Nanometer ferroferric oxide pigment composition and production method thereof

A technology of ferroferric oxide and pigment composition, applied in the field of pigments, which can solve problems such as the inability to apply transparent systems, easy contamination of products, uneven material particles, etc., and achieve the effects of uniform particles, shortening the production process, and reducing energy consumption

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

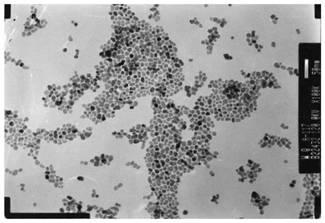

[0041] as attached figure 1 Shown, the present invention discloses a kind of production method of nanometer iron ferric oxide pigment composition, comprises the steps:

[0042] Step 1. Under the action of an external magnetic field, the magnetic field intensity is controlled at 100A / m, and 1 molar part of FeCl 2 The raw materials are added to a container placed in a magnetic field, dissolved in water to obtain FeCl with a mass fraction of 5%. 2 solution;

[0043] Step 2, under the action of an external magnetic field, to the FeCl in step 1 2 The solution is added to 20% NaOH solution, the molar ratio of OH - / Fe 2+ =2.1, stirred for 20min to obtain ferrous hydroxide suspension;

[0044] Step 3, under the action of an external magnetic field, feed air into the ferrous hydroxide suspension in step 2, and control the oxidation rate to be 2% / min, so that the ferrous iron in the ferrous suspension is oxidized to iron black precipitation;

[0045] Step 4. Under the action of ...

Embodiment 2-9

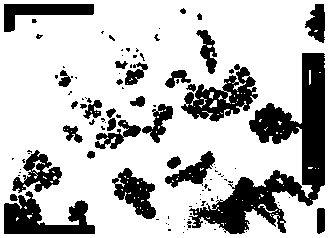

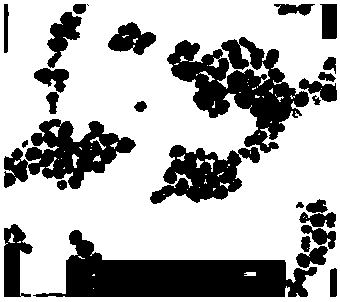

[0050] as attached Figure 2-9 Shown, a kind of production method of nanometer iron ferric oxide pigment composition, its step is identical with embodiment 1, only is that reaction parameter is different, and concrete parameter is as follows table 1:

[0051]

[0052]

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com