Patents

Literature

71results about How to "Good nutrition and health function" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Complex flavouring with function of adding saltiness, adding freshness and containing less sodium

ActiveCN101243861AReduce sodium chloride contentSimplify cooking operationsFood shapingFood preparationCooking processLow sodium

The invention discloses a low-sodium functional compound seasoning which can increase the taste of salty and savory. The invention is characterized in that the low-sodium salt is the main raw material on the basis of which one or a plurality of functional nutrients that can increase the taste of savory and salty, and one or a plurality of savory materials are added; then after mixing, stirring, and granulating, the compound seasoning is made. The compound comprises 20 to 80 portions weight of low-sodium salt, 10 to 30 portions weight of functional nutrient and 3 to 15 portions weight of savory materials. Therefore, the compound seasoning has the advantages of effectively reducing the ingestion of NaCI, outstanding flavoring effect and nutrient function. What's more, the invention can be operated simply for the taste of salty, savory and delicious can be got at a time in the process of cooking.

Owner:上海东南清宫食品工业有限公司

Corn oligopeptide powder buccal tablet and preparation method thereof

ActiveCN103005440ASlows the rate at which ethanol is absorbedAvoid damageFood preparationFood additiveAlcoholisms

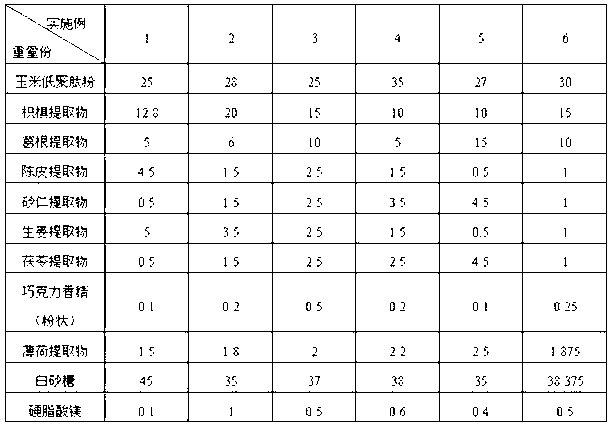

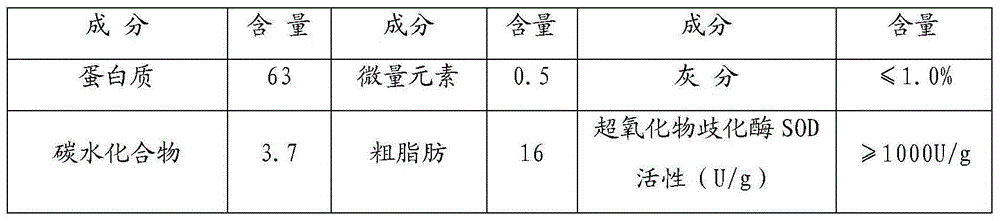

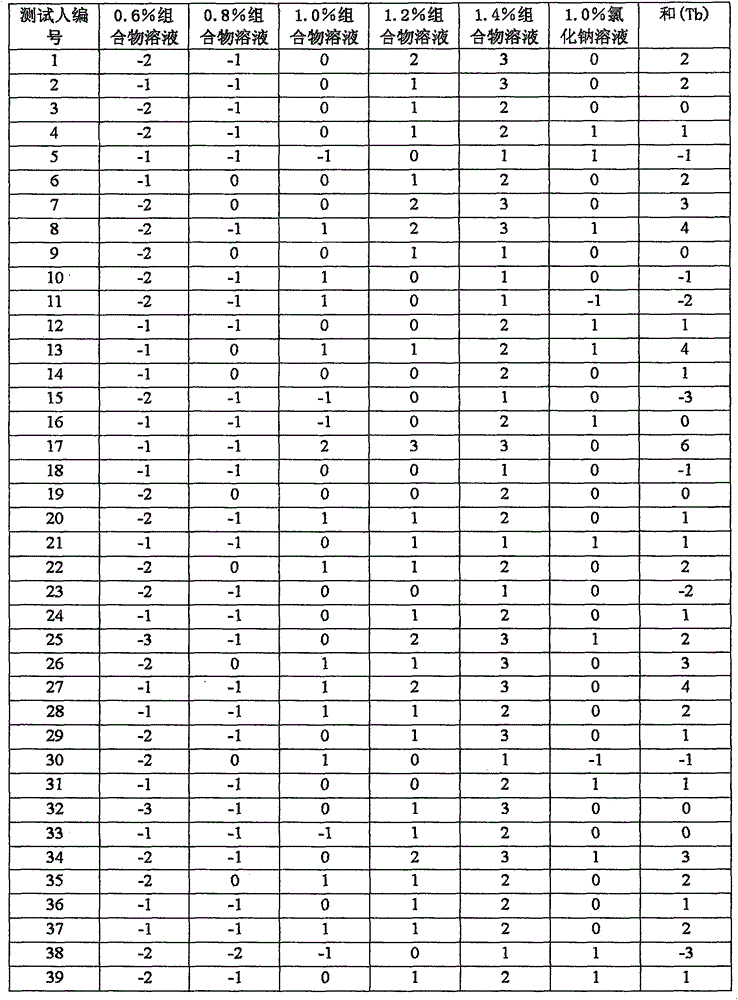

The invention discloses a corn oligopeptide powder buccal tablet and a preparation method thereof. The corn oligopeptide powder buccal tablet comprises the following components in part by weight: 25-3-5 parts of corn oligopeptide powder, 10-20 parts of hovenia acerba extract, 5-1-5 parts of kudzu root extract, 0.5-5 parts of dried tangerine peel extract, 0.5-5 parts of amomum extract, 0.5-5 parts of ginger extract, 0.5-5 parts of poria extract, 0.1-0.-5 parts of food additive, 1.5-2.-5 parts of mint extract, 35-4-5 parts of white granulated sugar and 0.1-1 part of anti-caking agent. The preparation method comprises the following steps: crushing raw materials, softening the raw materials, granulating by a wet method, drying, sieving, finishing granules, adding the anti-caking agent, tabletting and packaging. The corn oligopeptide powder buccal tablet is scientific and reasonable in formulation, all-around in nutritional and health-care functions of protecting the liver, relieving alcoholism, strengthening the spleen and the stomach and reducing the blood pressure and the blood lipid, good in palatability, safe and non-toxic; and the preparation method is simple and feasible and low in cost.

Owner:江苏青贝健康科技有限公司

Preparation method of wild pawpaw fruit wine

InactiveCN101928657ARetain nutritional valueShorten the production cycleAlcoholic beverage preparationMicroorganism based processesFruit wineIndustrial fermentation

This invention discloses a preparation method of a wild pawpaw fruit wine. The method comprises the following steps of: after treating rice pulp with a liquefying enzyme and a saccharifying enzyme, mixing the treated rice pulp and wild pawpaw juice according to a proportion of 1:1-1.5(W / W) and fermenting the mixture to obtain the wild pawpaw fruit wine. Compared with the prior art, the preparation method of the invention simplifies the production process, shortens the production period, reduces the production cost, improves the economic benefit and contributes to the industrial fermentation mass production of the wild pawpaw fruit wine. The wild pawpaw fruit wine prepared by the method is mellow, has the faint scent of wild pawpaw, is amber and transparent in colour, offers a pure mouthfeel and long lingering aftertaste, better retains the nutritional value and special flavor of the wild pawpaw and also has better nutritional and healthy functions of fruit wines.

Owner:贵阳南瓜蔬蔬科技有限公司

Seedlessness roxburgh rose and angelica keiskei compound drink and preparation method thereof

The invention provides a seedlessness roxburgh rose and angelica keiskei compound fruit and vegetable juice drink which is prepared from the following components in parts by weight: 20-80 parts of seedlessness roxburgh rose, 10-80 parts of angelica keiskei, 0-10 parts of stevia rebaudiana, 1-5 parts of citric acid, 0.5-3 parts of newtol, 0.1-0.2 parts of sodium carboxymethylcellulose, 0.01-0.03 parts of xanthan gum, 0.01-0.03 parts of sodium copper chlorophyllin and defined quantity of water. The invention further comprises a preparation method of the seedlessness roxburgh rose and angelica keiskei compound drink, and the preparation method comprises processes of clear juice preparation, mixing, homogenizing, degassing, sterilizing and the like. Prepared seedlessness roxburgh rose and angelica keiskei compound fruit is rich in bioactive constituents such as chalcone, superoxide dismutase (SOD), natural organic germanium, choline, a plurality of families of vitamins, in particualr B12, pantothenic acid, vitamin C and the like and has abundant nutrition and health care effects. Simultaneously, products are good in taste and tasty in sour and sweet degree.

Owner:SHANGHAI JIAO TONG UNIV

Coix seed barley buckwheat coarse cereal noodle and production method thereof

InactiveCN104323129AChange rheological propertiesOvercome the monotonous tasteFood preparationBiotechnologyPolygonum fagopyrum

The invention discloses a coix seed barley buckwheat coarse cereal noodle and a production method thereof. According to the invention, wheat flour, coix seed flour, barley flour, buckwheat flour, wheat gluten, eggs and other raw materials are selected to prepare the coarse cereal noodle with the nutrition and health care efficacy of coix seed, barley and buckwheat, good taste, and reasonable nutrition collocation. The noodle product has slight red color, is smooth and delicate, has good molding properties, is chewy and elastic, and has a breaking rate of less than 5%, a hint of coarse cereal flavor, and good palatability. The noodle provided by the invention has the advantages that: 1. the coix seed, barley, buckwheat and other coarse cereals are selected to overcome the disadvantages of single taste and low nutritional value in traditional noodles, and the product has the characteristics of reasonable diet, and good nutrition and health care functions; 2. the wheat gluten is added to the product raw materials to change the noodle rheological properties, improve the water absorption of stock, shorten the curing time and reduce the breaking rate, so that the noodle can be delicate, chewy, rich in nutrition, and has the health care functions.

