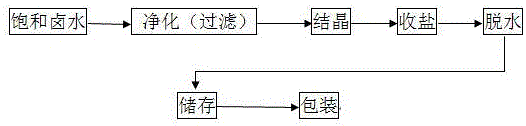

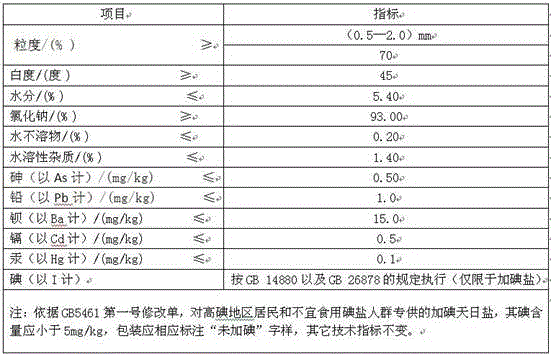

Preparation technology of solar salt

InactiveCN106185990ASimple processGood process parametersAlkali metal chloridesAtmospheric dustFiltration

The invention relates to a preparation technology of salt, in particular to a preparation technology of solar salt. The preparation technology of the solar salt comprises the specific steps of 1, making saturated brine from seawater, and transporting the saturated brine to a purifying pond through a pipeline for filtration and purification so as to filter off biological dead bodies, plant residual bodies, atmospheric dust fall and the like in the saturated brine; 2, adding the purified pure brine into a crystallization pond, controlling the depth of water in the crystallization pond to be 5-10cm, and during sun-curing, performing salt spinning and brine spinning with a rotary rake; 3, when the sodium-magnesium ratio of the brine is smaller than or equal to 2, stopping crystallization; 4, when the particles of the salt reach to 0.5-2.0mm and the evaporation amount of the salt reaches to 7mm, collecting the salt, when the salt needs to be collected, gathering the salt into heaps through cleaning tools, washing the salt with cleaning brine, then performing vacuum suction filtration and dehalogenation on the salt, and when the water content of the salt is smaller than or equal to 5.4%, stopping the operations of vacuum suction filtration and dehalogenation; and 5, preserving the obtained solar salt, packaging the preserved solar salt, and enabling the packaged solar salt to appear on the market.

