Preparation method of low-sodium fine grain alumina

A technology of fine-crystalline alumina and aluminum hydroxide, which is applied in the field of preparation of low-sodium fine-crystalline alumina, can solve the problems of difficulty in filtering, washing, drying, complicated salting-out purification process, and high requirements on corrosion resistance, and achieves production cost. Low, wide source of raw materials, the effect of simplifying the production process

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

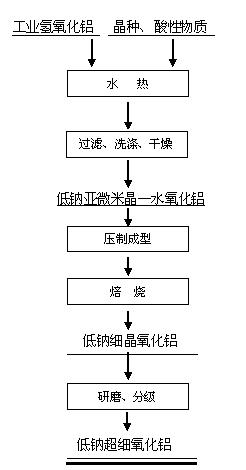

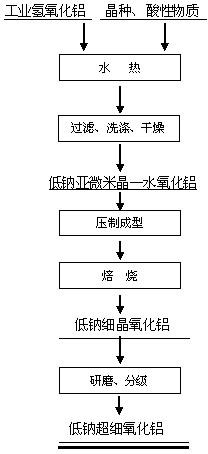

Image

Examples

preparation example Construction

[0021] A method for preparing low-sodium fine-grained alumina, which involves fully mixing industrial aluminum hydroxide and pseudo-boehmite (or boehmite) seed crystals to form a slurry, which is carried out at a certain temperature in a hydrothermal reaction device. Hydrothermal reaction, after which the slurry is filtered, washed, and dried to obtain low-sodium fine-grained alumina monohydrate, and then the alumina monohydrate is pressed into bricks or balls by a brick press or ball making machine, and placed in a flint kiln The powder is calcined at a certain temperature in a shuttle kiln or other calcining kilns to prepare low-sodium fine-grained alumina. After further grinding and classification, low-sodium submicron alumina powder can be obtained.

[0022] The process is as follows: firstly, industrial aluminum hydroxide and pure water or tap water are prepared into a slurry with a certain solid content, and seeds can be added and the pH value of the slurry can be adjuste...

Embodiment 1

[0024] Add 10 tons of industrial aluminum hydroxide (average particle size of 65 microns) into the batching tank, add 50 cubic meters of tap water, stir the slurry to fully mix, and then transport the slurry to the pipeline device by a diaphragm pump. After the slurry is gradually preheated to 220°C in the pipeline, it enters the high-pressure reactor for hydrothermal reaction. The slurry stays in the high-pressure reactor for 60 minutes, and then the slurry is flashed and cooled to 98 by flash tank. ℃. After the reaction, the slurry enters the buffer tank, and the slurry is transported to the vacuum belt filter by the slurry pump for filtration and washing. The obtained alumina monohydrate is pressed and formed by a brick press, and then placed on the SiC shed plate, and then placed on the shuttle-type Calcined in the kiln at 1250°C and kept at 1250°C for 6 hours to obtain high-temperature alumina with an α-phase transformation rate greater than 95%. Observation by scanning e...

Embodiment 2

[0026] Add 10 tons of industrial aluminum hydroxide (average particle size of 65 microns) into the batching tank, add 50 cubic meters of tap water, stir the slurry to fully mix, and then transport the slurry to the pipeline device by a diaphragm pump. After the slurry is gradually preheated to 240°C in the pipeline, it enters the high-pressure reactor for hydrothermal reaction. The slurry stays in the high-pressure reactor for 30 minutes, and then the slurry is flashed and cooled to 98 by flash tank. ℃. After the reaction, the slurry enters the buffer tank, and the slurry is transported to the vacuum belt filter by the slurry pump for filtration and washing. The obtained alumina monohydrate is pressed and formed by a brick press, and then placed on the SiC shed plate, and then placed on the shuttle-type Calcined in a kiln at 1250°C and held at 1350°C for 6 hours to obtain high-temperature alumina with an α-phase conversion rate greater than 95%. Observation by a scanning elect...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Granularity | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com