Owner:QINGDAO JIARUI BIOLOGICAL TECH

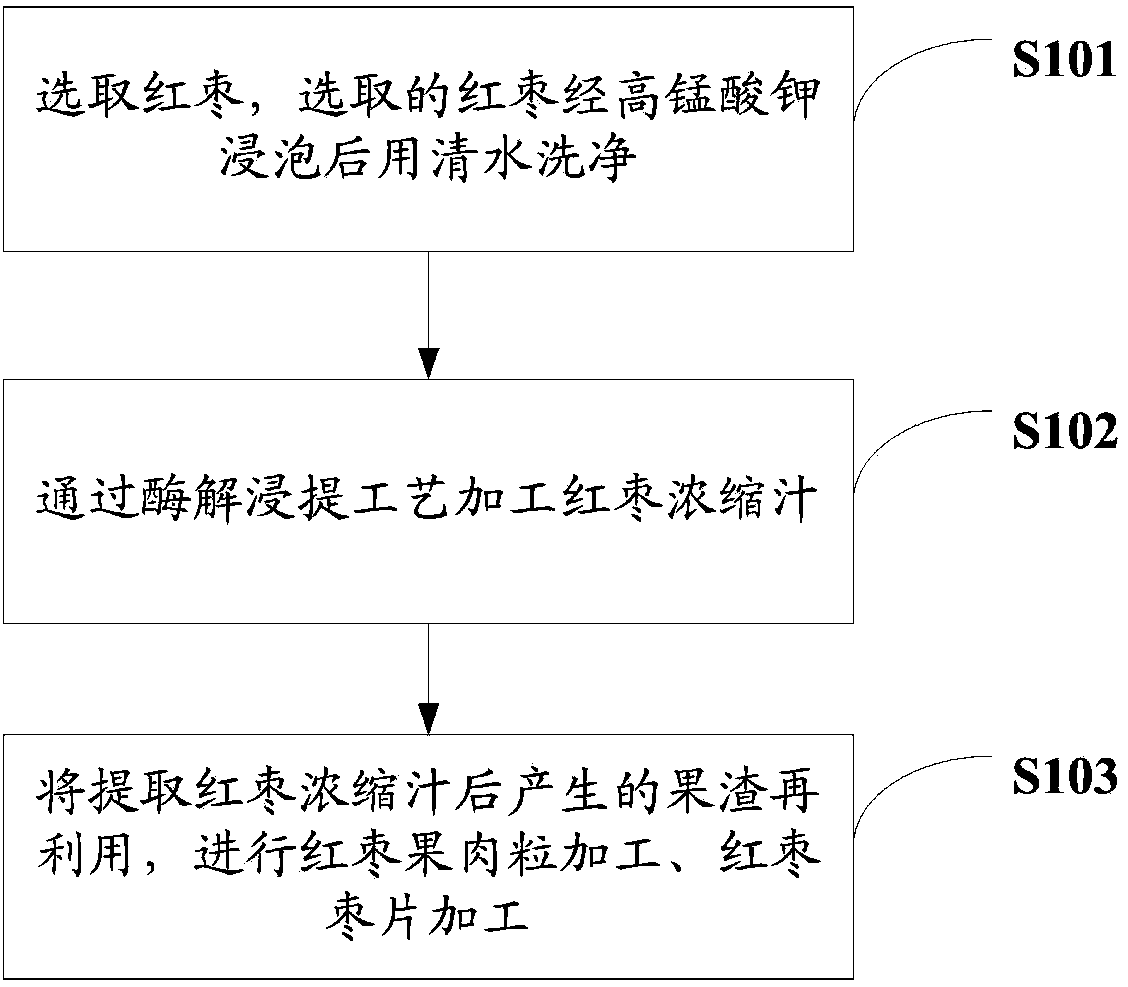

Process of comprehensively utilizing and processing red dates

The invention discloses a method of comprehensively processing and utilizing red dates. The method of comprehensively processing and utilizing red dates comprises the following specific steps: a step I of selecting red dates, soaking the selected red dates in potassium permanganate, and cleaning with clean water; a step II of processing red date concentrated juice by virtue of an enzymolysis leaching process; and a step III of recycling fruit residues generated by extracting the red data concentrated juice for processing of fruit grains of the red dates, and processing of red date pieces. According to the invention, the needs of consumers in different regions and different crowds can be satisfied, flavor is various, nutrition healthcare function is good, variety of date products is enriched, and economic benefits and social benefits are good.

Owner:XINJIANG GUANNONG FRUIT & ANTLER GROUP

Functional composition capable of dissolving rapidly, enhancing salty taste and reducing sodium content, and condiment

InactiveCN105166830AReduce sodium chloride contentGood health effectFood ingredient as anti-caking agentFood ingredient as foaming agentSolubilityOrganic acid

The invention discloses a salt substituting composition with good solubility and capable of enhancing the salty taste and reducing a sodium content, and a condiment. The functional composition disclosed by the invention mainly consists of table salt (NaCl), potassium chloride, organic acid and an alkaline foaming agent; on the basis of the composition, one kind or several kinds of flavoring substances are added, an appropriate quantity of additives and an appropriate quantity of filling agents are added, the composition, the flavoring substances, the additives and the filling agents are mixed and stirred to form a mixture, and the mixture is pelletized or tableted to obtain the corresponding condiment. The organic acid and the alkaline foaming agent react to generate gas, nutrient functional substances and water, by a method of controlling the kinds and the proportions of different organic acids and the alkaline foaming agents, different effects of natural granulation, salty taste enhancement, rapid dissolution, tabletting and functional nutrients introduction through products are achieved, and helping crowds to effectively reduce the absorption of sodium salt is facilitated. The invention provides the salt substituting composition and the condiment which are convenient to use and have obvious nutrient health care functions.