Owner:DALIAN YANHUA GROUP

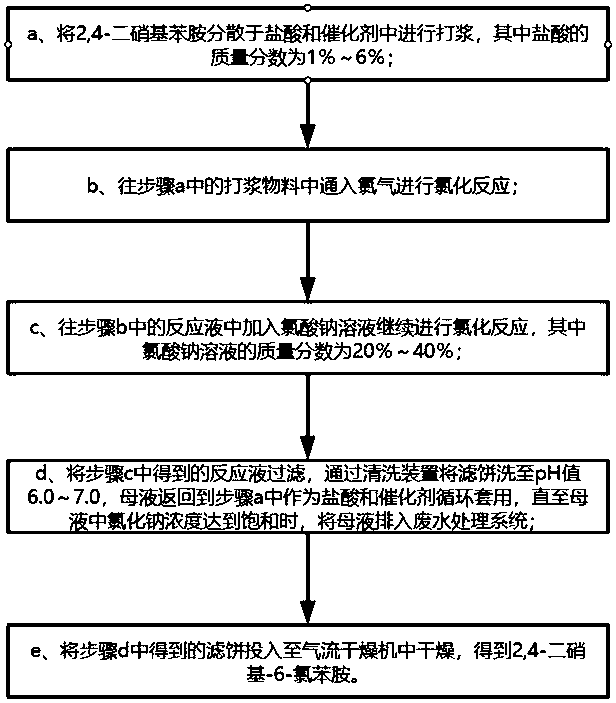

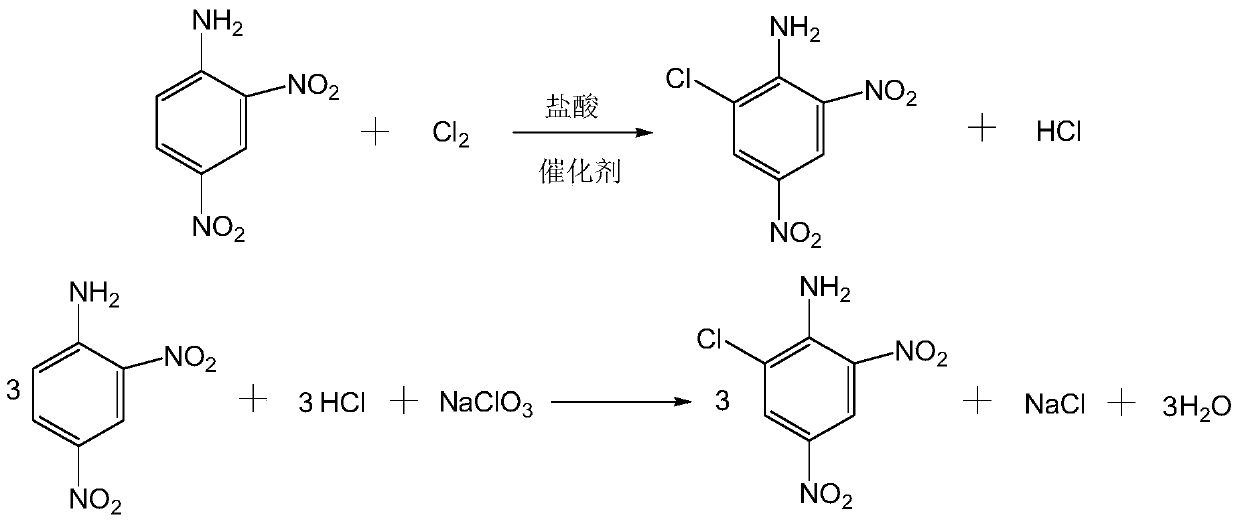

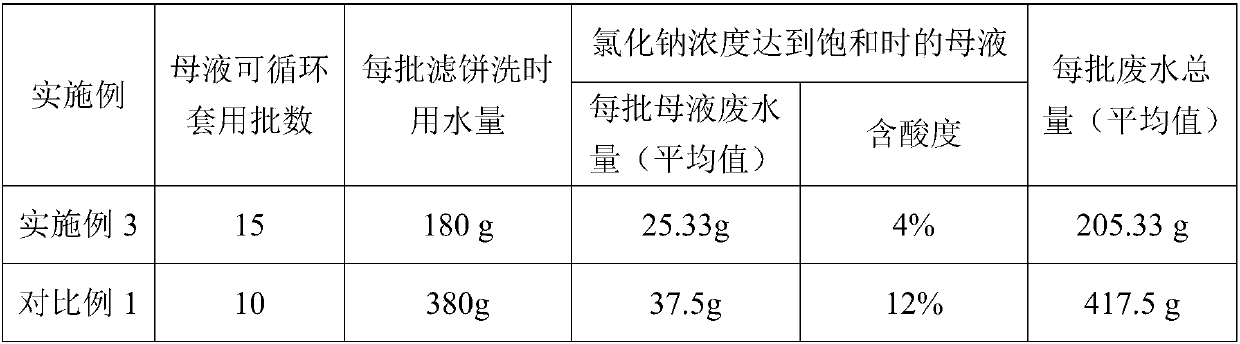

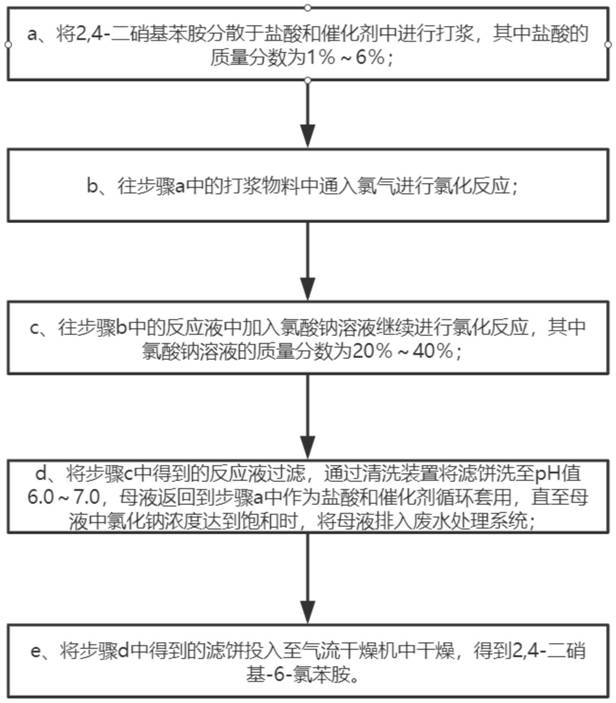

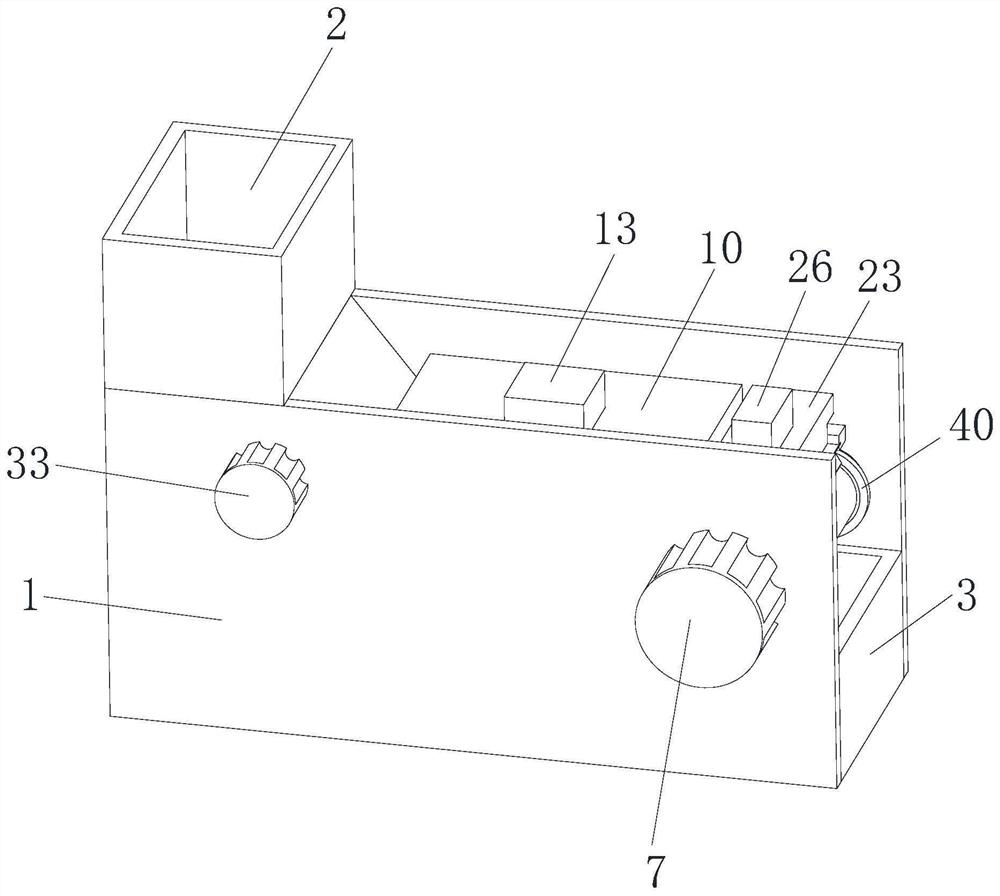

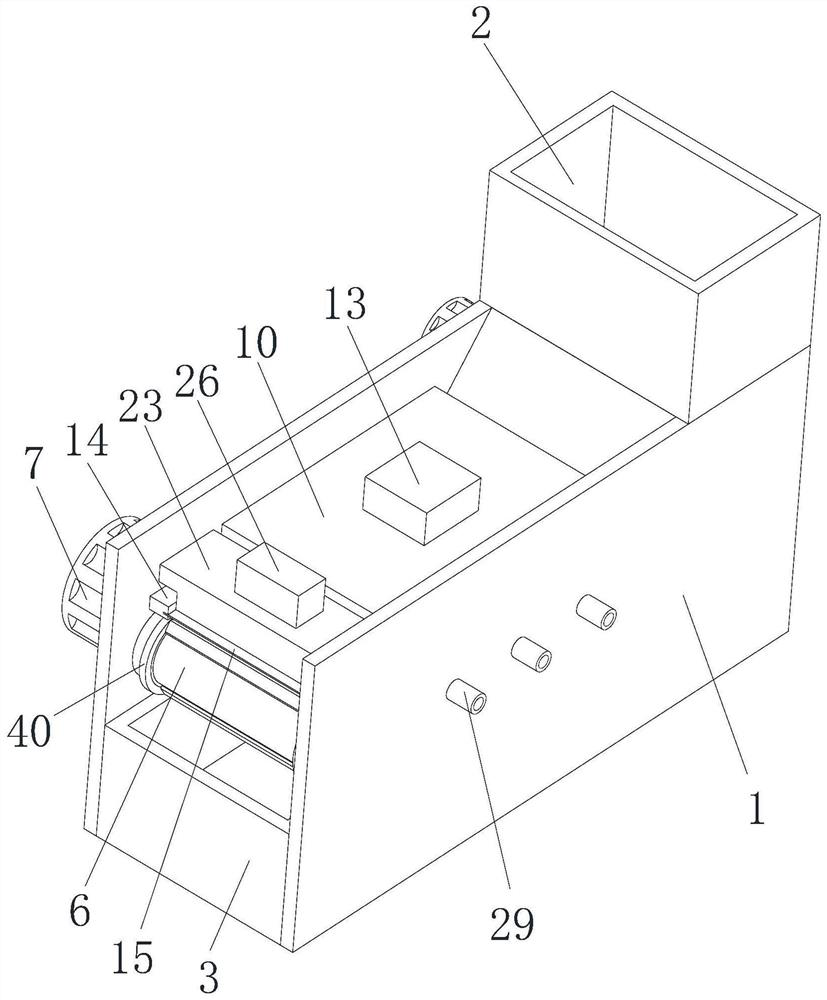

Preparation method of 6-chloro-2,4-dinitroaniline

ActiveCN110698348AEmission reductionPrevent splashAmino compound purification/separationOrganic compound preparationPtru catalystWater chlorination

The invention discloses a preparation method of 6-chloro-2, 4-dinitroaniline. The preparation method comprises the following steps: a, dispersing 2,4-dinitroaniline in hydrochloric acid and a catalyst, and carrying out pulping, wherein the mass fraction of the hydrochloric acid is 1-6 wt%; b, introducing chlorine gas into a pulping material obtained in the step a and carrying out a chlorination reaction; c, adding a sodium chlorate solution into a reaction solution obtained in the step b, and continuing the chlorination reaction, wherein the mass fraction of the sodium chlorate solution is 20%-40%; d, filtering a reaction liquid obtained in