Salt gypsum and salty mud solid waste harmless treatment process

A technology of harmless treatment and salt gypsum, applied in the field of salt gypsum treatment, can solve the problems of difficult reuse of salt gypsum and impact on the environment, and achieve the effect of improving enthusiasm and increasing income

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

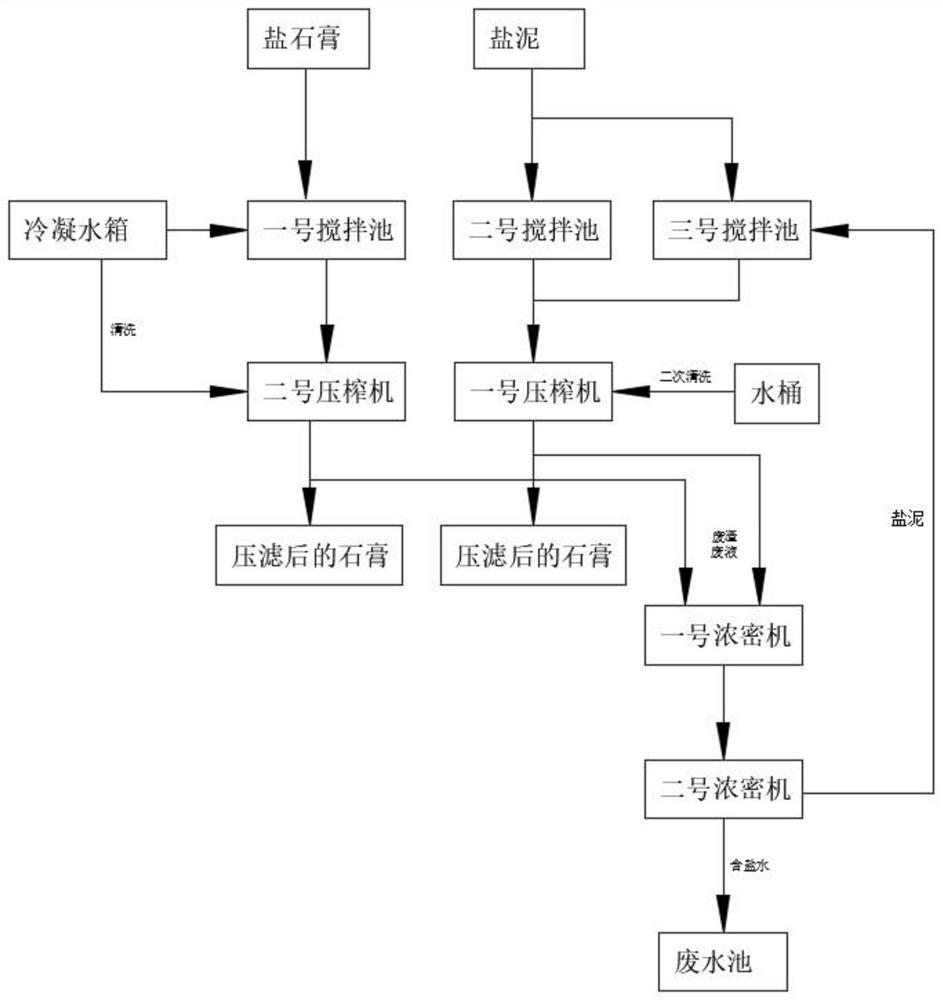

[0024] refer to figure 1 , an embodiment provided by the present invention: a process for the harmless treatment of salt gypsum and salt mud solid waste, comprising steps:

[0025] S1. Put the salt gypsum into the No. 1 mixing tank, and put the salt mud into the No. 2 mixing tank and No. 3 mixing tank;

[0026] S2. The water in the condensate bucket enters the No. 1 mixing tank, and the salt gypsum and water are stirred together

[0027] Add water to dilute the concentration of sodium chloride;

[0028] S3, the stirred salt gypsum slurry is moved from the No. 1 mixing pool to the No. 2 press

[0029] The press presses the gypsum into a gypsum cake, squeezes out the water, and reduces the salt content;

[0030] S4, the No. 2 press discharges the gypsum after pressing, and the waste residue and waste liquid enter the No. 1 thickener;

[0031] S5. The concentrated waste liquid is transferred from the No. 1 thickener to the No. 2 thickener;

[0032] S6. The salt mud after pre...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com