Owner:张震言

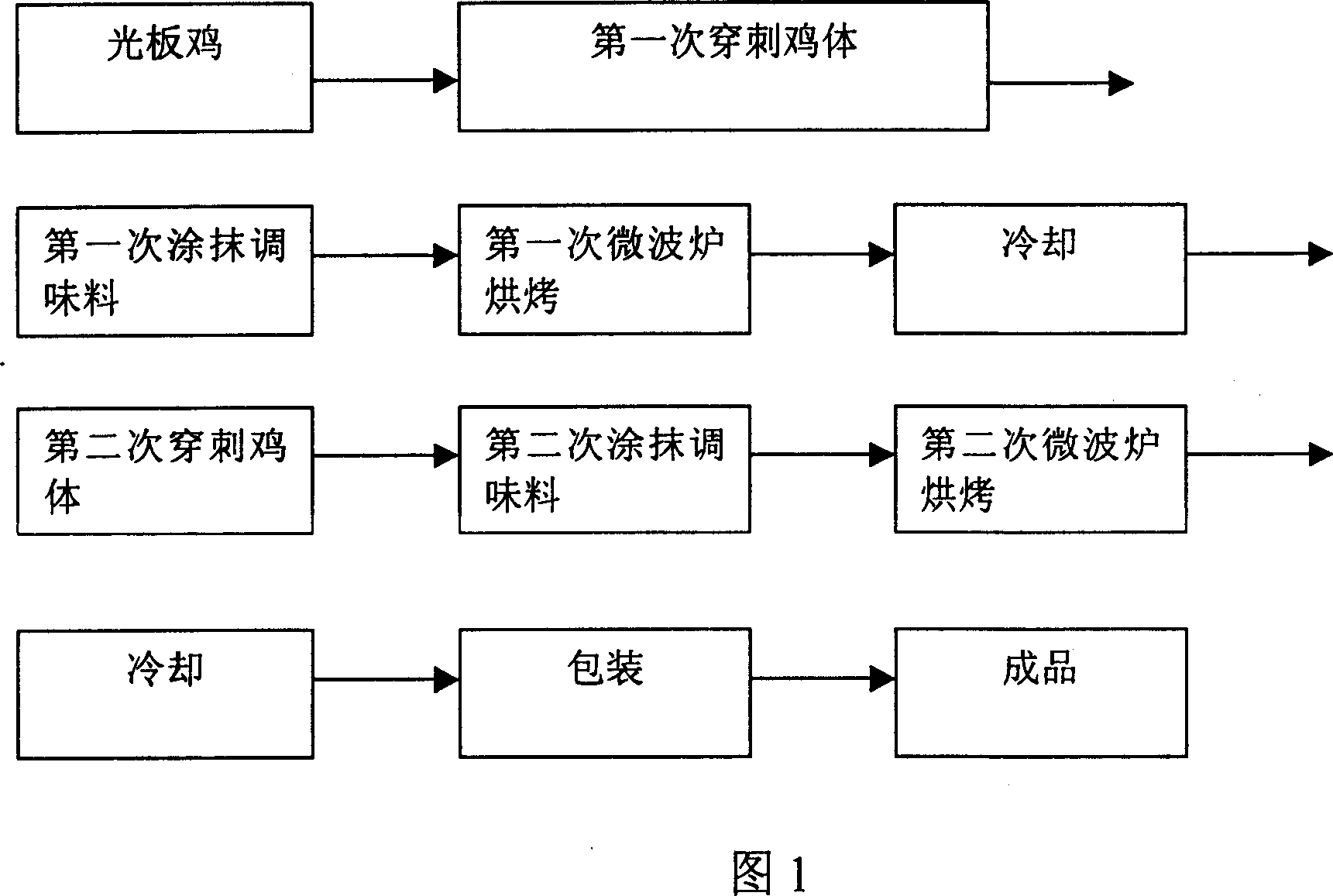

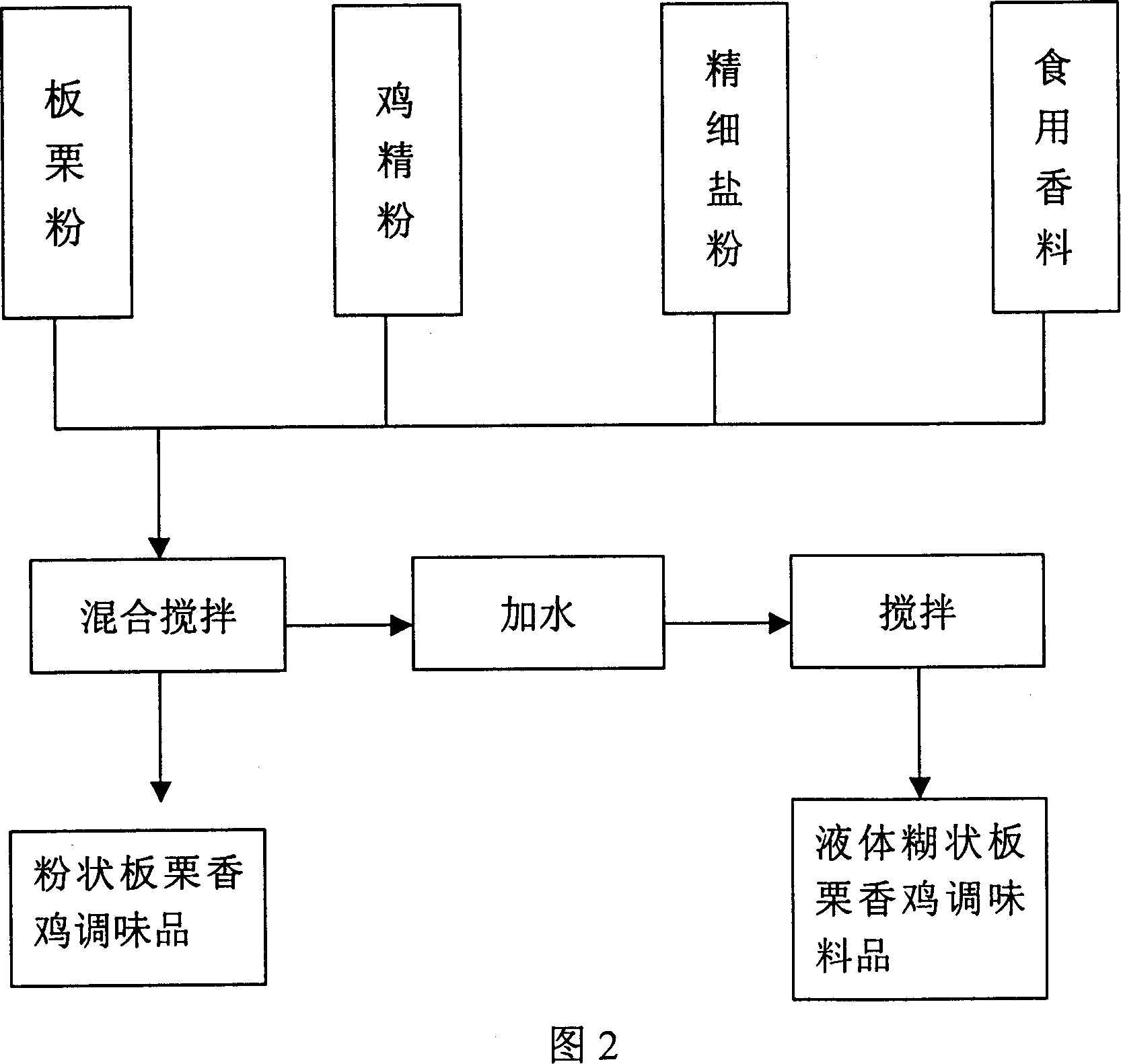

A chicken prepared by chestnut and preparation method thereof

The invention relates to a chestnut chicken and relative preparation. Wherein, it uses healthy chicken, uses chestnut powder as quelite and other findings, to be baked in microwave oven; and the preparation comprises that: puncturing the chicken, coating quelite, baking it in microwave oven; coating the quelite again, baking in microwave oven; cooling, packing. The invention can mix the chestnut chicken, chickens' extract, salt, and flavouring essence. The invention can widen the chestnut application with low cost.