the step c, washing a filter cake by a washing device until the pH value of the filter cake is 6.0-7.0, returning mother liquor to the step a to be circularly and indiscriminately used as hydrochloric acid and the catalyst, and discharging the mother liquor into a wastewater treatment system until the concentration of sodium chloride in the mother liquor is saturated; and e, putting the filter cake obtained in the step d into an air flow drying machine for drying to obtain the 2,4-dinitro-6-chloroaniline. The method has the advantages of small overall water consumption and good cleaning effect.

Owner:浙江汇翔新材料科技股份有限公司

Nanometer ferroferric oxide pigment composition and production method thereof

InactiveCN109627806AUniform particlesNo agglomerationPigment physical treatmentPigment treatment with non-polymer organic compoundsOrganic acidOil phase

The invention relates to the technical field of pigments, in particular to a nanometer ferroferric oxide pigment composition and a production method thereof. Under the action of an externally appliedmagnetic field, FeCl2 is dissolved in water and stirred under the alkaline condition, air is introduced, Fe2<+> is oxidized into ferroferric oxide, and the pH value is adjusted to the acidity; then organic acid salt is added, after stirring is carried out, organic acid is added, the ferroferric oxide enters an oil phase, and the oil phase is separated out, that is, a ferroferric oxide compositionproduct. The nanometer ferroferric oxide pigment composition and the production method thereof have the advantages that the produced nanometer ferroferric oxide crystal form is in a cube shape, particles are uniform, no agglomeration phenomenon appears, and the nanometer ferroferric oxide pigment composition can be applied to a transparent system; the production energy consumption is low, and thestability of the product is high.

Owner:赤峰盛森硅业科技发展有限公司

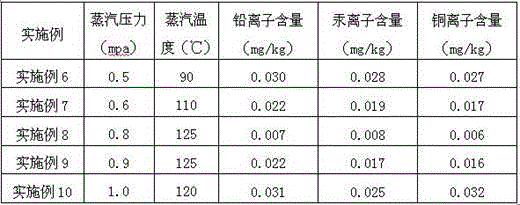

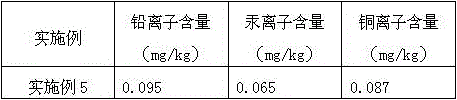

Plant salt containing sea salt and method for preparing plant salt through process of removing heavy metal ions through extended aeration method

InactiveCN105852032ASalt low in sodium chlorideReduce sodium chloride contentFood scienceFiltrationPhysical chemistry

