Ice for food partial freezing fresh keeping

A food and ice machine technology, applied in food preservation, meat/fish preservation through freezing/cooling, applications, etc., can solve the problems of slow development of micro-freezing preservation technology, inconvenient use of cold chain, high salt content of micro-freezing liquid, etc. , to achieve the effects of long sales distance, delaying ice melting, and stabilizing ice temperature

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

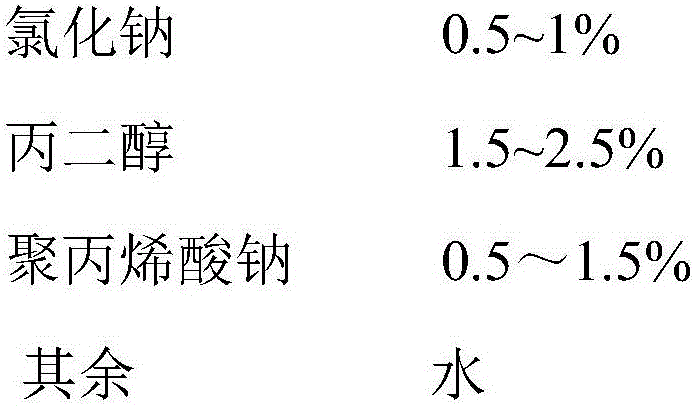

[0018] The components and mass percentages of the ice used for micro-freezing and fresh-keeping are as follows: 0.5% sodium chloride, 2.5% propylene glycol, 1.5% sodium polyacrylate, and 95.5% water.

[0019] During the preparation of fresh-keeping ice, slowly add propylene glycol to sodium polyacrylate, and stir slowly in the same direction while adding, until the sodium polyacrylate is completely dissolved, then add sodium chloride and water to make a mixed solution, and pass through the ice machine Cool to make ice.

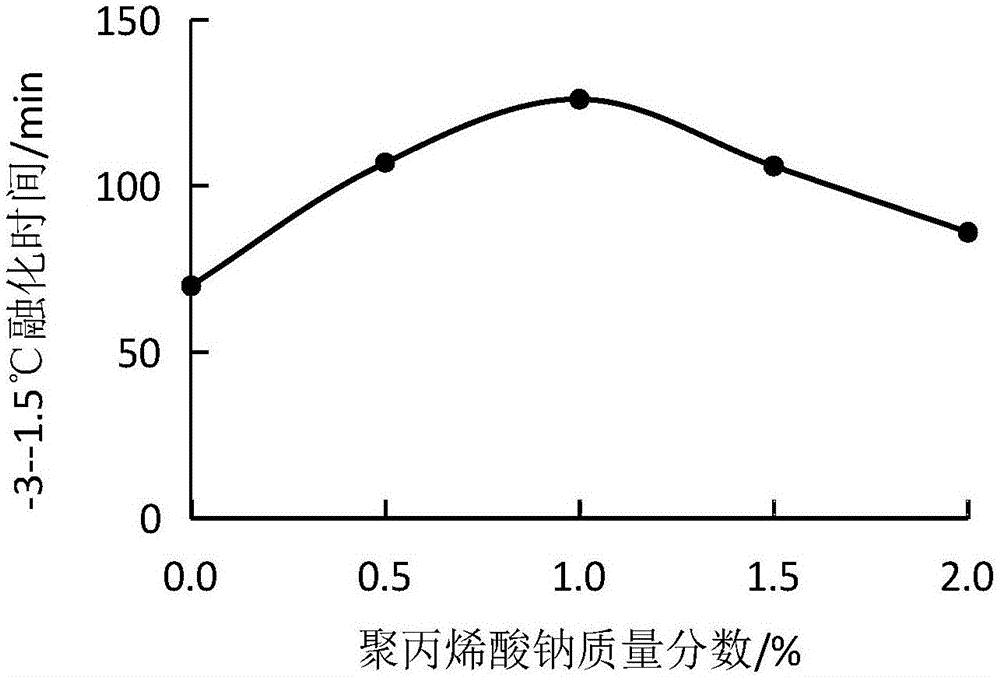

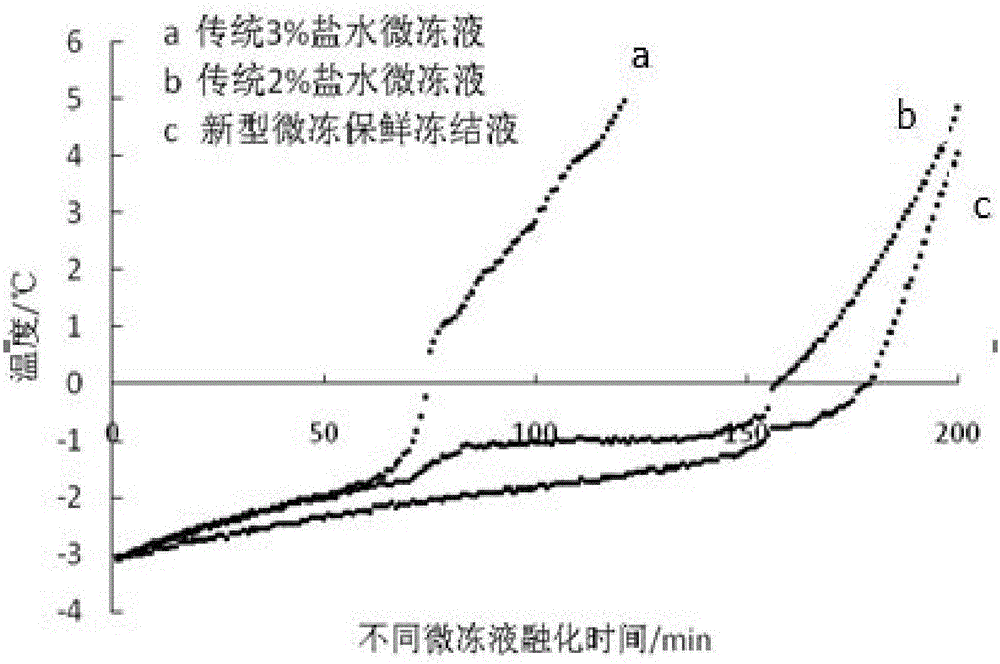

[0020] The product is kept at -3~-1.5°C for 104 minutes (see figure 1 ), and the maintenance time of 2% and 3% brine ice in the slightly freezing temperature zone is 74 and 67 minutes respectively (see figure 2 ).

Embodiment 2

[0022] The formula of ice for micro freezing and fresh keeping: 0.5% sodium chloride, 2.0% propylene glycol, 1.0% sodium polyacrylate, and 96.5% water.

[0023] The preparation process is the same as in Example 1.

[0024] The product is kept at -3~-1.5°C for 140 minutes (see figure 1 , figure 2 ). And the brine ice of 2% and 3% concentration is respectively 74min and 67min in slightly freezing temperature zone-3~-1.5 ℃ (see figure 2 ).

Embodiment 3

[0026] The formula of ice for micro freezing and fresh keeping: 0.5% sodium chloride, 2.0% propylene glycol, 0.5% sodium polyacrylate, and 97% water.

[0027] During the preparation process of fresh-keeping ice, sodium polyacrylate is first dissolved with propylene glycol, then mixed with sodium chloride and water to make a mixed solution, and then made into ice.

[0028] The product is kept at -3~-1.5°C for 127 minutes (see figure 1 ). And 2% and 3% concentration of salt water ice are respectively 74 and 67 minutes in the slightly freezing temperature zone -3--1.5 ℃ (see figure 2 ).

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com