Owner:詹月星

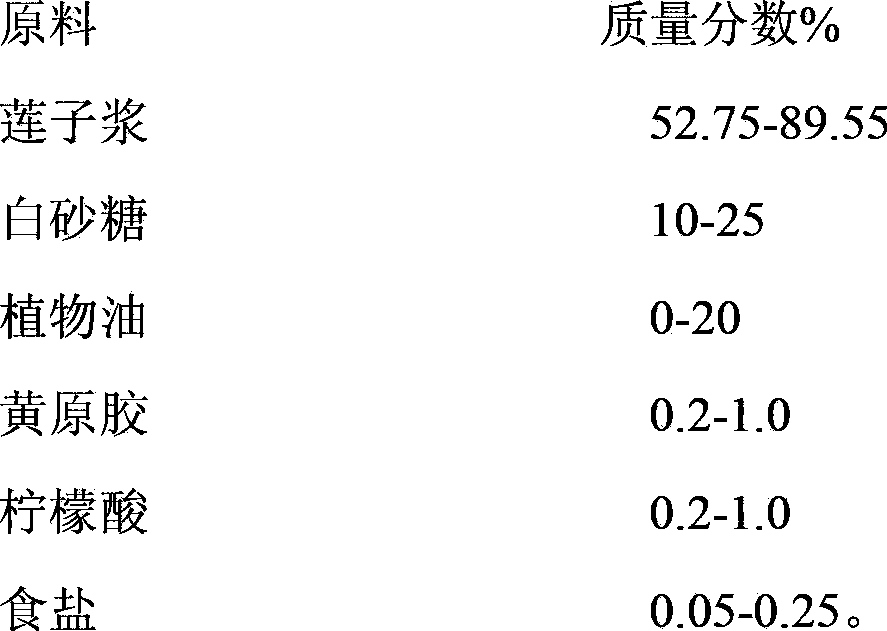

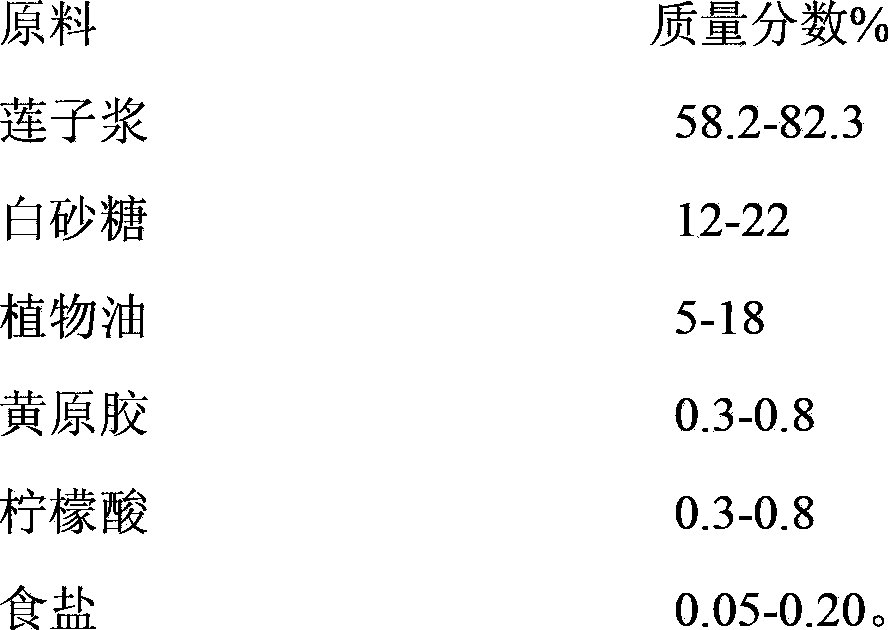

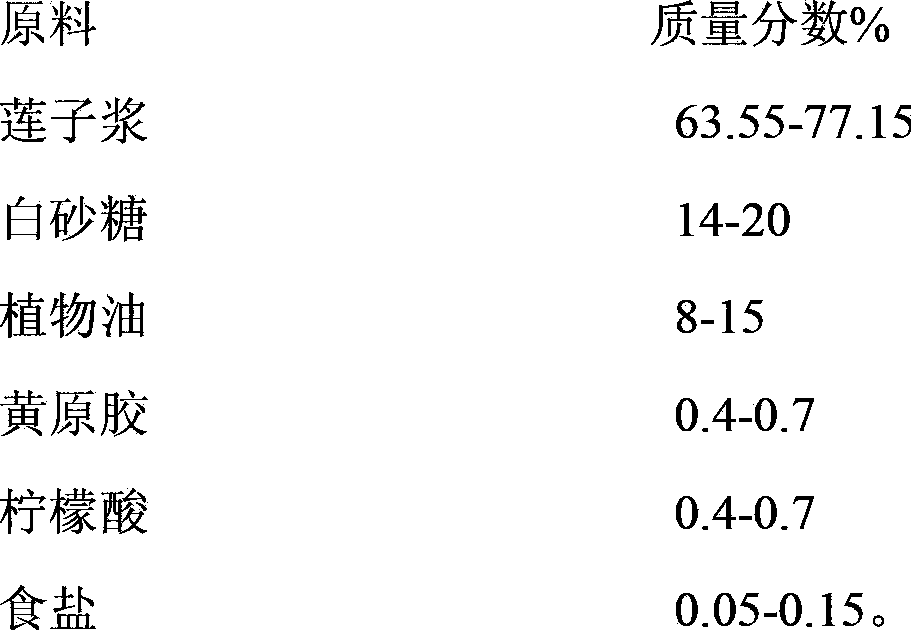

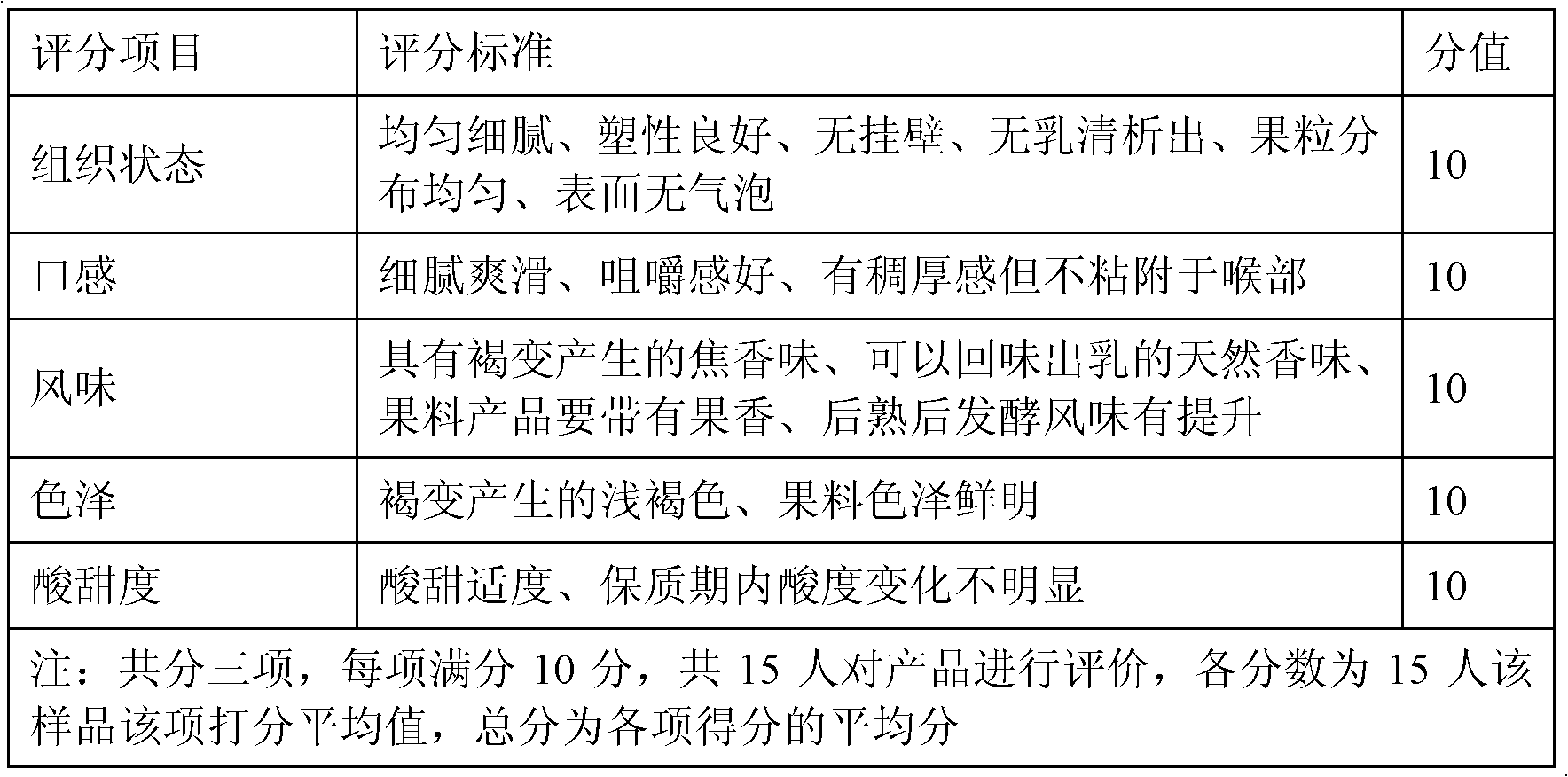

Low-sugar lotus-seed sauce and processing method

ActiveCN103876106ADevelop market valueIncrease profitSugar food ingredientsInorganic compound food ingredientsBiotechnologyColloid

The invention discloses a production method for a low-sugar lotus-seed sauce. The low-sugar lotus-seed sauce is composed of lotus seed pulp, white sugar, plant oil, xanthan gum, citric acid and table salt. The production method comprises steps: A, pretreatment of raw materials, specifically selecting normal-color decay-free dry lotus seeds, removing plumule, immersing with water to soften lotus seeds by enabling lotus seeds to absorb water; B pre-cooking, specifically heating immersed lotus seeds and water in a pressure cooker to fully soften lotus seeds, and pulping; C pulping and colloid milling, specifically pulping pre-cooked lotus seeds by employing a high-speed tissue disintegrator, putting in a colloid mill for milling; D, blending and colloid milling, specifically heating lotus seed pulp under one atmospheric pressure to boiling, adding table salt during heating, then adding citric acid and potassium sorbate, and controlling the temperature of the sauce; and E, loading, sealing, sterilizing and cooling for obtaining the low-sugar lotus-seed sauce. The low-sugar lotus-seed sauce is abundant in nutrition, the method is easily available, the operation is convenient, the lotus-seed sauce is attract in mouthfeel and flavor and low in cost, the lotus seed products are enriched, the market value of lotus seeds is developed, and the development of lotus seed industry is driven.

Owner:HUAZHONG AGRI UNIV

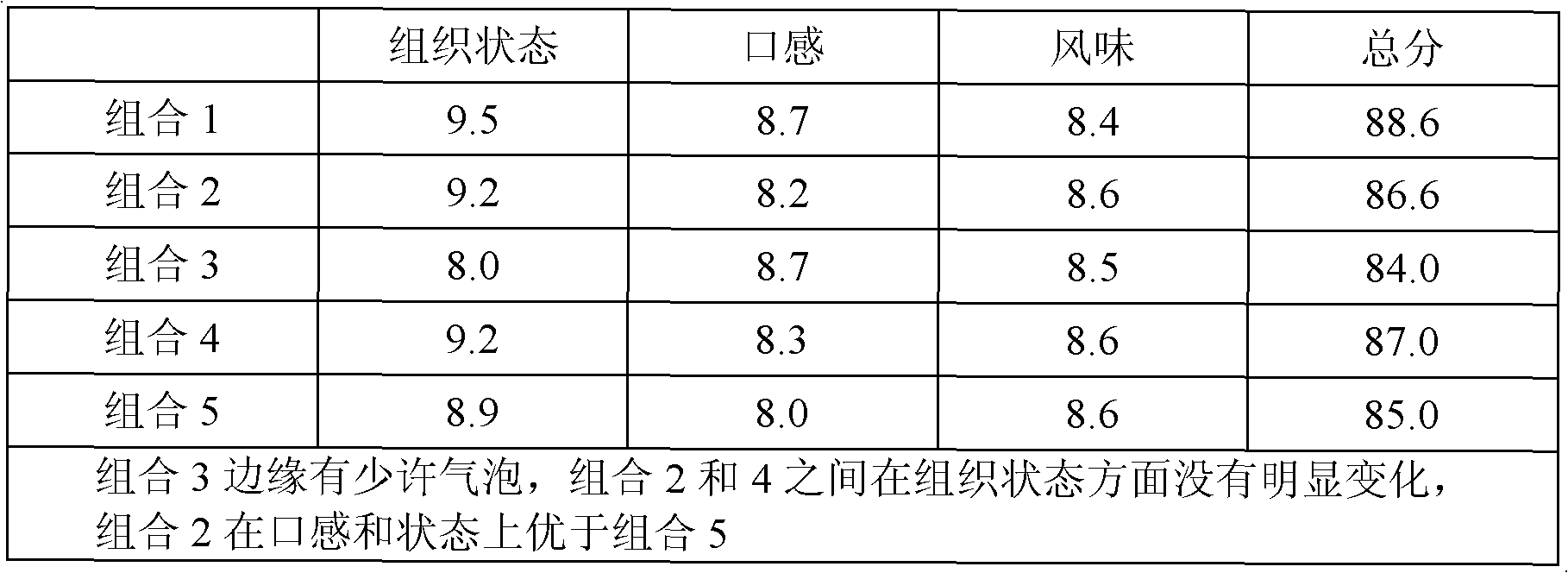

Partly skimmed cheese and preparation method thereof

The invention relates to partly skimmed cheese and a preparation method thereof. Each 100 parts of the partly skimmed cheese consists of the following raw materials by weight: 10 to 90 parts of whole milk powder, 750 to 860 parts of fresh milk, 20 to 50 parts of milk protein powder, 10 to 80 parts of inulin, 30 to 90 parts of sweetener, 5 to 15 parts of stabilizer and 10 to 15 parts of mixed lactobacillus starter. The invention also provides a preparation method of the partly skimmed cheese. The partly skimmed cheese is prepared by scientifically and effectively combining fresh cheese, nonenzymatic browning and the inulin, has the characteristics of soft and unique flavor, smooth mouthfeel, simple and elegant color, low cost and the like, and also has good nutritional and healthy functions and high market value.

