Hydrolyzation post-processing technique during preparation of glyphosate through glycin method

A technology of glycine and glyphosate, applied in chemical instruments and methods, compounds of Group 5/15 elements of the periodic table, organic chemistry, etc., can solve the problems of increasing the total amount of mother liquor, difficult waste water treatment, and high energy consumption, Achieve the effect of increasing surface area, reducing time and reducing energy consumption

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

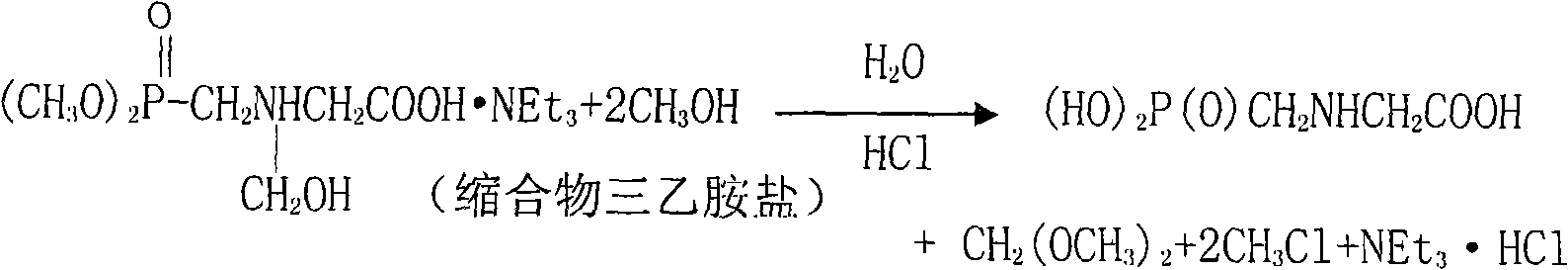

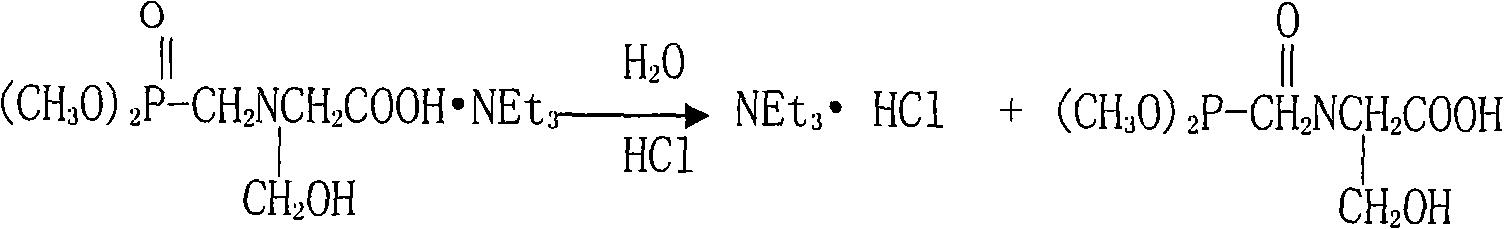

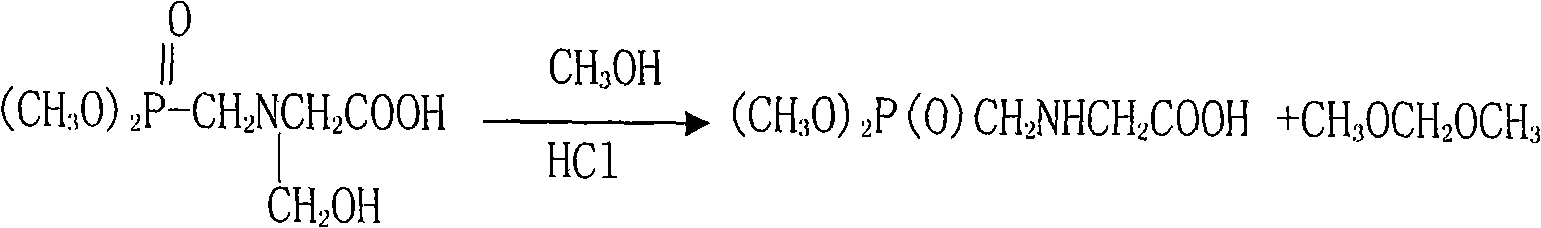

Method used

Image

Examples

Embodiment 1

[0024] While stirring, add 280g of methanol, 85g of triethylamine, 49.5g of paraformaldehyde, 62.5g of glycine, and 109.5g of dimethyl phosphite into the four-necked reaction flask in order to complete the depolymerization, addition, and condensation reactions. Obtain the condensed liquid, directly add 330g of 31% hydrochloric acid (the mol ratio of glycine and hydrochloric acid is 1: 3.4) under agitation and carry out hydrolysis, control temperature when adding acid and be not higher than 45 ℃, treat that after hydrochloric acid adds, begin to slowly heat up, gas phase Condensation was collected in a flask. First, the temperature was raised to 80°C in 140 minutes, and then to 117°C in 130 minutes, and kept for 20 minutes to obtain a hydrolyzed solution.

[0025] Distill the hydrolyzate under reduced pressure, the pressure is 0.025-0.03Mpa, the temperature drops rapidly to 80±3°C, and then rises slowly, it takes 30 minutes, the temperature rises back to 110±2°C, and 150ml of d...

Embodiment 2

[0027] Get methanol 2800kg, triethylamine 850kg, paraformaldehyde 495kg, glycine 625kg, dimethyl phosphite 1095kg reaction to obtain condensation liquid, directly add 30% hydrochloric acid 330g under stirring (the mol ratio of glycine and hydrochloric acid is 1: 3.34) Carry out hydrolysis, control the temperature not higher than 45°C when adding acid, and start to slowly heat up after adding hydrochloric acid. First, the temperature was raised to 80°C in 140 minutes, and then to 117°C in 130 minutes, and kept for 20 minutes to obtain a hydrolyzed solution.

[0028] Pass the hydrolyzate into the flash tank for distillation, control the amount of steam in the flash tank and the amount of hydrolyzate entering the flash tank, so that the temperature in the flash tank is not lower than 80±2°C, and the pressure is 0.08-0.085 MPa. The vacuum distillation took 60 minutes to obtain 1650L of condensed distillate and a mixed solution of hydrochloric acid. The content of hydrochloric aci...

PUM

| Property | Measurement | Unit |

|---|---|---|

| quality score | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com