Non-bitter low-sodium umami salt and preparation method thereof

A technology of non-bitter, umami-tasting salt, applied in the field of edible sodium chloride, which can solve the problems of damage to health, insignificant increase in saltiness, low intensity of salty taste, etc., and achieve the effects of increasing acidity, good soothing effect, and increasing flavor and taste

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

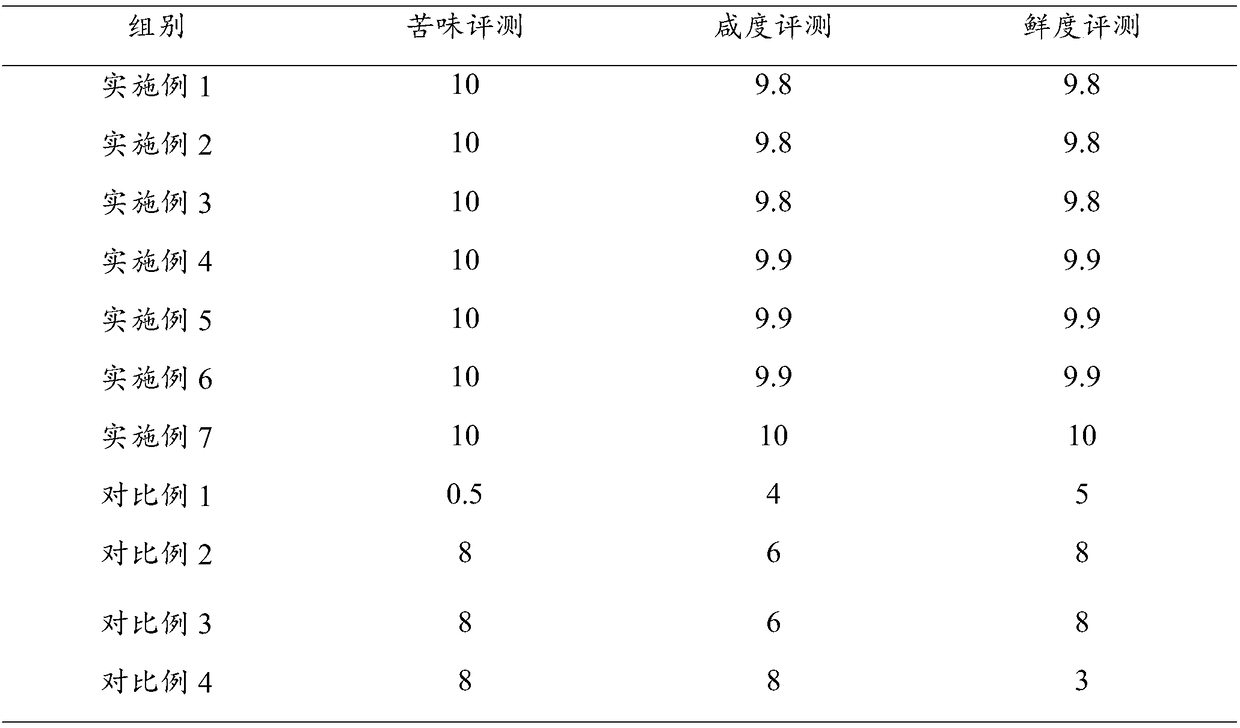

Examples

Embodiment 1

[0044] Example 1: Non-bitter low-sodium umami salt

[0045] 1. In parts by weight, the non-bitter and low-sodium umami salt (named Jianyi light salt) of the present embodiment is composed of the following components:

[0046] 45 parts of edible potassium chloride, 35 parts of edible sodium chloride, 10 parts of trehalose, 1 part of disodium malate, 8.9 parts of sodium gluconate, and 0.1 part of L-alanine.

[0047] 2, the preparation method of described non-bitter taste low-sodium umami salt (named after Jianyi light salt) comprises the steps:

[0048] Step 1: Screening raw materials: sieve all the required raw materials into 0.15mm-0.85mm particles;

[0049] Step 2: Take the potassium chloride, edible sodium chloride, trehalose, disodium malate, sodium gluconate and L-alanine screened in the step 1 respectively according to the proportioning relationship, and mix uniform;

[0050] Step 3, measuring and packaging after the mixture is prepared;

[0051] Step 4, packing, stac...

Embodiment 2

[0052] Example 2: Non-bitter low-sodium umami salt

[0053] 1. In parts by weight, the non-bitter and low-sodium umami salt (named Jianyi light salt) of the present embodiment is composed of the following components:

[0054] 50 parts of edible potassium chloride, 45 parts of edible sodium chloride, 1 part of trehalose, 1 part of disodium malate, 1 part of sodium gluconate, and 2 parts of L-alanine.

[0055] 2, the preparation method of described non-bitter taste low-sodium umami salt (named after Jianyi light salt) comprises the steps:

[0056] Step 1: Screening raw materials: sieve all the required raw materials into 0.15mm-0.85mm particles;

[0057] Step 2: Take the potassium chloride, edible sodium chloride, trehalose, disodium malate, sodium gluconate and L-alanine screened in the step 1 respectively according to the proportioning relationship, and mix uniform;

[0058] Step 3, measuring and packaging after the mixture is prepared;

[0059] Step 4, packing, stacking, ...

Embodiment 3

[0060] Example 3: Non-bitter low-sodium umami salt

[0061] 1. In parts by weight, the non-bitter and low-sodium umami salt (named Jianyi light salt) of the present embodiment is composed of the following components:

[0062] 45 parts of edible potassium chloride, 35 parts of edible sodium chloride, 1 part of trehalose, 10 parts of disodium malate, 4 parts of sodium gluconate, and 5 parts of L-alanine.

[0063] 2, the preparation method of described non-bitter taste low-sodium umami salt (named after Jianyi light salt) comprises the steps:

[0064] Step 1: Screening raw materials: sieve all the required raw materials into 0.15mm-0.85mm particles;

[0065] Step 2: Take the potassium chloride, edible sodium chloride, trehalose, disodium malate, sodium gluconate and L-alanine screened in the step 1 respectively according to the proportioning relationship, and mix uniform;

[0066] Step 3, measuring and packaging after the mixture is prepared;

[0067] Step 4, packing, stackin...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com