Owner:INNER MONGOLIA YILI INDUSTRIAL GROUP CO LTD

Preserved mulberry fruit and preparation method thereof

InactiveCN102726583AWide variety of sourcesSimple processConfectionerySweetmeatsAdditive ingredientSnack food

The invention discloses a preserved mulberry fruit manufactured by using mulberries as a main raw material, belonging to snack food, and a preparation method of the preserved mulberry fruit. The specific processes are as follows: selecting ripe mulberry fruits, washing by clear water in order to remove soil and sand, soaking to protect color, soaking to harden, soaking, standing, dropping sugar, drying at the temperature of lower than 55 DEG C till the water content is less than 20%, and cooling to obtain product. The preserved mulberry fruit has the advantages of wide raw material resource and simple process, so the preserved mulberry fruit is a mulberry fruit highly-processed nutritious product; and the rich mulberry resource in our country is used completely. The obtained product has sweet and sour taste, is nutritious, contains functional components such as resveratrol which are capable of preventing cardiovascular diseases and resisting cancers, and thus the preserved mulberry fruit is the snack preserved fruit food integrated with nutrition and healthcare function.

Owner:徐州林泉绿色食品饮料厂

Ginseng saponin series dairy product and production process thereof

The invention provides a ginseng saponin series extract product and process for preparation comprising, proceeding micro-encapsulation embedding process to ginseng saponin through double agglomeration method microcapsule granulating technology, thus obtaining ginseng saponin capsule, charging milk product into belt stirrer for preheating, adding cane sugar, stabilizer for hydration treatment, stirring to fully dissolve the materials, hydrating the colloid completely, subjecting ginseng saponin microcapsule to disinfection and cooling down, charging in and mixing evenly, circulation stirring, cooling down and fixing volume to required production quantity. The invention can be applied to increase the technological content and added value for the dairy product manufacture.

Owner:广泽乳业有限公司

Method for processing preserved kudzu root

InactiveCN101496551AGood nutrition and health functionKeep the fragrance of glutinous riceConfectionerySweetmeatsSugarBiology

The invention relates to a method for processing preserved kudzuvine roots, which prepares the preserved kudzuvine roots by using fresh and tender kudzuvine roots as a raw material and through the steps of washing, peeling, cutting, blanching, sugar boiling, baking and the like. The method keeps the original waxy powder fresh and fragrant and health-care nutrients of the kudzuvine roots and is convenient and low in cost. The preserved kudzuvine roots are convenient to eat.

Owner:余芳 +1

Diaphragma juglandis fructus vinegar and preparation method thereof

InactiveCN105936867AThe formula is scientific and reasonableComprehensive nutrition and health functionsDigestive systemVinegar preparationMedicinal herbsKidney

The invention discloses a preparation method of a diaphragma juglandis fructus vinegar. The preparation method comprises the following steps: soaking, boiling, cooling through spraying water, performing saccharification and alcoholic fermentation, extracting traditional Chinese herbals by ultrasonic waves, carrying out vinegar fermented grain solid fermentation, spraying vinegar, decocting vinegar, and filling vinegar into bottles. The formula is scientific and reasonable, the nutritional and healthcare functions are comprehensive, moreover, the vinegar has the healthcare functions of tonifying kidney, promoting sperm generation, preventing aging, reliving fatigue, and enhancing the immunity, and meets the requirements of consumers, at the same time, the adopted traditional Chinese herbals have prominent medicinal effects and can be used as food; the raw material resources are wide, and the raw materials are safe, and do not have any side or toxic effect.

Owner:JIANGSU HENGSHUN VINEGAR IND

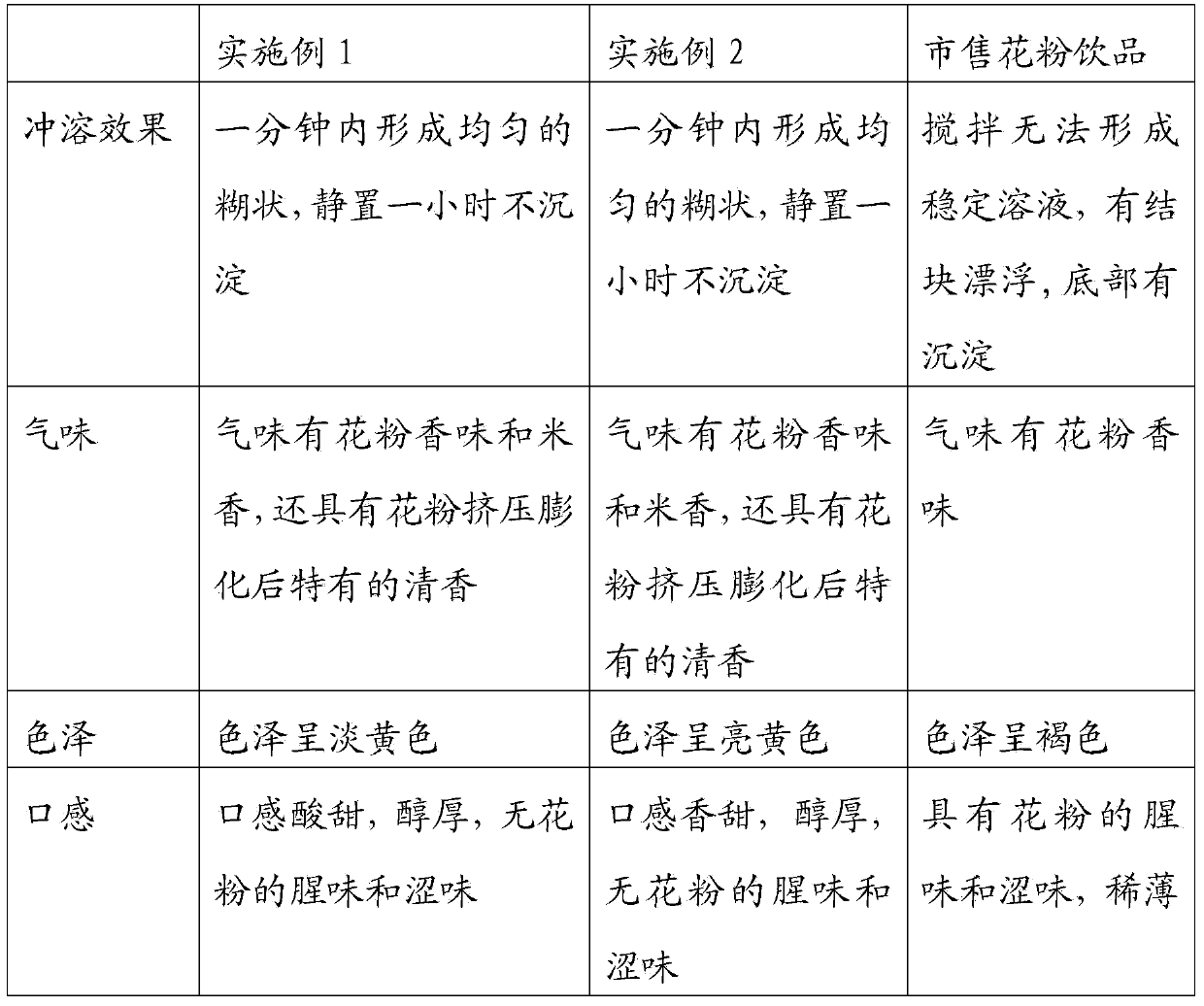

Pollen and fruit and vegetable nutrition powder and preparation method thereof

ActiveCN104187603AGood nutrition and health functionAppropriate tasteFood preparationPollenDietary fibre

The invention relates to pollen and fruit and vegetable nutrition powder and a preparation method thereof. The pollen and fruit and vegetable nutrition powder comprises, by weight, 45-55% of pollen, 25-35% of fruit and vegetable powder, 10-20% of puffed rice flour and 5-10% of puffed buckwheat powder. The pollen and fruit and vegetable nutrition powder combines a miniature nutritional library of the pollen and the seventh nutrient-dietary fibers of the fruit and vegetable powder, improves nutritional and health-care functions to a human body, blends a uniformly dispersed nutritional food with an appropriate taste, makes up the disadvantages that the broken pollen tastes bitter and are liable to form clusters, can be accepted by a user easily, and fully plays the use values of the pollen and the fruit and vegetable powder.

