Sodium sulphate preparation method and sodium sulphate foot structure of evaporator therefor

A technology of evaporating tank and nitre foot, which is applied in the field of concentrated liquid and nitrate foot structure, which can solve the problems of inability to reach Glauber's salt, large heat loss, and high temperature of concentrated liquid, and achieve the effects of lowering temperature, reducing damage, and lowering temperature

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

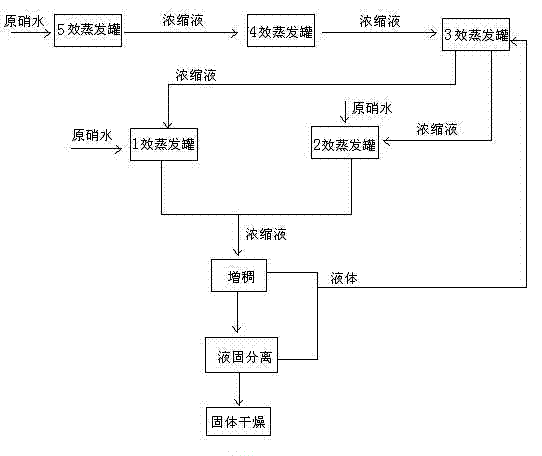

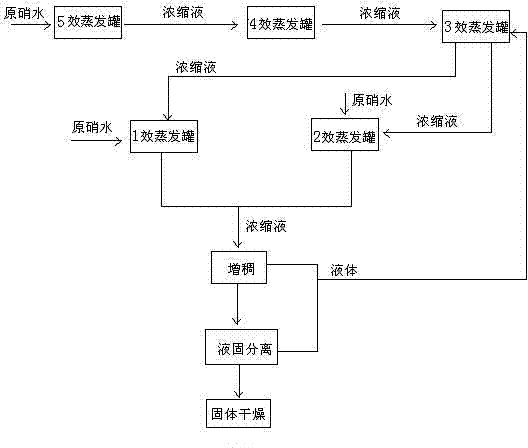

[0019] In this embodiment, five-effect evaporators are used for evaporation, concentration, and crystallization, and the incoming materials of the second-effect and first-effect evaporators all come from three-effect evaporators. The present invention comprises the following steps:

[0020] (1) According to the conventional method, the nitric water is sequentially pumped into the five-effect, four-effect and three-effect evaporating tanks by the nitric water pump for evaporation, concentration and crystallization. The sodium content is 100-120g / L, the temperature of the concentrate in the four-effect evaporator is 60-70°C, the content of sodium chloride in the concentrate is 150-170g / L, the temperature of the concentrate in the three-effect evaporator is 80-90°C, concentrated The sodium chloride content in the liquid is 200-220g / L. The concentrated liquid in the three-effect evaporator is pumped into the second-effect and one-effect evaporator respectively for evaporation, co...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com