Preparation technology of solar salt

A preparation process and brine technology, applied in the direction of alkali metal chloride, etc., can solve problems such as uneven particle size, complicated production process, and insufficient stability, and achieve the effects of low sodium chloride content, uniform product particle size, and simple process

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

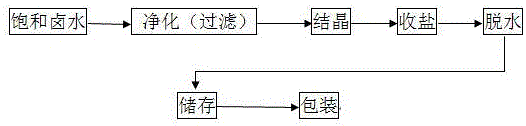

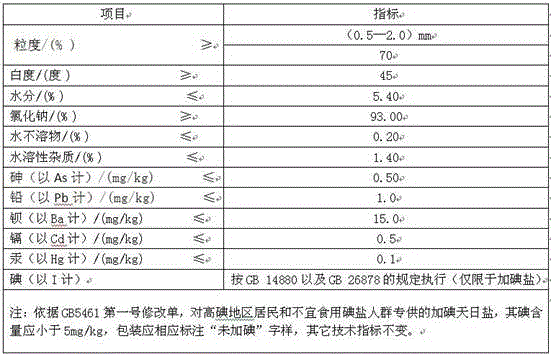

[0013] The production process flow of the present invention: put pure saturated brine into the purification pool for filtration, add it into the crystallization pool after purification, and precipitate sodium chloride through natural evaporation and crystallization, during which salt rotation and rotation are carried out according to the evaporation amount and the particle size of the salt. Brine, so that the salt particles are uniform, and the salt is collected when the salt particles reach 0.5~2.0mm. Then dry and dehydrate, store and pack for sale.

[0014] The specific steps are: Step 1: Use seawater to make saturated brine (the ratio of sodium to magnesium is greater than 3), transport the saturated brine to the purification tank through pipelines for filtration and purification, and filter out biological dead bodies and plant residues (various algae and weeds, etc.) and atmospheric dust, etc.;

[0015] Step 2: The purified brine is added to the crystallization pool depen...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com