Owner:SHANDONG YITELI BIOTECH CO LTD

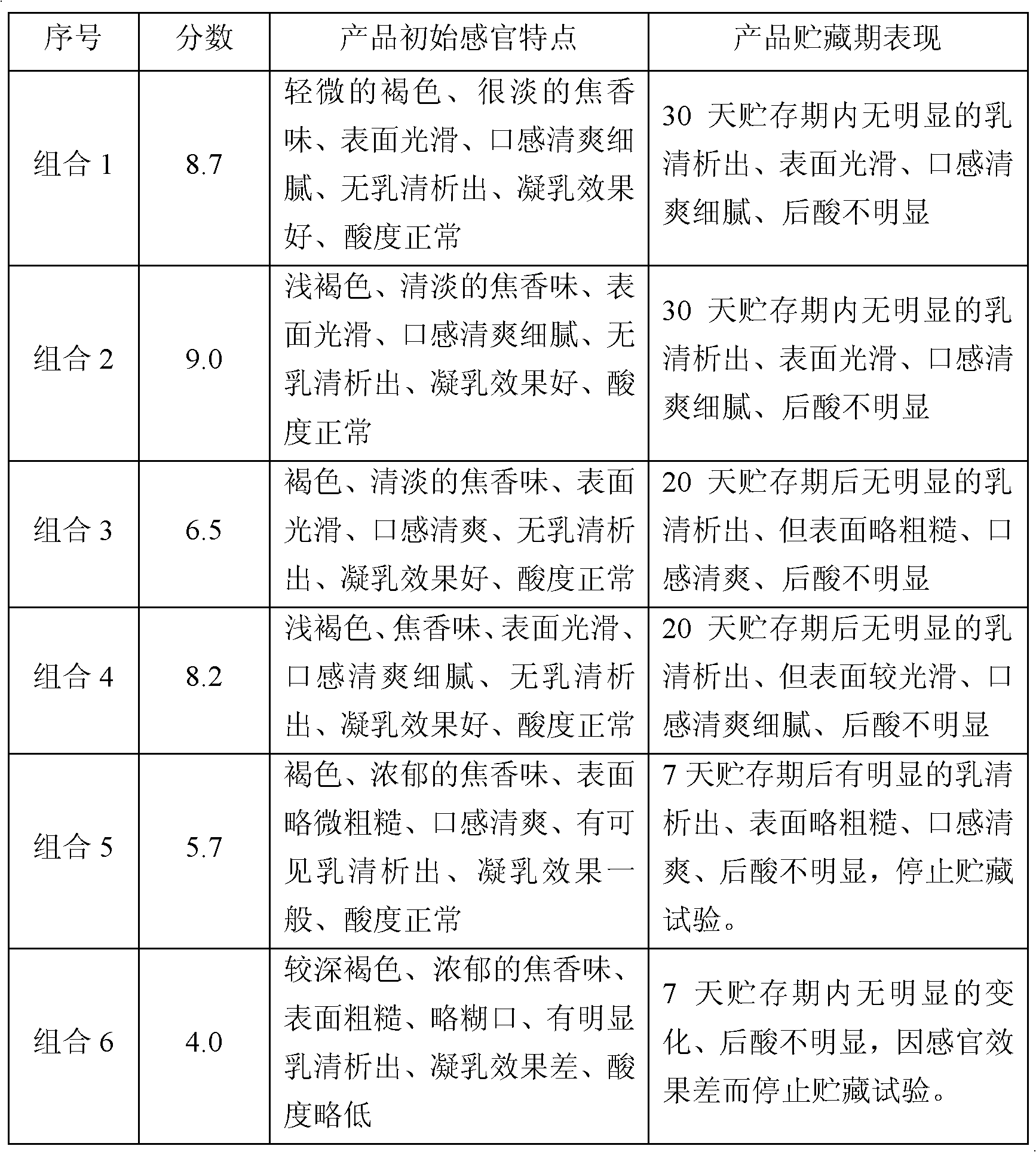

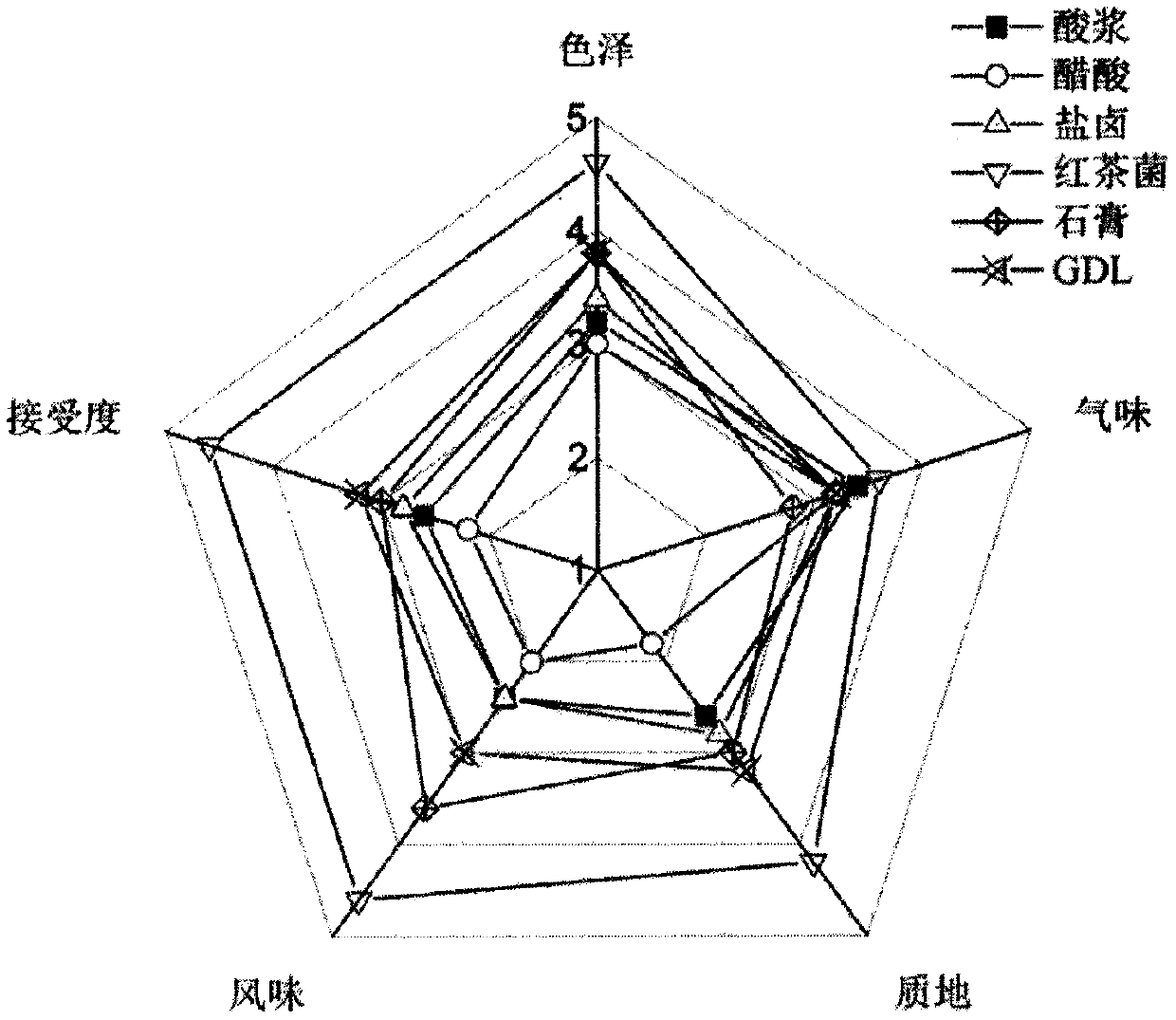

Tea fungus bean curd and production method thereof

The invention discloses tea fungus bean curd and a production method thereof. The method comprises the following steps that 1, tea water with sugar is fermented with tea fungi until the pH value is 2.8-3.6, and a tea fungus solution and a tea fungus film are obtained; 2, the tea fungus solution is diluted with water until the pH value is 3.8-4.0, and the tea fungus solution with the pH value of 3.8-4.0 serves as a bean curd coagulant; 3, the tea fungus film is pulped; 4, soybeans are cleaned, washed, soaked, pulped, filtered and added into the pulped tea fungus film, and after boiling, cookedsoybean milk is obtained; 5, the temperature of the soybean milk is kept to be 85 DEG C or above, coagulation is conducted with the tea fungus solution until the phenomenon that supernatant is separated out is observed, after standing for 10-15 minutes, the bean curd is poured into a frame in which a bean curd cloth is laid, the frame is hermetically wrapped with screen cloth, the screen cloth isflattened, self-drained and pressurized, the pressure is maintained, press forming is conducted to obtain acid slurry bean curd. The tea fungus bean curd is thick in tea aroma, uniform in texture andsufficient in elasticity, has the nutritive and health-care functions of bean curd and tea fungi, has good cooking processing performance, and has a wide market porspect.

Owner:JIANGSU ACADEMY OF AGRICULTURAL SCIENCES

Bee product wine and preparation method thereof

The invention relates to a preparation method of a bee product wine. The method comprises the steps of: for fine powder raw materials, mixing 1% of bee pollen, 0.5% of royal jelly powder, 0.5% of drone pupa powder, 0.5% of queen bee larva powder and 0.2% (weight) of others with 94%-98% (weight) of high quality strong-flavor Tequ liquor in proportion, conducting cold extraction, and after 15-20 days, carrying out coarse filtration, fine filtration, fine filtration (or ultrafiltration) after freezing, and cellaring aging treatment respectively, thus obtaining a finished product. According to the invention, the bee products involved in the formula are subjected to superfine grinding and then to accurate metering preparation, thus ensuring qualitative and quantitative control of the product. And the defects that difficult accurate control of the quality and quantity of raw materials due to necessary employment of a lot of preservative during use of fresh products in traditional methods can be avoided.

Owner:刘笑麟

Convenient and instant conditioning penaeus orientalis production method

InactiveCN104814476AIncrease natural organic calcium contentReduce consumption costFood preparationFlavorPenaeus orientalis

The present invention discloses a convenient and instant conditioning penaeus orientalis production method which includes the following specific steps: 1) washing, draining and blanching penaeus orientalis; 2) removing heads, tails, shells and intestines of the blanched penaeus orientalis to obtain penaeus orientalis meat and shells, and rinsing and draining the meat and shells; 3) preparing penaeus orientalis shell powder with an average particle size less than 30 mu m; 4) cutting the obtained penaeus orientalis meat in step 2 into segments and vacuum microwave drying the penaeus orientalis meat segments; 5) preparing seasoning liquid; 6) preparing a suspension by mixing and stirring the penaeus orientalis powder and the seasoning liquid evenly, and adding the penaeus orientalis meat into the suspension to conduct pressurized impregnation treatment; and 7) vacuum microwave drying and vacuum packaging. The convenient and instant conditioning penaeus orientalis production method has small processing energy consumption and less nutrient loss, and can ensure good quality and improve flavor and mouth feel of the penaeus orientalis.

Owner:ZHEJIANG PHARMA COLLEGE

Puerpera nourishing health care chicken and preparation method thereof

InactiveCN101253985AEasy to manufactureNutritional diversityFood preparationMedicineAdditive ingredient

The invention belongs to healthcare food and relates to a tonic nutritional healthcare chicken for a lying-in woman and a preparation method thereof, in particular to the making of poultry food. The method takes a hen during the laying period as a raw ingredient chicken; the whole hen after being slaughtered is irradiated by microwave and fully soaked in extracting solution of tonic nutritional healthcare products, and then the profile finishing, the disinfection as well as sterilization, and the packing are performed, thereby providing the ideal food of the tonic nutritional healthcare chicken used for the lying-in woman and the preparation method thereof. The tonic nutritional healthcare chicken has the advantages of rich nutrition, convenient making for a consumer, complete functions of regulating, nourishing, and nutritional healthcare, scientific and reasonable ingredient adoption as well as compatibility, and deliciousness. The tonic nutritional healthcare chicken is helpful to the physical recovery, physiological function regulation and breast-feeding of the lying-in woman.