The invention provides plant salt containing sea salt. The plant salt is characterized in that the plant salt contains sea salt, the content of NaCl is 78-82%, the content of lead ions is smaller than or equal to 0.03 mg / kg, the content of mercury ions is smaller than or equal to 0.05 mg / kg, and the content of copper ions is smaller than or equal to 0.05 mg / kg. The invention further provides a method for preparing the plant salt through the process of removing heavy metal ions through an extended aeration method. The method is characterized by including the step of preparing refined bittern, wherein filtering is conducted and includes mechanical filtration and nanofiltration, nanofiltration temperature is 20-25 DEG C, and pressure is controlled to be 0.2-1.2 MPa. In the implementation process, the filtering process is advanced, the service life of a nanofiltration membrane is prolonged, the nanofiltration membrane is now replaced after being used 8-10 times instead of existing 2-5 times, and filtration production cost is greatly saved.

Owner:王胜

A kind of synthetic technique of 2,4-dinitro-6-chloroaniline

ActiveCN105367428BReduce acid contentReduce sodium chloride contentOrganic compound preparationAmino compound preparationSodium chlorateWastewater

A synthetic technology for 2-chloro-4,6-dinitroaniline is disclosed. The technology comprises (1) dispersing 2,4-dinitroaniline in hydrochloric acid and a catalyst and stirring to form a slurry, wherein the mass fraction of hydrochloric acid is 1-8%; (2) introducing chlorine into the slurry obtained in the step (1) for chlorination reaction; (3) adding a sodium chlorate solution into the reaction solution in the step (2) and continuing performing chlorination reaction, wherein the mass fraction of the sodium chlorate solution is 20%-40%; and (4) filtering the reaction solution obtained in the step (3), washing the filter cake until the pH value is 6.0-7.0, returning the mother liquid to the step (1) as hydrochloric acid and the catalyst for cyclic utilization utile the sodium chloride in the mother liquid is saturated, and discharging the mother liquid into a wastewater processing system, wherein the molar ratio of 2,4-dinitroaniline, chlorine and sodium chlorate is 1:(0.2-0.8):(0.06-0.3). The technology is high in yield, the purity of the obtained product is high, cost is low, the cycling times of the mother liquid are more, the wastewater discharging amount is less, and the benifit of energy saving and emission reduction is substantial.

Owner:ZHEJIANG LONGSHENG GROUP +1

A kind of preparation method of 6-chloro-2,4-dinitroaniline

ActiveCN110698348BEmission reductionPrevent splashAmino compound purification/separationOrganic compound preparationPtru catalystWater chlorination

Owner:浙江汇翔新材料科技股份有限公司

A kind of ice for slightly freezing food

ActiveCN106665791BReduce meltingDelay ice meltingMeat/fish preservation by freezing/coolingCold chainThermodynamics

The invention discloses ice for food partial freezing fresh keeping. The ice mainly comprises the following ingredients in percentage by mass: 0.5 to 1 percent of sodium chloride, 1.5 to 2.5 percent of propanediol, 0.5 to 1.5 percent of sodium polyacrylate and the balance water. In the preparation process, sodium polyacrylate is firstly dissolved by propanediol; then, the solution is mixed with sodium chloride and water to prepare a mixed solution; next, the mixed solution is made into ice. The fresh keeping ice point range is -3 to -1.5 DEG C, and is lower than the ice point temperature of 0 DEG C of conventional ice; the maintaining time is obviously superior to that of the partial freezing ice prepared from NaCl; the recipe ingredient is harmless to the human body health; the ice point temperature is reduced through combining the sodium chloride and the propanediol for the first time; the sodium polyacrylate is used for prolonging the ice thawing time. The ice provided by the invention solves the problems that in the cold chain logistics, the ice point temperature of the ordinary ice is high; the thawing time is short; the long-distance cold chain transportation is not facilitated. The ice temperature storage environment can be created for the food in the long-distance cold chain transportation process; the transportation process temperature stability is maintained.