Owner:张冠婕

Nutritional health-care steamed bread and process for processing same

InactiveCN101991044ANutritional balanceGood nutrition and health functionFood preparationYeastAdditive ingredient

The invention discloses nutritional health-care steamed bread and a process for processing the same. The nutritional health-care steamed bread is made of raw materials of wheat fine powder, Chinese yam juice, honey and active dry yeast. The nutritional health-care steamed bread is prepared by kneading, respectively extruding, moulding, fermenting, steaming, thoroughly cooling, quickly freezing and packaging the prepared Chinese yam juice and flour. Compared with the traditional steamed bread, the nutritional health-care steamed bread contains more nutritional components by adding the Chinese yam juice and honey into the raw materials, has more balanced nutrition so that the steamed bread which is daily staple food is endowed with the nutritional health-care function and achieves the aims of improving human body function and building the body.

Owner:王家宏

Preparation method of compound red jujube and Chinese wolfberry beverage

InactiveCN107788296AColor orangePure tasteNatural extract food ingredientsFood ingredient functionsPectinaseSucrose

The invention discloses a preparation method of red dates and wolfberry compound beverage, which comprises the following steps: (1) after cleaning the red dates, remove the pits, cut into pieces, add water, add pectinase, stir at constant temperature, then centrifuge, and take the upper layer Clear liquid to obtain jujube juice; (2) After cleaning the wolfberry, add it to water, let it stand at 40-60°C for 40-60min, then make a slurry, and then centrifuge it, and take the supernatant to obtain wolfberry juice; (3) Mix jujube juice, wolfberry juice, citric acid, sucrose, xanthan gum, and sodium alginate, stand at 60-80°C for 30 minutes, then stir for 40-60 minutes to obtain a beverage slurry; (4) combine step (3) The obtained beverage slurry is homogenized at 60°C; (5) sterilization and packaging. The beverage prepared by the invention has orange color, pure taste, unique aroma of jujube and wolfberry, sweet and sour taste, excellent nutrition and health care functions, and simple production process.

Owner:SHAANXI HUANKE BIOLOGICAL TECH CO LTD

Multifunctional high-efficient calcium replenishing agent and preparation thereof

The invention relates to a nutrient supplement for calcium supplementation, in particular to a multi-functional high-efficient calcium supplemental agent and a preparation method thereof which belong to the field of nutritious and health care products. The product of the invention selects inorganic calcium salt, L-ascorbic acid, L-aspartic acid for carrying out the reaction to prepare L-ascorbic acid-L-aspartic acid calcium; and the L-ascorbic acid-L-aspartic acid calcium can be prepared into health care foods with different forms such as tablets, granules, capsules, oral liquor and other after being added with necessary excipients. The product has good taste, no bitter taste and no gastrointestinal tract stimulation; the product has easy absorption, good safety and multiple nutritious health care functions. The product can more easily enter various parts of the human body through the passive diffusion, the transport or active transport and other different modes when in lack of calcium of the human body particularly, thereby meeting the needs on the calcium element by various tissues of the human body.

Owner:辽宁美天佳生物科技有限公司

Method for preparing yoghourt by utilizing lactobacilli coming from pickle and yoghourt prepared by same

ActiveCN105166041AImplement heterogeneous applicationsImprove acid resistanceMilk preparationLiquid mediumFreeze-drying

The invention provides a method for preparing yoghourt by utilizing lactobacilli coming from pickle. The steps are as follows: (1) a lactobacillus strain is screened out from the pickle; (2) the screened lactobacillus strain is inoculated into MRS liquid medium and cultured to be multiplied, bacterial liquid which is obtained by multiplication culture is centrifuged, supernate is then discarded, so that thalli are obtained, the thalli and sterilized aqueous freeze-drying protectant solution are mixed uniformly and frozen into the solid state, and then, after freeze drying, starter is obtained; (3) white granulated sugar and milk powder are dissolved into water, homogenized, sterilized and regulated to the temperature of 30DEG C to 40DEG C, so that modified milk is obtained, the starter is dissolved into sterile water to form starter solution, the starter solution and the modified milk are mixed uniformly, filled into a vessel, sealed and kept still to ferment under 40DEG C to 42DEG C until the liquid in the vessel is changed into curd, the curd is then placed under 2DEG C to 6DEG C for 24 to 48 hours, and thereby the yoghourt is obtained. The number of living lactobacilli in the yoghourt prepared by the method is large, and the yoghourt has high nutritional and health-care value.

Owner:SICHUAN UNIV

Spotted deer velvet nucleic acid series dairy product and production process thereof

The invention provides a sika deer velvet nucleic acid series extract product and process for preparation comprising, proceeding micro-encapsulation embedding process to nucleic acid through double agglomeration method microcapsule granulating technology, thus obtaining sika deer velvet nucleic acid capsule, charging milk product into belt stirrer for preheating, adding cane sugar, stabilizer for hydration treatment, stirring to fully dissolve the materials, hydrating the colloid completely, subjecting the sika deer velvet nucleic acid microcapsule to disinfection and cooling down, charging in and mixing evenly, circulation stirring, cooling down and fixing volume to required production quantity. The invention can be applied to increase the technological content and added value for the dairy product manufacture.

Owner:广泽乳业有限公司

Method for preparing ginkgo, Chinese wolfberry and astragalus health-care wine

InactiveCN102061239AEasy to prepareImprove economyAnthropod material medical ingredientsDigestive systemBiologyLycium chinense

The invention discloses a method for preparing ginkgo, Chinese wolfberry and astragalus health-care wine, which comprises the following steps of: cutting 80 to 100 parts of ginkgo pulp, 15 to 20 parts of ginseng, 25 to 30 parts of astragalus, 35 to 40 parts of Chinese wolfberry, 25 to 30 parts of liquoric root and 10 to 20 parts of mint into slices or grinding into coarse powder, and putting into a container; adding 15 to 20 parts of honey into the container; blending by using 800 to 1,000 parts of distilled spirit with alcoholic strength of between 50 and 60 degrees, sealing the container and soaking; stirring once at intervals of 1 to 2 days; immersing for 30 days, and filtering decoction dregs (tablets) out; and standing at the normal temperature for 10 to 20 days for clarification, and filtering to obtain the ginkgo Chinese wolfberry astragalus health-care wine. The method has the advantages of simplicity of preparation and good economy, the health-care efficiency of the ginkgo can be played fully by process science, and the prepared wine can produce an obvious health-care effect after long-term drinking.

Owner:葛雪华

Compound cereal drink and processing technology thereof

InactiveCN104544447AGood nutrition and health functionHigh activityFood preparationPearl barleyWarm water

The invention discloses a compound cereal drink. The compound cereal drink disclosed by the invention comprises the following components in parts by weight: 40-60 parts of high-quality broken pearl barley, and 40-60 parts of high-quality barley malt. A processing technology of the compound cereal drink disclosed by the invention comprises the following steps: 1, cleaning the broken pearl barley, activating in warm water at 30 DEG C for 24 h, adding water to grind into thick liquid according to the ratio of 1:(3-5), and screening through a 40-60-mesh sieve for later use; 2, removing purities and cleaning the barley malt, immersing and activating in warm water at 30 DEG C for 0.5 h, and adding water to break according to the ratio of 1:(3-5) for later use; 3, mixing and keeping the temperature: mixing pearl barley slurry with barley malt slurry, adjusting pH to 5.1-5.3, heating to increase the temperature to 50-55 DEG C, keeping the temperature for 1.5-2.0 h, then, adding CaC12 to adjust pH to 5.6-5.7, increasing the temperature to 65-70 DEG C, keeping the temperature for 1.5-2 h, grinding into thick liquid after boiling, and filtering through a 80-mesh sieve; and 4, blending: blending according to taste requirements, adding a stabilizing agent, homogenising, sterilizing, and cooling. According to the invention, the pearl barley is broken, immersed and activated; a part of broken pearl barley is replaced by the barley malt; and thus, the compound cereal drink disclosed by the invention is obtained through raw material conversion by utilizing the complementary action of abundant natural endogenous enzymes of the pearl barley and the barley malt.

Owner:GUIZHOU UNIV

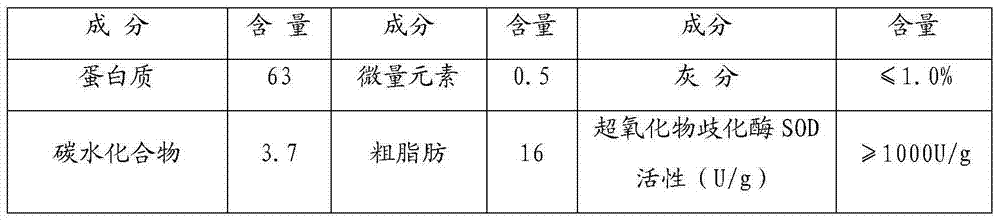

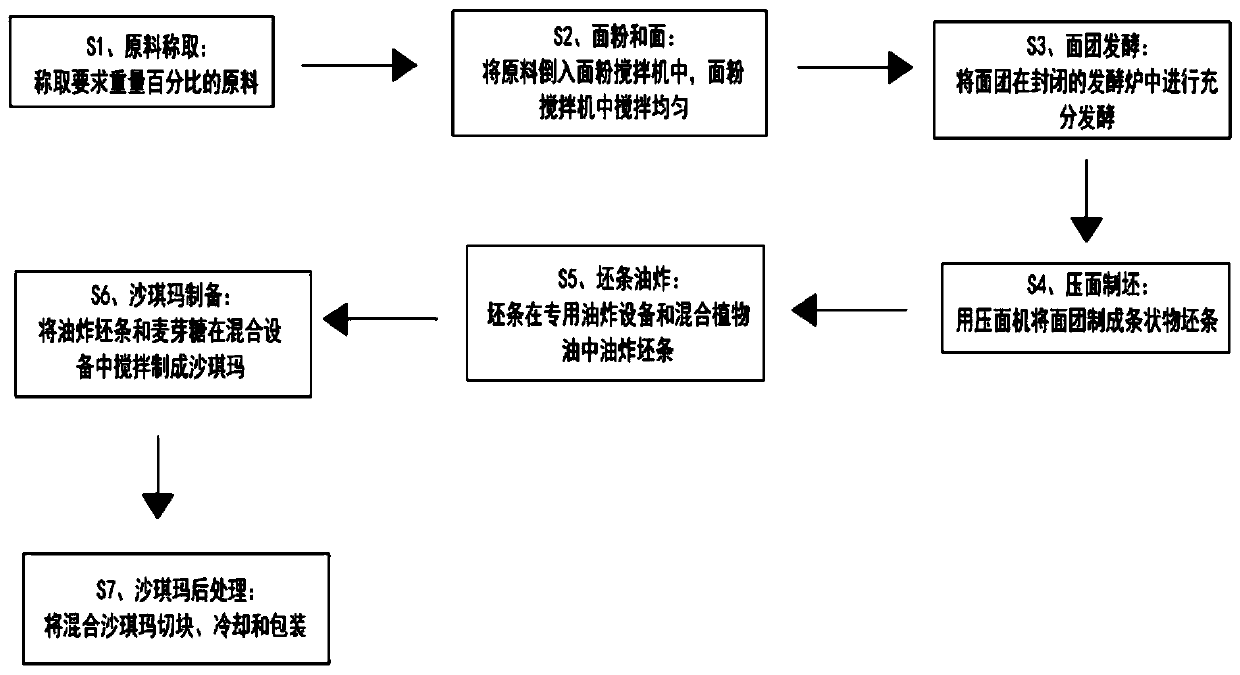

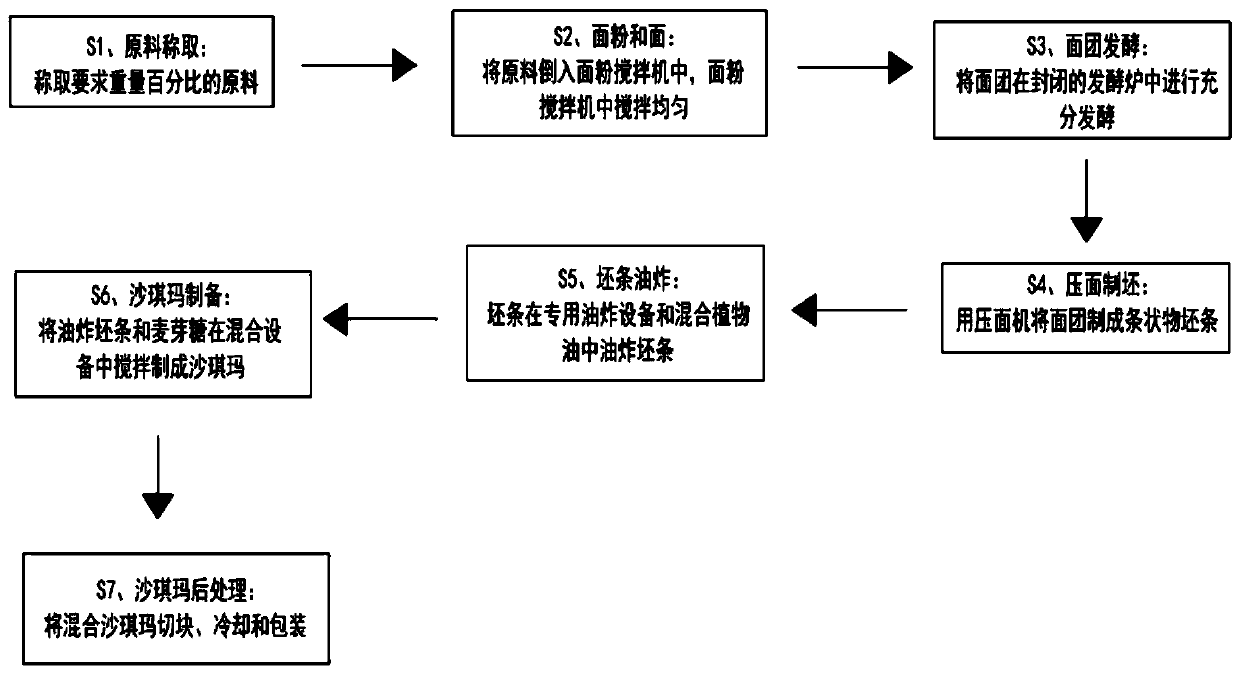

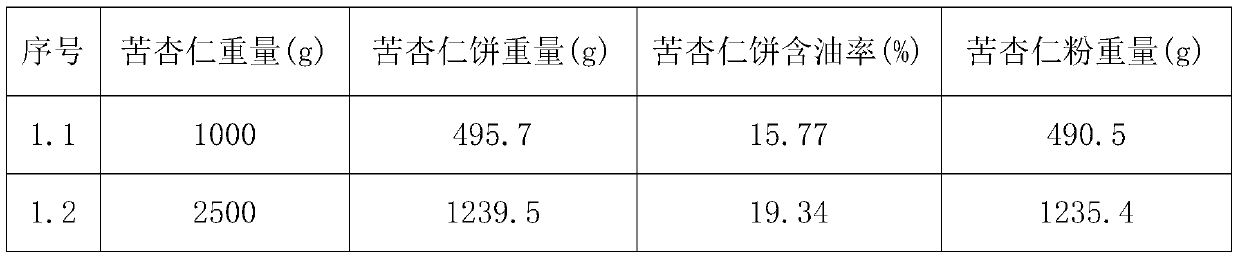

Sachima and preparation method thereof

ActiveCN111165526AReduce oil contentFully preserve nutrientsDough treatmentFatty-oils/fats refiningBiotechnologyVegetable oil

The invention discloses a preparation method of Sachima, which comprises the following steps: by using tartary buckwheat flour and wheat flour as main raw material, adding a certain proportion of oneor more of vital wheat gluten, apricot kernel powder, peach kernel powder, lily powder, lotus root starch and kudzu vine root powder as modified auxiliary materials, and carrying out specific formingand frying preparation methods to obtain the Sachima. The Sachima has the characteristics of being good in leavening degree, crisp and soft in mouth feel, fine and uniform in internal tissues and instant in melting in the mouth, and also have rich nutrition and health-care functions; secondly, according to the deep-frying preparation method of the Sachima, the food-grade anti-sticking agent, the defoaming agent and the stabilizing agent are added, so that the deep-frying performance of the caramel treats is effectively improved, the loose, soft and good-integrity caramel treats are obtained, and meanwhile, the service life of the vegetable oil for deep-frying is effectively prolonged.

Owner:贵州问候自然食品有限公司

Complex flavouring with function of adding saltiness, adding freshness and containing less sodium

ActiveCN101243861BReduce sodium chloride contentSimplify cooking operationsFood shapingFood preparationCooking processLow sodium

The invention discloses a low-sodium functional compound seasoning which can increase the taste of salty and savory. The invention is characterized in that the low-sodium salt is the main raw material on the basis of which one or a plurality of functional nutrients that can increase the taste of savory and salty, and one or a plurality of savory materials are added; then after mixing, stirring, and granulating, the compound seasoning is made. The compound comprises 20 to 80 portions weight of low-sodium salt, 10 to 30 portions weight of functional nutrient and 3 to 15 portions weight of savory materials. Therefore, the compound seasoning has the advantages of effectively reducing the ingestion of NaCI, outstanding flavoring effect and nutrient function. What's more, the invention can be operated simply for the taste of salty, savory and delicious can be got at a time in the process of cooking.

Owner:上海东南清宫食品工业有限公司

Fruit chilli paste and preparation method thereof

The invention relates to fruit chilli paste and a preparation method thereof. The fruit chilli paste is prepared from, by weight, 55-60% of chillies, 5-7% of apples, 5-7% of pears, 5-7% of garlic, 4-6% of ginger, 3-5% of edible oil, 3-5% of mature vinegar, 2.5-4% of dry salted and fermented soya paste, 2.5-4% of edible salt, 1.5-3% of crushed peanuts, 1.5-3% of white sugar, 1-2% of sesame and 1-2%of aginomoto. The preparation method comprises the steps of 1, pretreatment of the raw materials; 2, treatment of the dry salted and fermented soya paste, wherein the dry salted and fermented soya paste is diluted with the mature vinegar, and then the white sugar is added; 3, smashing, wherein the chillies, the apples, the pears, the ginger and the garlic are put into a food processer and smashedinto slurry; 4, boiling, wherein the edible oil and the dry salted and fermented soya paste are heated, the slurry chillies and fruits are boiled for 20 minutes, and the crushed peanuts, the sesame and the aginomoto are added for boiling for 10 minutes; 5, cooling and canning, wherein the fruit chilli paste is prepared through cooling and canning. A chili paste formula is optimized, the taste ofthe chilli paste is improved, the nutritive health care functions are improved, and a new variety is provided for development of chilli foods.

Owner:SHIJIAZHUANG ACADEMY OF AGRI & FORESTRY SCI

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com