Owner:SOUTH CHINA SEA FISHERIES RES INST CHINESE ACAD OF FISHERY SCI

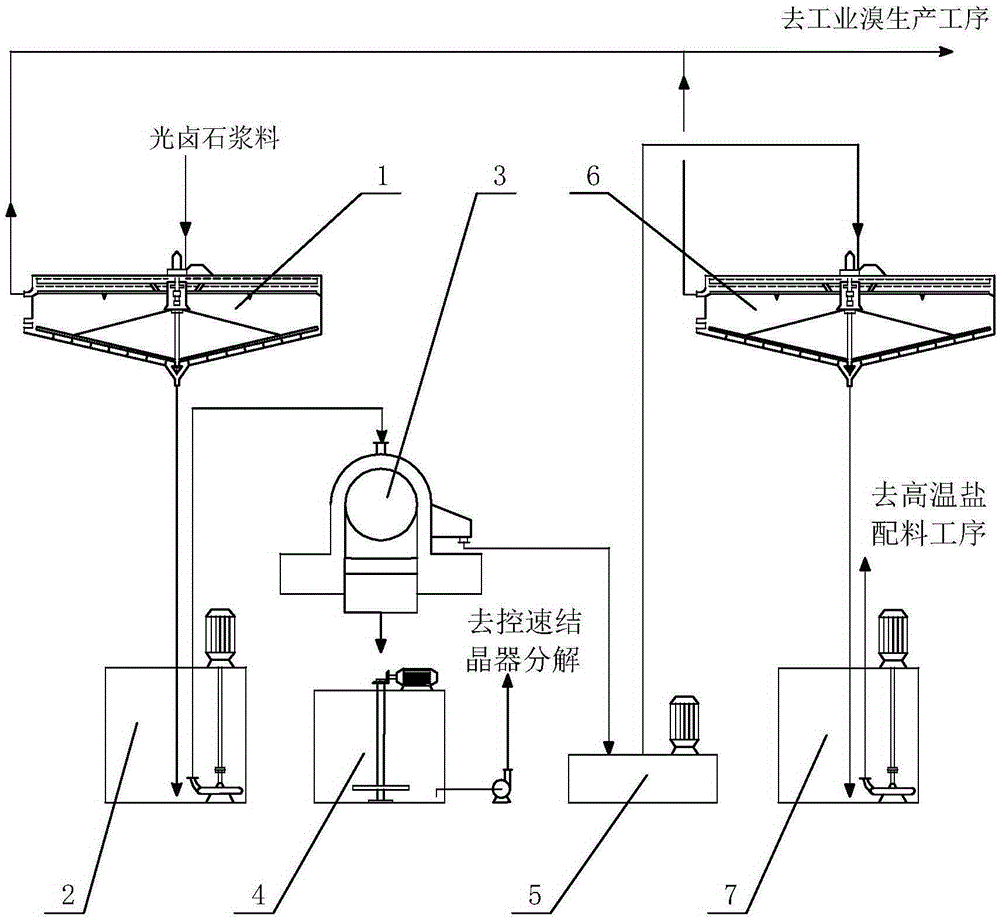

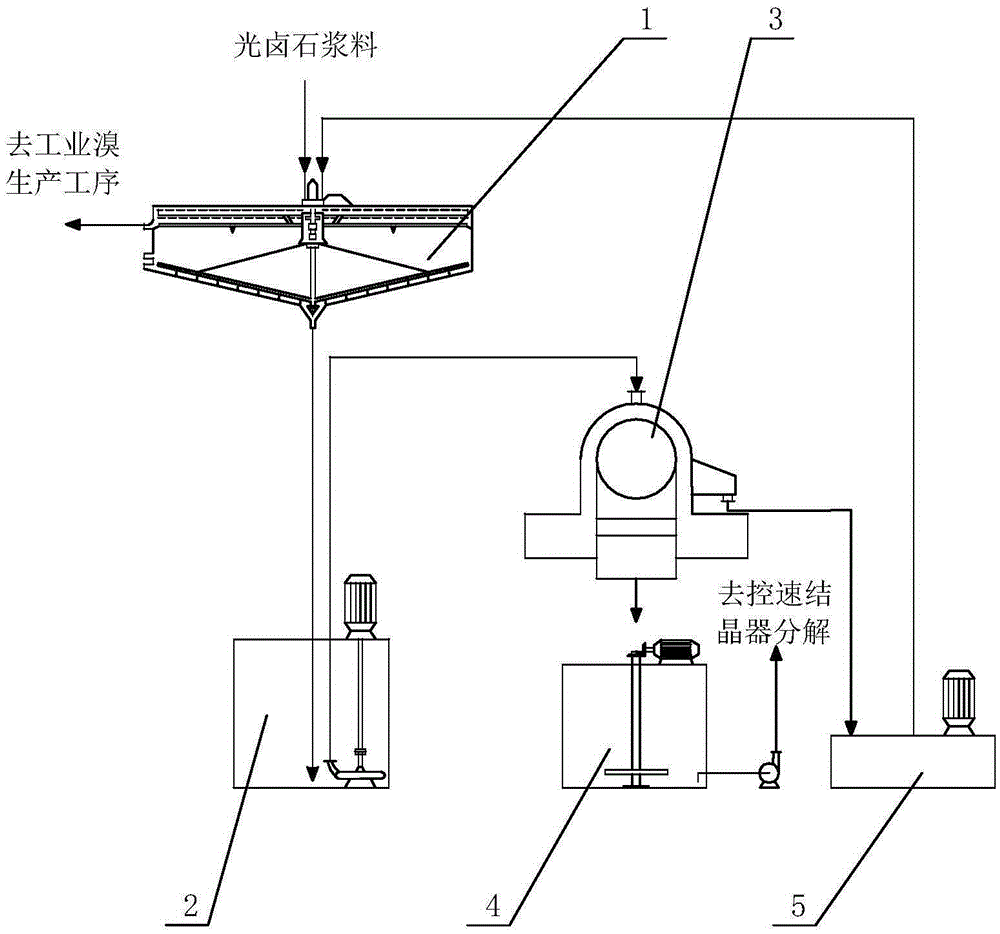

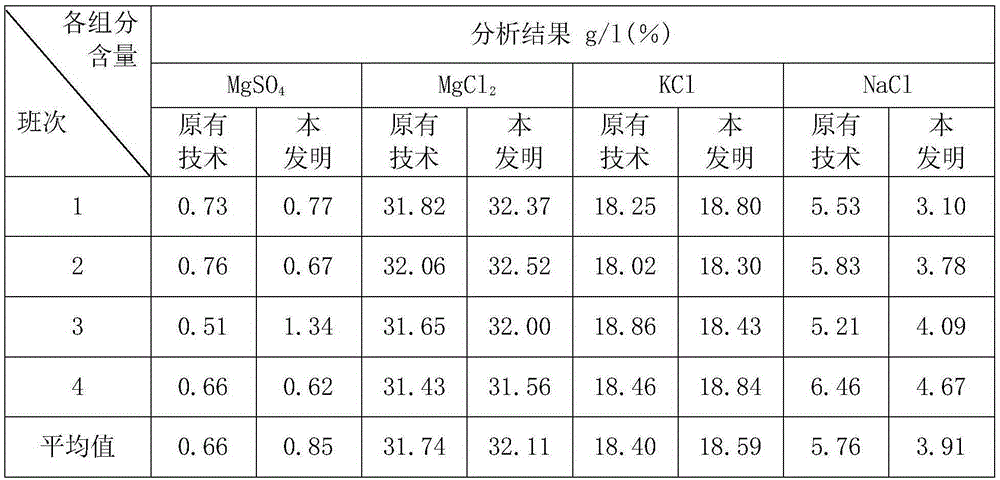

A kind of recovery and utilization method of carnallite liquid in the production of potassium chloride

InactiveCN104261431BQuality improvementImprove washing rateMagnesium sulfatesBromine/hydrogen-bromideBromineLiquid tank

The invention discloses a recycling method for a carnallite post-throwing liquid in production of potassium chloride. The recycling method comprises the following steps: after separating carnallite which is settled by a carnalite settler by a centrifugal machine, washing the solid in a trough and conveying the solid to a speed control crystallizer; buffering the post-throwing liquid by virtue of a post-throwing liquid tank, conveying the post-throwing liquid to a post-throwing liquid settler and conveying a salt slurry which is settled by the post-throwing liquid settler to a high-temperature salt dosing step for production of industrial refined salt and magnesium sulfate monohydrate; and conveying an overflowing liquid in the upper layer by using the post-throwing liquid settler and the carnalite settler to an industrial bromine production step for production of industrial bromine. According to the method disclosed by the invention, the quality of a carnallite product in production of potassium chloride is improved, so that the content of potassium chloride in the carnallite product is reduced, the water consumption in a decomposing and washing step is reduced, the washing yield of potassium chloride is improved, the loss of potassium chloride in the washing process is avoided, and meanwhile, the potassium chloride product is improved, so that the targets of improving the quality and reducing the consumption are achieved.

Owner:天津长芦汉沽盐场有限责任公司

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com